Quartz stone grinding system for quartz stone precision machining

A technology of precision machining and quartz stone, applied in the direction of grain processing, etc., can solve the problems of no crushing and screening, damage, no cooling and dust reduction, etc., to speed up the screening speed, reduce the dust dispersion, and improve the grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

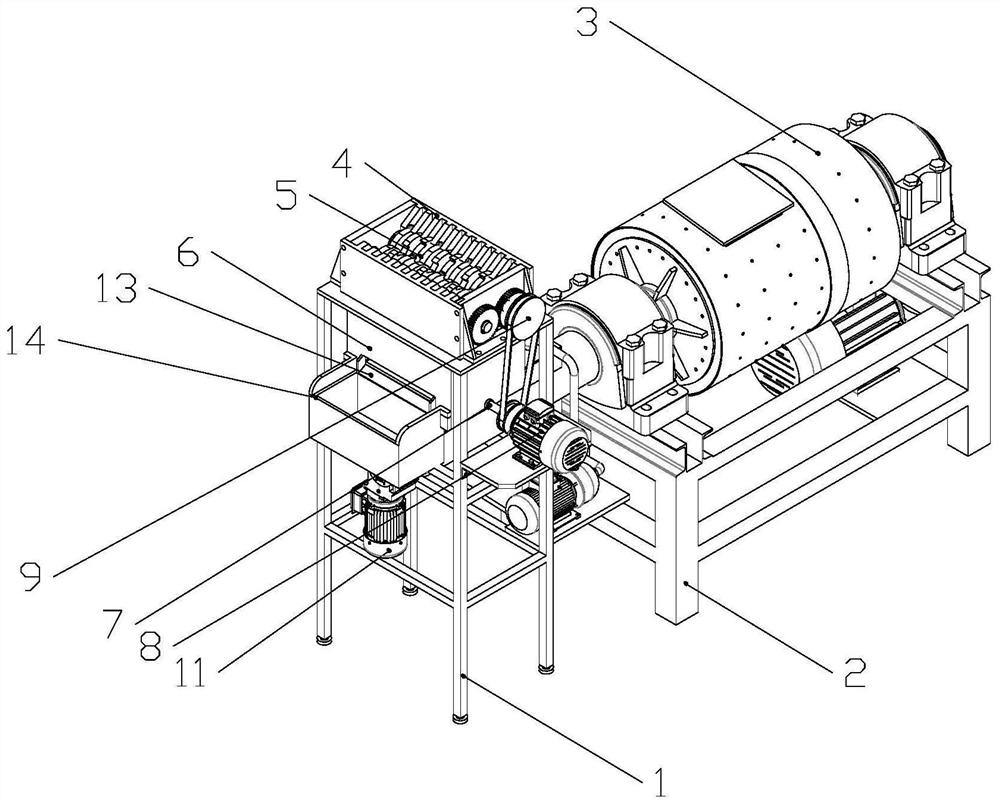

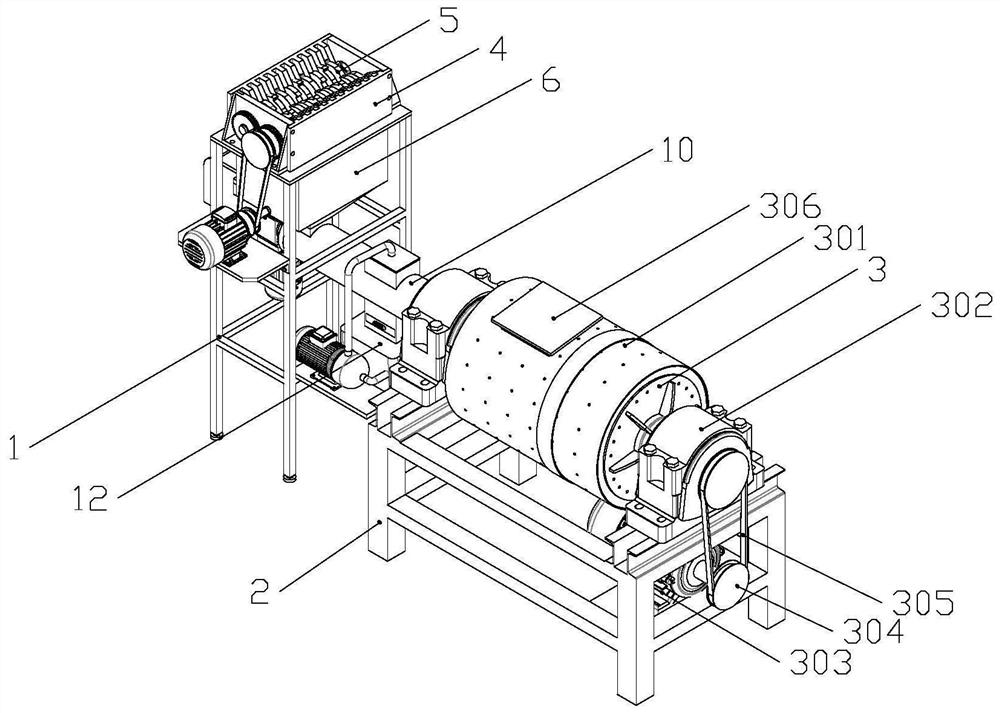

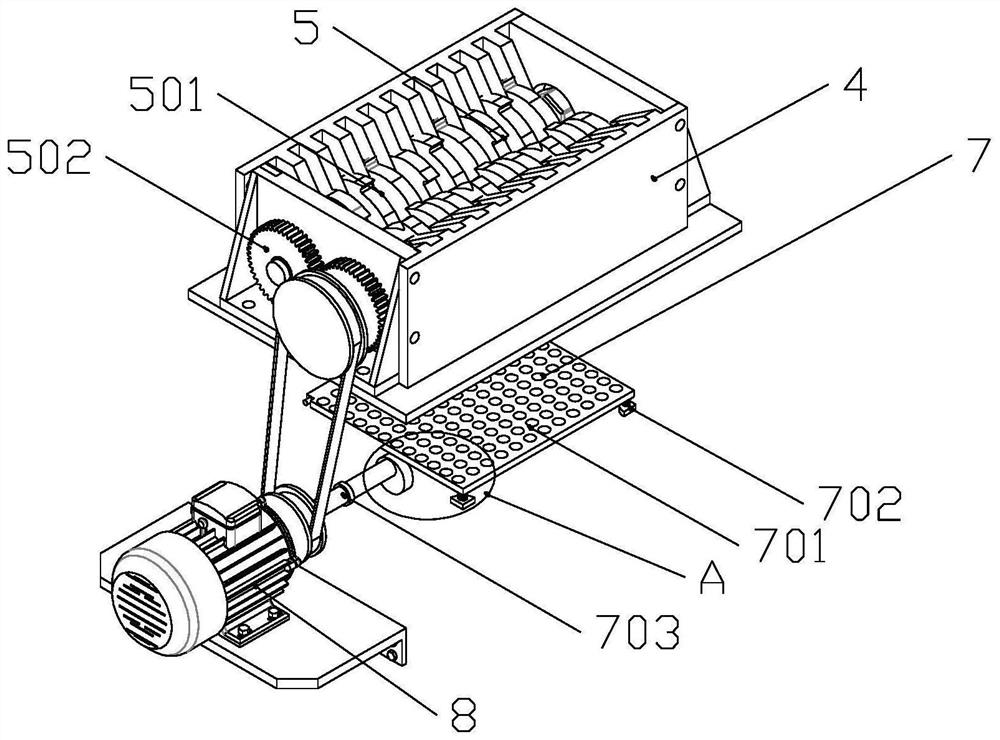

[0049] Example: Figure 1 - Figure 6 Design, a quartz stone grinding system is used for a quartz stone grinding system, including a support frame one, a support frame 2 2, and a abrasive assembly 3, and the top of the support frame 1 is fixedly mounted with a striped box 4, and the interior setting of the crushing box 4 There is a pulverizing assembly 5, the bottom of the pulverizer 4 is connected to the screen partition box 6, and the screen partition assembly 7 is provided inside, and one end of the screening assembly 7 is transmitted through the coupling. A transmission assembly 9 is provided between the assembly 7 and the pulverizing assembly 5, and the screen cleaning tank 6 is connected through the bottom of the feed tube 10, and the inside of the feed tube 10 is provided with a transport assembly 11, and the dust collecting assembly 12 is provided in the middle position of the feed tube 10. One end of the tube 10 extends to the inside of the abrasive assembly 3, and the abra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com