Silencer and compressor

A muffler and compressor technology, applied in the field of compressors, can solve problems such as the threat of pump body lubrication and low compressor superheat, and achieve the effects of solving insufficient superheat, increasing heat exchange, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

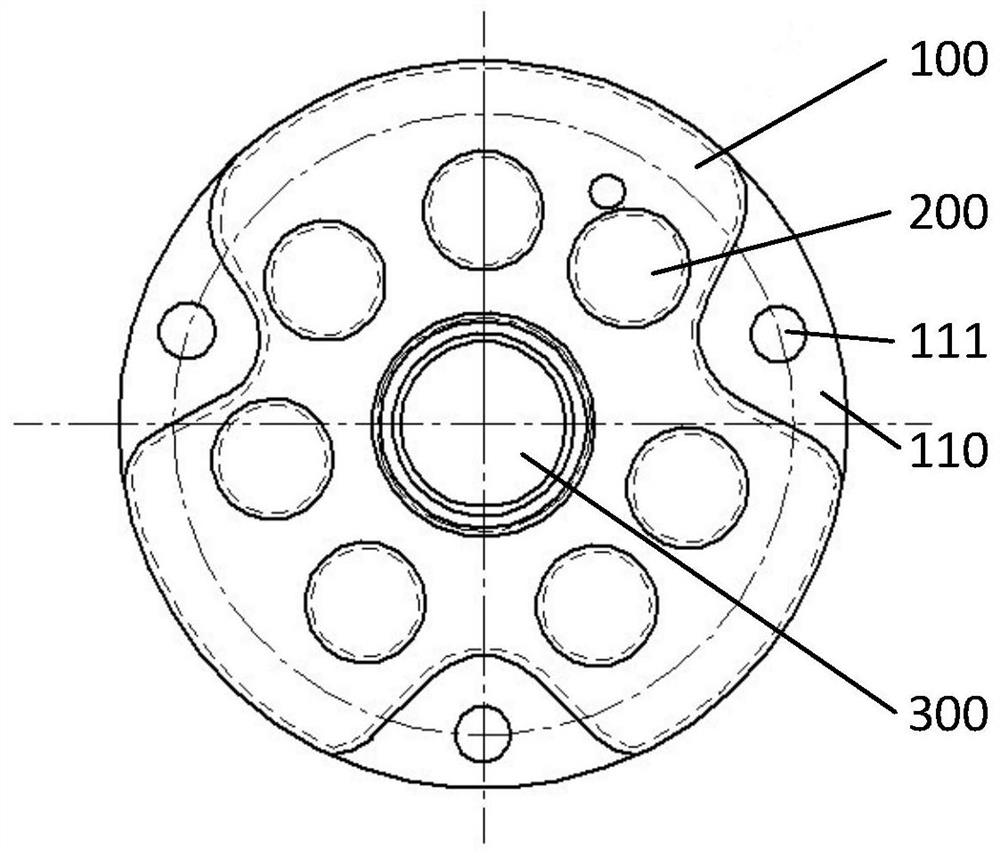

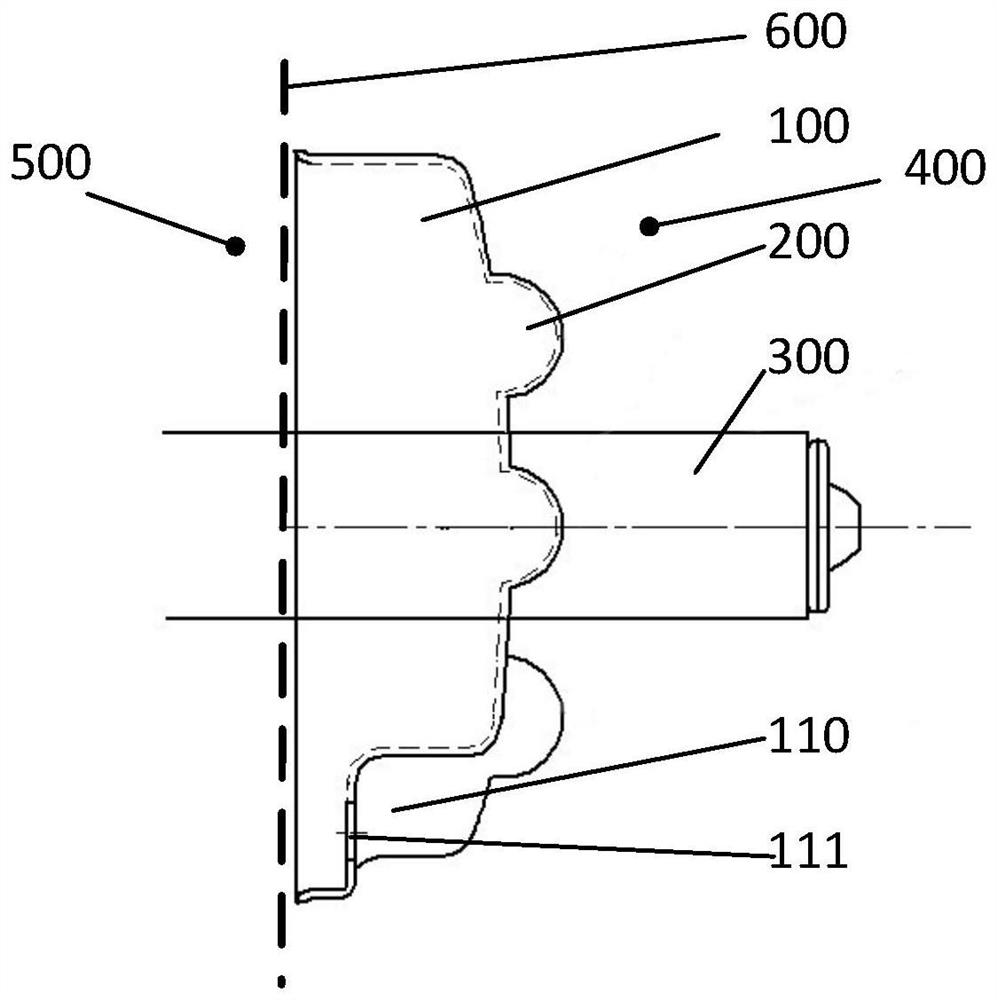

[0029] Please refer to figure 1 and figure 2 ,in, figure 1 It is the front view of the muffler of Embodiment 1 of the present invention; figure 2 It is the left side view of the muffler of Embodiment 1 of the present invention.

