Method for deironing through oxygen

An oxygen and iron slag technology, applied in the field of hydrometallurgy, can solve the problems of large metal loss, uneven oxygen distribution, low iron content in iron slag, etc., and achieve the effect of reducing metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

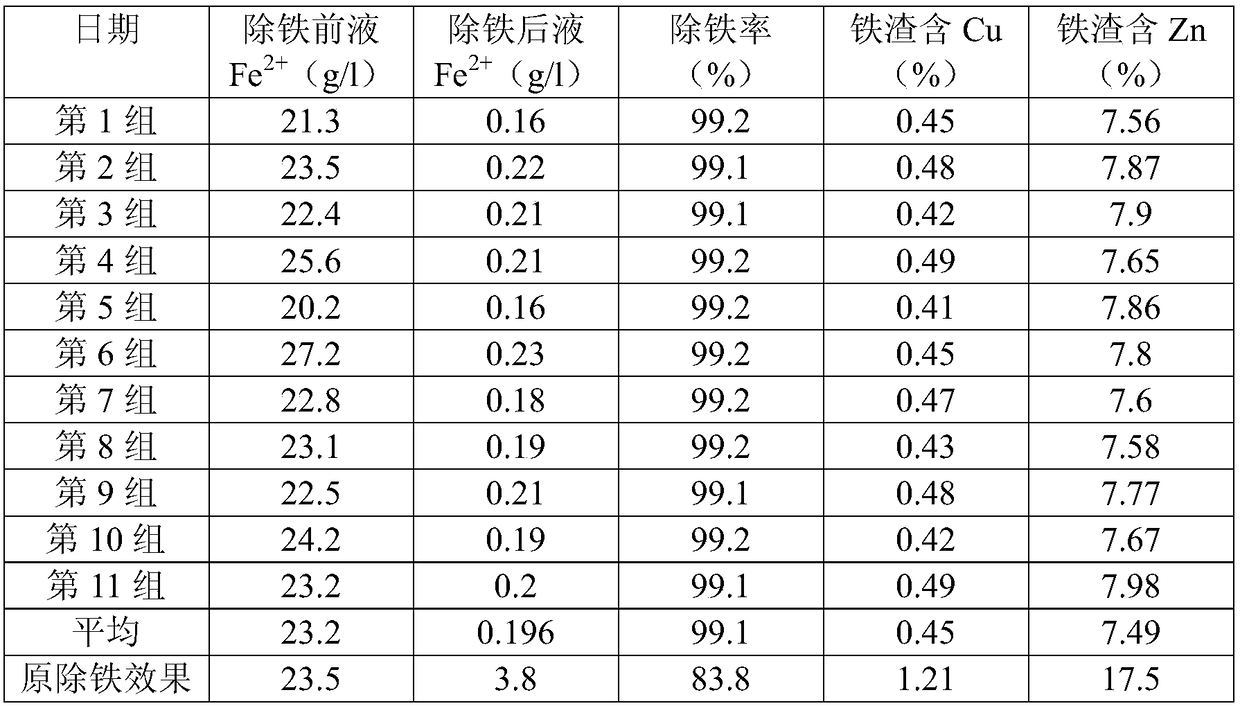

Examples

Embodiment 1

[0017] A method for removing iron from oxygen, including the following steps:

[0018] (1) Using calcine to control the pH value of the zinc-copper mixed solution in the reactor at 2.9;

[0019] (2) The stirring shaft is set vertically with the reactor, and oxygen is transported to the bottom of the reactor through the center of the stirring shaft, and the oxygen and the zinc-copper mixed solution are fully mixed by the stirring shear force;

[0020] (3) The product obtained in step (2) is passed to an iron removing thickener for precipitation separation, and the solution and iron slag are obtained by filtration and separation.

Embodiment 2

[0022] A method for removing iron from oxygen, including the following steps:

[0023] (1) Use calcine to control the pH value of the zinc-copper mixed solution in the reactor at 3;

[0024] (2) The stirring shaft is set vertically with the reactor, and oxygen is transported to the bottom of the reactor through the center of the stirring shaft, and the oxygen and the zinc-copper mixed solution are fully mixed by the stirring shear force;

[0025] (3) The product obtained in step (2) is passed to an iron removing thickener for precipitation separation, and the solution and iron slag are obtained by filtration and separation.

Embodiment 3

[0027] A method for removing iron from oxygen, including the following steps:

[0028] (1) Use calcine to control the pH value of the zinc-copper mixed solution in the reactor at 3.1;

[0029] (2) The stirring shaft is set vertically with the reactor, and oxygen is transported to the bottom of the reactor through the center of the stirring shaft, and the oxygen and the zinc-copper mixed solution are fully mixed by the stirring shear force;

[0030] (3) The product obtained in step (2) is passed to an iron removing thickener for precipitation separation, and the solution and iron slag are obtained by filtration and separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com