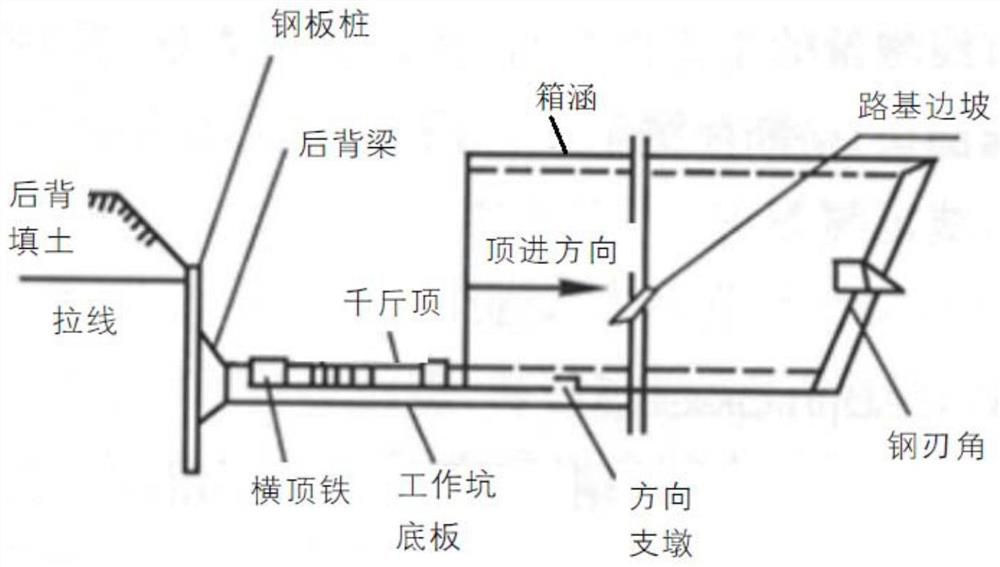

Construction method and construction device for box culvert jacking

A construction method and technology of construction devices, which are applied in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of many processes, difficulty in accurately positioning steel trusses and steel bottom plates, and many manual labors, etc., and achieve high adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