[0030] figure 1 and figure 2 A muffler is shown, which is applied to a compressor; the muffler is arranged between the oil storage part 400 and the refrigerant discharge chamber 500, and the muffler includes a main body 100 arranged in the axial direction and at least one protrusion 200, the raised portion 200 is arranged axially on the main body 100, and protrudes toward the oil storage portion 400; the contour of the projection of the raised portion 200 on a base surface 600 falls on the The main body 100 is within the outline of the projection on the base surface 600 . The base surface 600 is a reference surface perpendicular to the central axis of the muffler.

[0031] Among the existing compressors, there is a type of compressor that di...

Embodiment 2

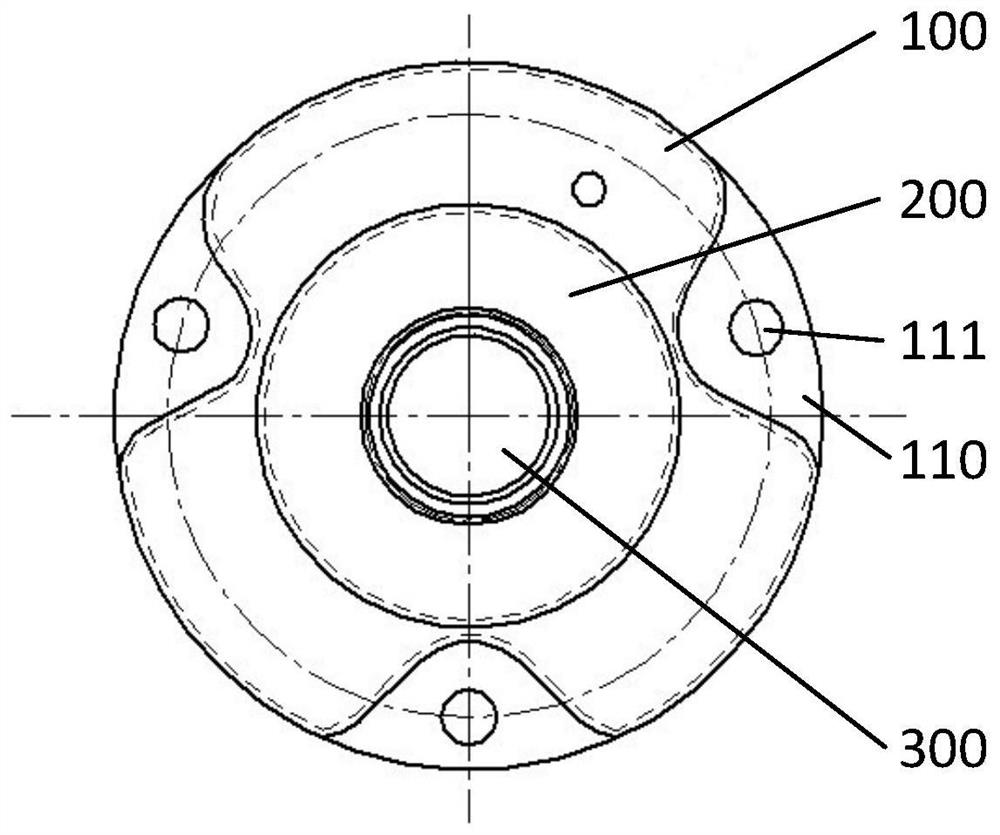

[0044] Please refer to image 3 and Figure 4 ,in, image 3 It is the front view of the muffler of Embodiment 2 of the present invention; Figure 4 It is the left side view of the muffler of the second embodiment of the present invention.

[0045] The difference between this embodiment and the first embodiment is that the protruding portion 200 includes a circular cylinder, and the axis of the circular cylinder coincides with the axis of the main body 100 . It should be understood that the circular gap in the middle of the raised portion 200 is designed to facilitate the crankshaft 300 passing through the muffler without interference. In one embodiment, when the crankshaft 300 of the compressor does not need to be arranged at the same position as the muffler, the muffler The raised portion 200 can also be a cylinder. It should be understood that the above-mentioned concepts of circular cylinder and cylinder are not concepts in the context of geometry, such as circular frus...

Embodiment 3

[0048] This embodiment provides a compressor, including a muffler, an oil storage part, and a refrigerant discharge chamber. For specific structural details of the muffler, reference may be made to Embodiment 1 or Embodiment 2.

[0049] In a preferred embodiment, the muffler is arranged between the oil storage part 400 and the refrigerant exhaust chamber 500, and the contact area between the muffler and the oil storage part 400 is the same as that of the oil storage part 400. Volume ratio greater than or equal to 15mm 2 / ml. The inventor first carried out data statistics on the operating conditions of the existing compressors, obtained the common temperature of the refrigerant exhaust chamber 500 at work, and then calculated the different volumes of the oil storage part 400 and the silencer through the thermodynamic simulation software. The final temperature of the oil after heat exchange under surface area conditions. Through the analysis and summary of the calculation resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com