Wear-resistant shaft sleeve structure for sealing speed reducer

A technology for sealing and reducer, applied in the direction of bearing components, shafts and bearings, transmission parts, etc., can solve the problems of pollution, inability to deal with seal failure online, contact wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

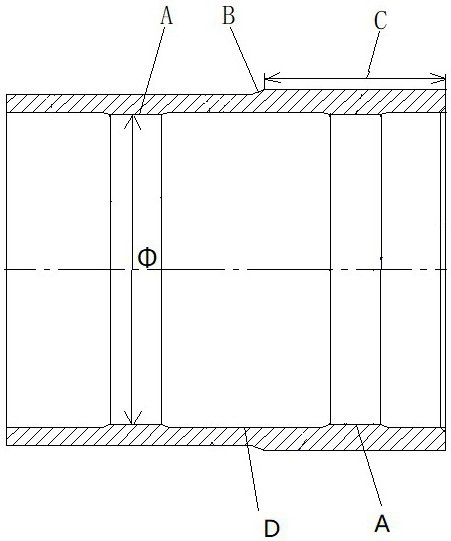

[0008] A wear-resistant ax sleeve for a reductionler seal, such as figure 1 As shown, including a bushing body, the outer peripheral diameter of the outer peripheral edge of the outer peripheral edge of the shaft body is 4 mm than the outer peripheral edge of the right side of the shaft body, and the outer peripheral length C of the right side of the shaft body is 70-90 mm, the right The quenching depth of the side is 1-1.5mm; the middle of the outer peripheral edge of the shaft body has an annular shoulder transition surface B, the left side of the shaft body, and the left side of the shaft body have a shrinking hole A, which two shrinkage holes. The pore size is φ120 mm, the upper deviation + 0.055mm, the lower deviation + 0.025mm is an overference fitting section, the width of the two shrinkles is 20mm, and the bushing between the two shrinkles has a depth of 0.5. The annular machining of the mm D, which has a width of 70-90 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com