Pre-selection process of high-mud hematite iron ore

An iron ore and process technology, which is applied in the field of high-mudity hematite ore and the pre-selection process of high-mudity hematite ore, can solve the problems of unsatisfactory pre-selection effect of high-mudity hematite ore, etc. Efficient preselection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

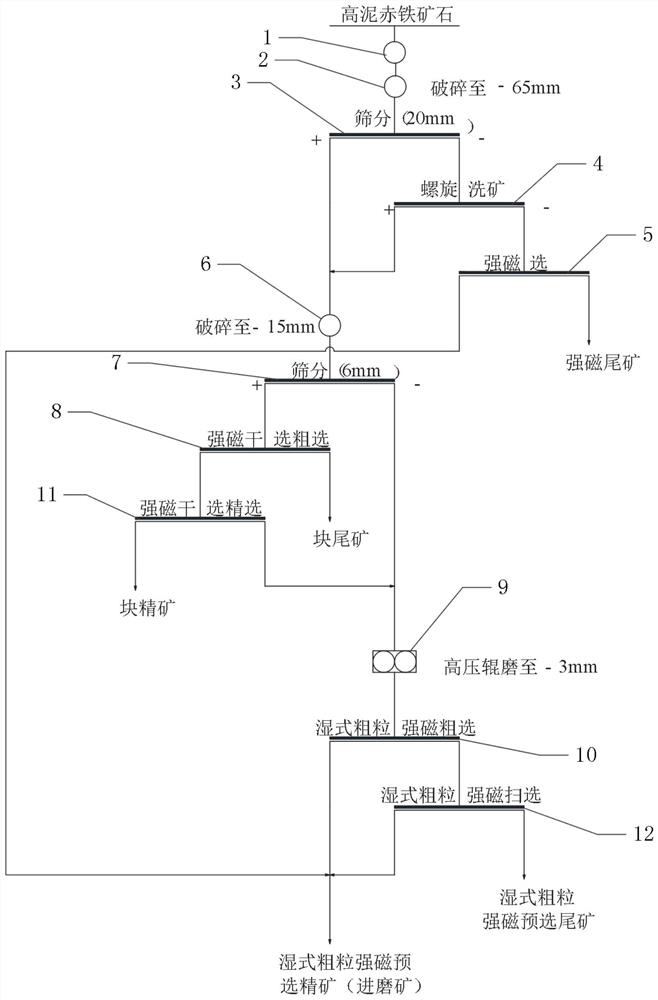

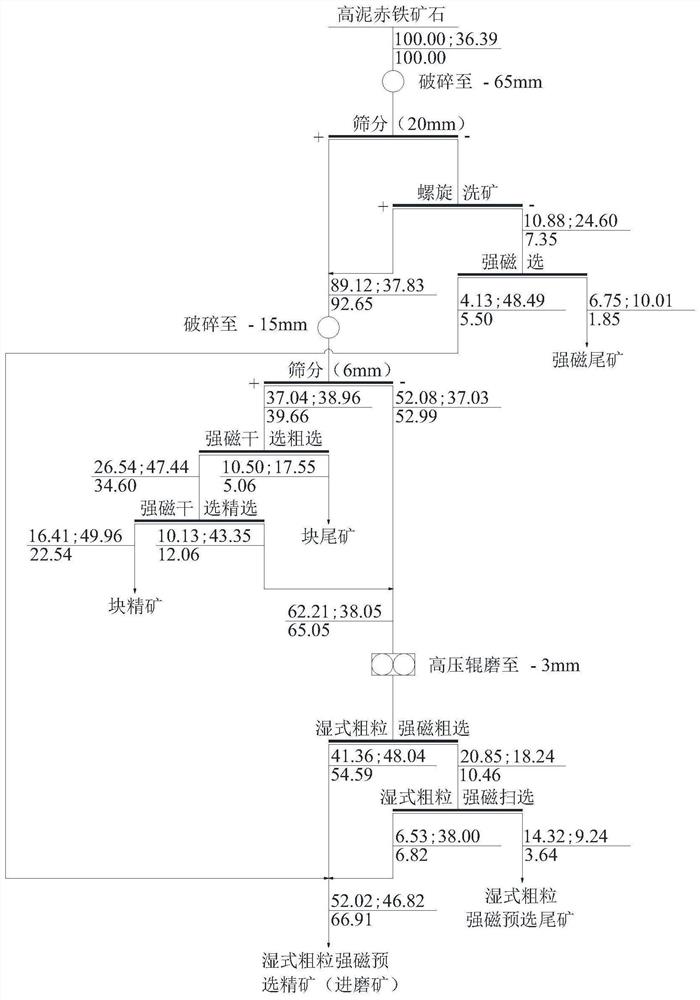

[0035] as attached figure 1 Shown, the pre-selection process of a kind of high-mud hematite ore of the present invention, at first the ore that is mined is through coarse crushing, medium crushing to -65mm grain grade to satisfy the ore supply condition of described pre-selection process, and adopt following process:

[0036] S1. Dry-screen the secondary crushed product with a particle size of -65mm to obtain two product grades of -65+20mm and -20mm;

[0037] S2. Washing and desliming the -20mm particle size product obtained in step S1 and performing strong magnetic separation on the overflow of the ore washing to obtain strong magnetic separation concentrate and strong magnetic separation tailings;

[0038] S3. Combine the -65+20mm particle size product obtained in step S1 with the ore washing and return sand in step S2 and crush it to -15mm, then perform dry screening to obtain two particle size products of -15+6mm and -6mm ;

[0039] S4. The -15+6mm particle size product ...

Embodiment 2

[0049] The high-mud hematite ore was taken from an iron mine in Anhui. The results of chemical multi-element analysis of the raw ore are shown in Table 1, and the results of iron phase analysis are shown in Table 2.

[0050] Table 1 Chemical multi-element analysis results of high-mud hematite ore (%)

[0051] Laboratory items content(%) Laboratory items content(%) TF 36.29 Na 2 o

0.465 SiO 2

31.45 MnO 0.122 Al 2 o 3

5.91 V 2 o 5

0.126 CaO 2.82 TiO 2

0.317 MgO 0.863 CuO <0.005

S 0.068 ZnO 0.024 P 0.633 Cr 2 o 3

<0.005

K 2 o

0.617 NiO <0.005

[0052] Table 2 Iron phase analysis results of high-mud hematite ore (%)

[0053] iron phase Iron phase iron content share magnetite iron 0.67 1.85 hematite iron 34.51 95.15 pyrite iron 0.19 0.52 pyrrhotite iron / / Iron Carbonate 0.60 1.65 iron ferrosilicate ...

Embodiment 3

[0063] The present invention is a preselection system for high-mud hematite ore, which includes coarse crushing equipment 1, medium crushing equipment 2, first screening equipment 3, ore washing equipment 4, strong magnetic separation equipment 5, crushing equipment 6, the second Screening equipment 7, strong magnetic dry separation roughing equipment 8, strong magnetic dry separation selection equipment 11, high-pressure roller mill 9, wet coarse-grained strong magnetic roughing equipment 10 and wet-type coarse-grained strong magnetic sweeping equipment 12; The discharge port of the coarse crushing equipment 1 is connected with the feed port of the secondary crushing device 2; the discharge port of the secondary crushing device 2 is connected with the feed port of the first screening device 3; the first screening device 3 The fine-grained product outlet of the ore washing device 4 is connected to the feeding port of the ore washing equipment 4, and its coarse-grained product o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com