Recycling device for demolition steel of steel structure building

A steel structure and building technology, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low processing efficiency, inability to cut disk positioning and cutting, etc., to ensure stability and facilitate the effect of supporting the limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

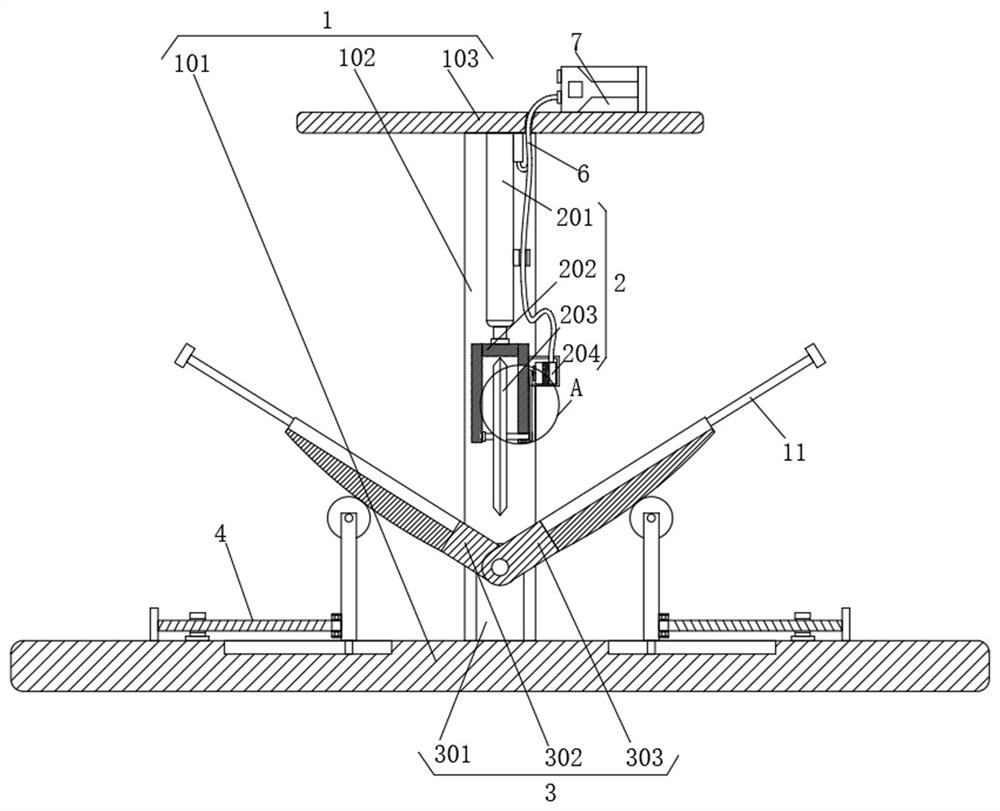

[0033] see figure 1 , figure 2 with image 3 , the steel structure demolition steel recycling device of the present invention includes a fixing assembly 1, a cutting assembly 2 and a supporting assembly 3, the fixing assembly 1 includes a base 101, a main rod 102 and a fixing plate 103, and the main rod 102 is fixedly installed on the base 101 The top of the top, the fixed plate 103 is fixedly installed on the top of the main rod 102, the cutting assembly 2 is fixedly installed on the bottom of the fixed plate 103, the support assembly 3 is arranged on the top of the base 101, and the bottom of the support assembly 3 is provided with an adjustment assembly 4.

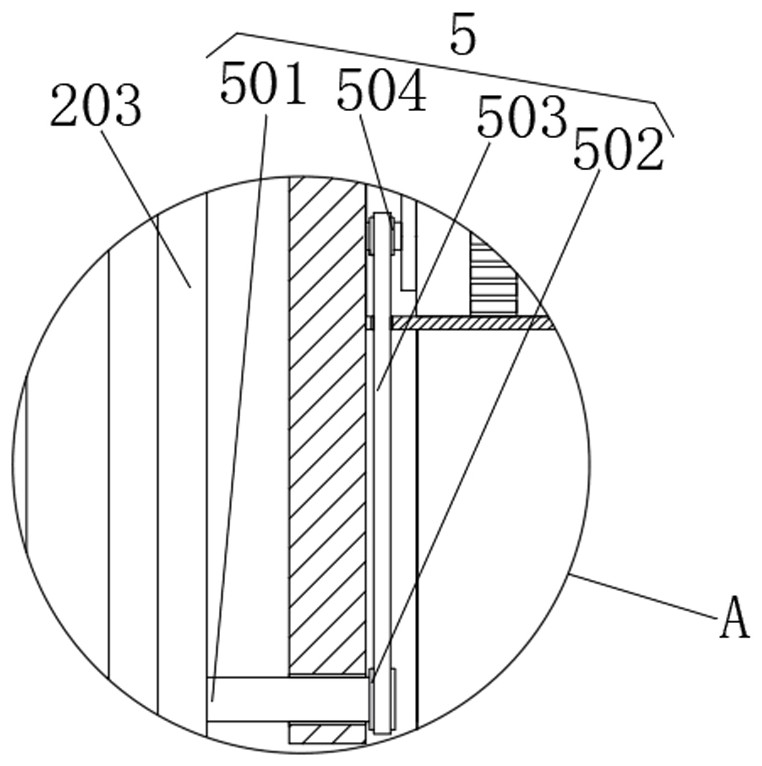

[0034] Cutting assembly 2 comprises electric telescopic rod 201, mounting bracket 202, cutting disc 203 and motor 204, and electric telescopic rod 201 is fixedly installed on the bottom of fixed plate 103, and mounting frame 202 is fixedly installed on the bottom of electric telescopic rod 201, and cutting disc 203 is...

