Muffle furnace for laboratory

A laboratory muffle furnace technology, applied in muffle furnaces, furnaces, cooking furnaces, etc., can solve the problems of experimental work impact, knocking over, and impact on effectiveness, and achieve safe and reliable use, simple and fast operation, and excellent structure novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

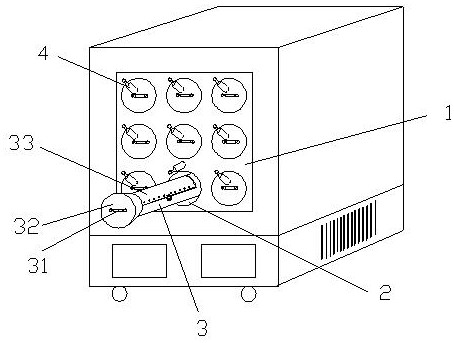

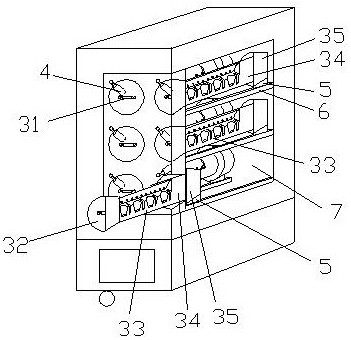

[0024] Such as Figure 1-4 As shown, this embodiment provides a muffle furnace for laboratory use, including a furnace 7 and a panel furnace wall 1 located outside the furnace 7. It is characterized in that at least two furnace compartments communicating with each other are provided in the furnace 7 , the furnace cabin includes a furnace hatch 2, the furnace hatch 2 is located on the panel furnace wall 1, and each furnace cabin is provided with a movable furnace groove 3. Each mobile furnace tank 3 can be heated at the same time and taken out in different time periods to meet different needs.

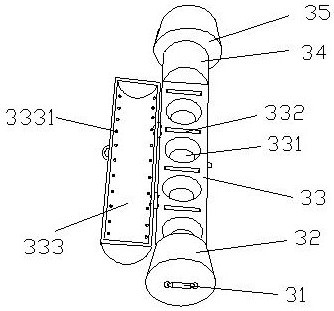

[0025] The mobile furnace tank 3 includes a first round platform 32, a crucible carrier boat 33, a solid cylinder 34 and a second round platform 35 from outside to ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com