Masonry cement applicable to home decoration and production method therefor

A technology of masonry cement and manufacturing method, which is applied in the direction of cement production, etc. It can solve the problems of being unsuitable for home decoration, increasing the color depth of cement products, and affecting the color aesthetics of cement products, so as to reduce metal loss, low harmful component content, The effect of improving the aesthetics of the color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

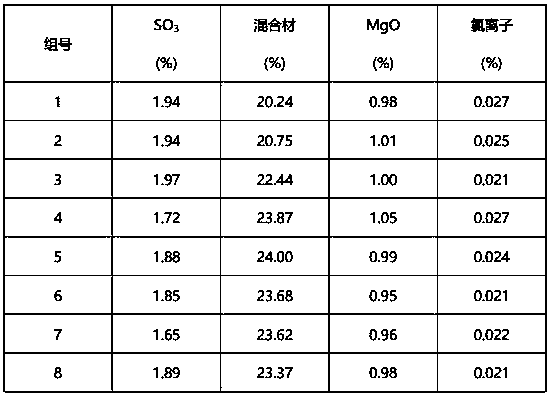

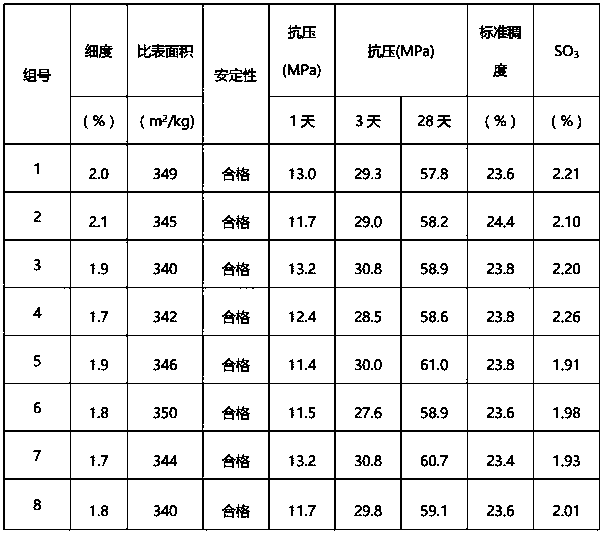

Examples

Embodiment 1

[0028] This embodiment provides a masonry cement suitable for home decoration and a manufacturing method thereof. Specifically, the manufacturing method of the masonry cement includes the following steps:

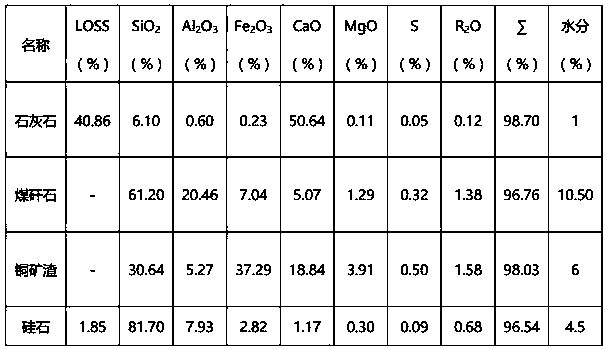

[0029] S1. Weigh 0.8t of limestone, 0.13t of coal gangue, 0.06t of copper slag and 0.01t of silica, and set aside.

[0030] S2. Mix the weighed limestone, coal gangue, copper slag and silica together, and grind until the sieve residue after passing through an 80 μm square hole sieve is 5%, to obtain raw meal.

[0031] S3. After homogenizing the raw meal, it is placed in the five-stage cyclone pre-decomposition system of the existing dry-process cement kiln system, and preheated and decomposed by high-temperature oxygen-poor combustion technology; the temperature control of the pre-heated decomposed process At 860°C, specifically, the outlet temperature of the first-stage cylinder of the five-stage cyclone pre-decomposition system is controlled at 360°C, and then the compreh...

Embodiment 2

[0036] This embodiment provides a masonry cement suitable for home decoration and a manufacturing method thereof. Specifically, the manufacturing method of the masonry cement includes the following steps:

[0037] S1. Weigh 0.9t of limestone, 0.079t of coal gangue, 0.02t of copper slag and 0.001t of silica, and set aside.

[0038] S2. Mix the weighed limestone, coal gangue, copper slag and silica together, and grind until the sieve residue after passing through an 80 μm square hole sieve is 20%, to obtain raw meal.

[0039] S3. After homogenizing the raw meal, it is placed in the five-stage cyclone pre-decomposition system of the existing dry-process cement kiln system, and preheated and decomposed by high-temperature oxygen-poor combustion technology; the temperature control of the pre-heated decomposed process At 890°C, specifically, the outlet temperature of the first-stage cylinder of the five-stage cyclone pre-decomposition system is controlled at 370°C, and then the comp...

Embodiment 3

[0044]This embodiment provides a masonry cement suitable for home decoration and a manufacturing method thereof. Specifically, the manufacturing method of the masonry cement includes the following steps:

[0045] S1. Weigh 0.823t of limestone, 0.12t of coal gangue, 0.05t of copper slag and 0.007t of silica, and set aside.

[0046] S2. Mix the weighed limestone, coal gangue, copper slag and silica together, and grind until the sieve residue after passing through an 80 μm square hole sieve is 10%, to obtain raw meal.

[0047] S3. After homogenizing the raw meal, it is placed in the five-stage cyclone pre-decomposition system of the existing dry-process cement kiln system, and preheated and decomposed by high-temperature oxygen-poor combustion technology; the temperature control of the pre-heated decomposed process At 880°C, specifically, the outlet temperature of the first-stage cylinder of the five-stage cyclone pre-decomposition system is controlled at 365°C, and secondly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com