Embodiment 2

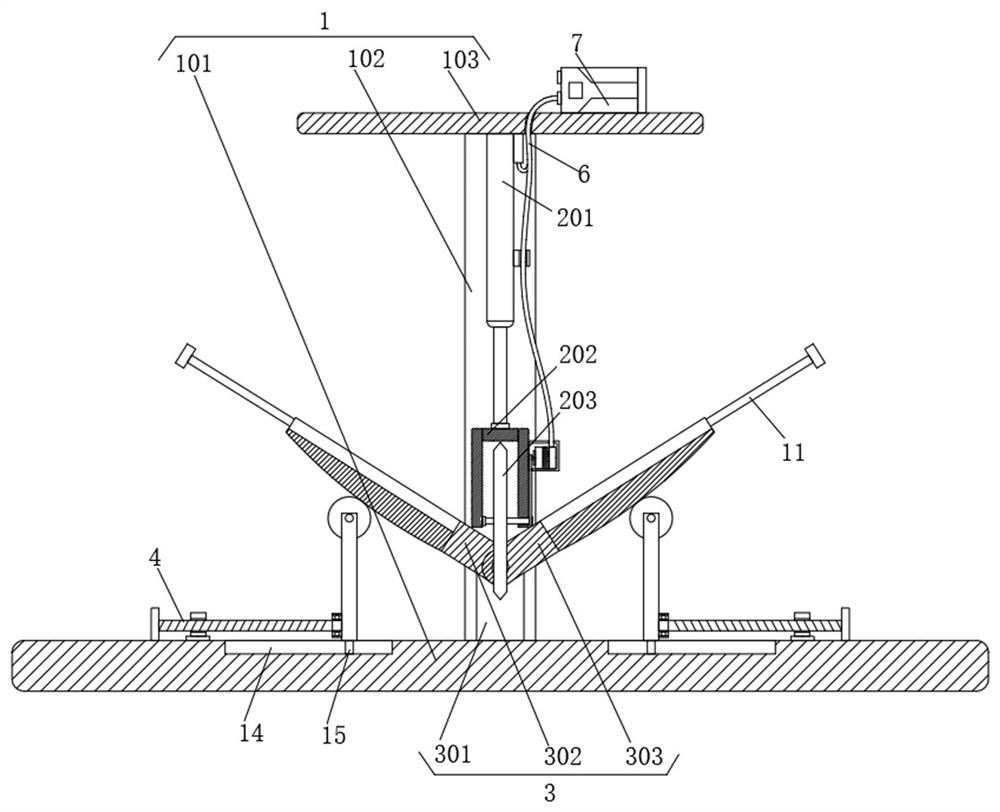

[0038] see figure 1 , Figure 4 and Figure 5 , the support assembly 3 includes a support column 301, a first support plate 302 and a second support plate 303, the support column 301 is fixedly installed on the top of the base 101, and the first support plate 302 and the second support plate 303 are both movably installed on the support through hinges. At the top of the column 301, the top surfaces of the first support plate 302 and the second support plate 303 are provided with a placement groove 8, and the sides of the first support plate 302 and the second support plate 303 are provided with concave holes 9, and the first support plate 302 and the side of the second support plate 303 are all movably connected with a movable frame 10, and the inwall of the movable frame 10 is fixedly connected with a push rod 11, and one end of the push rod 11 is inserted into the inside of the first support plate 302 and the second support plate 303, placed The inner wall of the groove 8 ...

Embodiment 3

[0042] see figure 1 , figure 2 and Figure 6 , the adjustment assembly 4 comprises a threaded rod 401, a movable plate 402 and a roller 403, a bearing is arranged between one end of the threaded rod 401 and the side of the movable plate 402, and the roller 403 is installed on the top of the movable plate 402 by rotating the rotating shaft, and the surface of the roller 403 Fitted with the bottom surface of the first support plate 302 and the second support plate 303, the top surface of the base 101 is provided with a chute 14, the inner wall of the chute 14 is movably connected with a slider 15, and the top of the slider 15 is connected with the movable plate 402. Fixed connection at the bottom.

[0043] The difference from Embodiment 2 is that an adjustment assembly 4 is provided at the bottom of the first support plate 302 and the second support plate 303, so that the threaded rod 401 on the adjustment assembly 4 drives the movable plate 402 to move left and right, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com