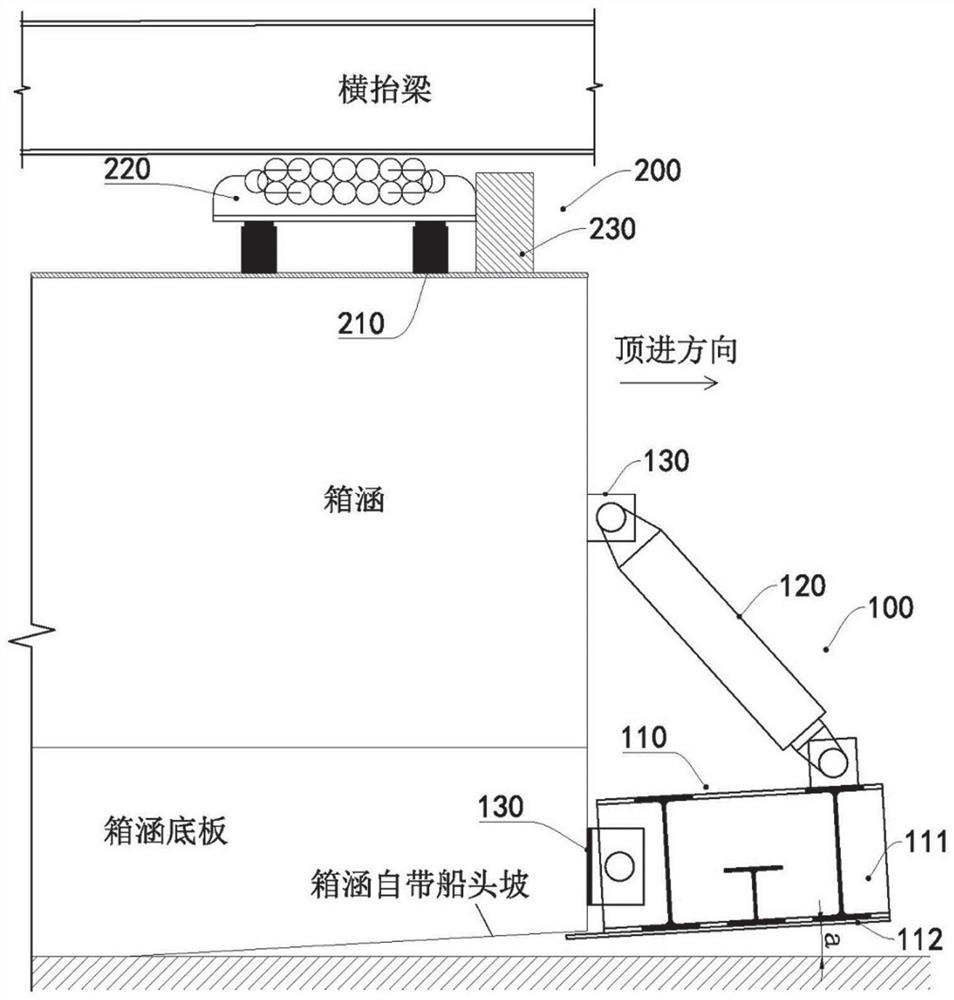

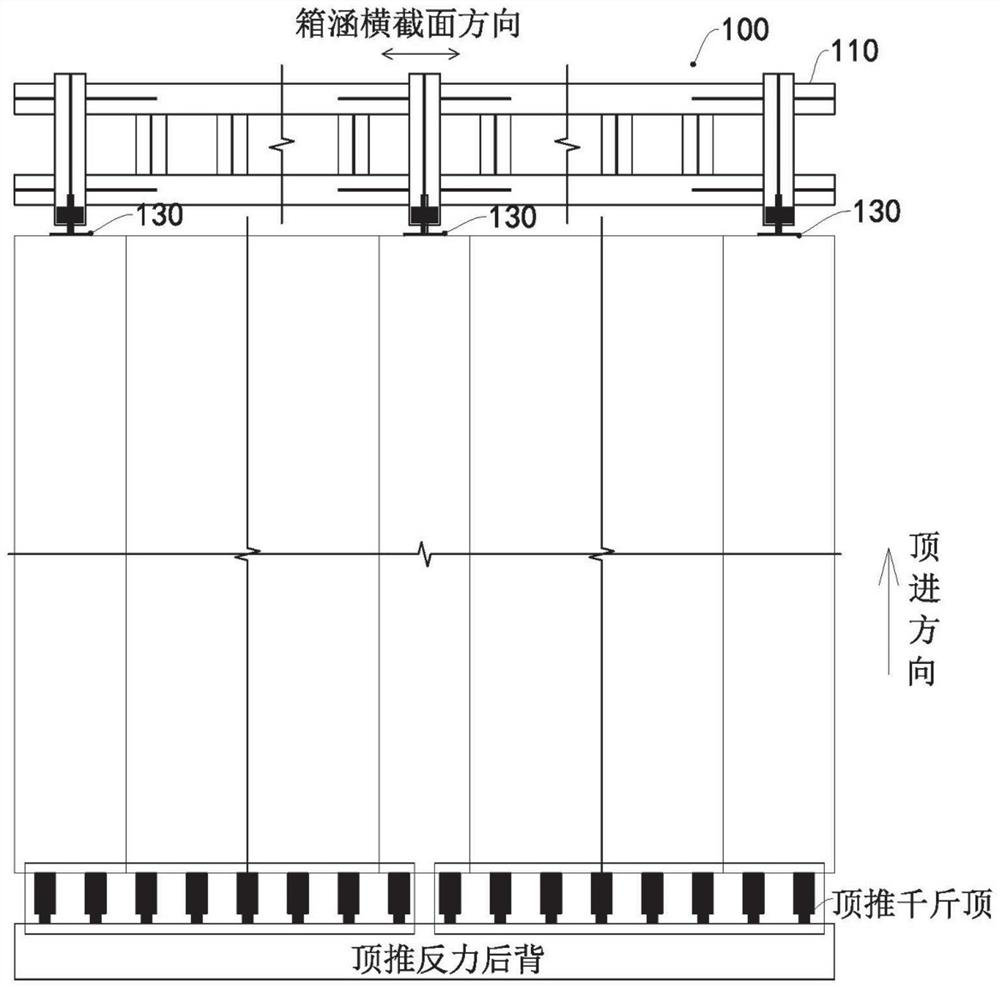

[0032] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0033] The construction device of box culvert jacking of the present invention, as figure 2 As shown, including adjustable angle bow ramp 100.

[0034]The angle-adjustable bow slope 100 is installed at the front end of the box culvert, and includes a steel bow slope 110, a plurality of jacks 120 and multiple sets of connectors 130 connecting the steel bow slope 110 and the box culvert.

[0035] Each set of connecting pieces 130 includes a connecting piece 130 fixed on the front riser of the box culvert and a connecting piece 130 directly below fixed on the front end of the bottom plate of the box culvert. Preferably, the connecting piece 130 is installed by pre-embedding or chemical anchor bolts.

[0036] See figure 2 , in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com