Automatic calibrating device and method for high-precision flow nozzle

A flow nozzle and verification device technology, which is applied in the direction of testing/calibrating volume flow, etc., can solve problems such as complex operation, poor accuracy of verification results, and large amount of manual calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

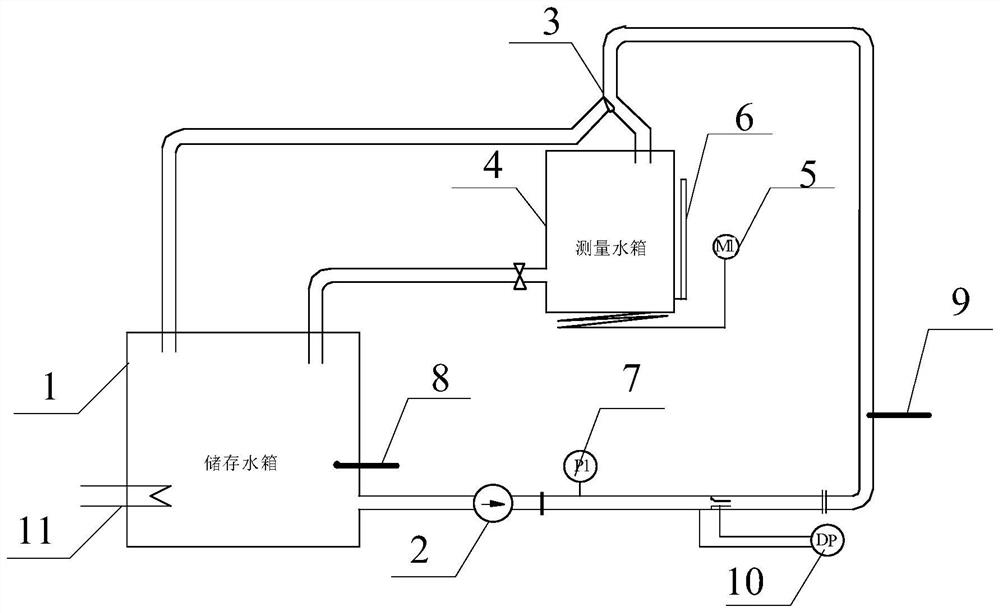

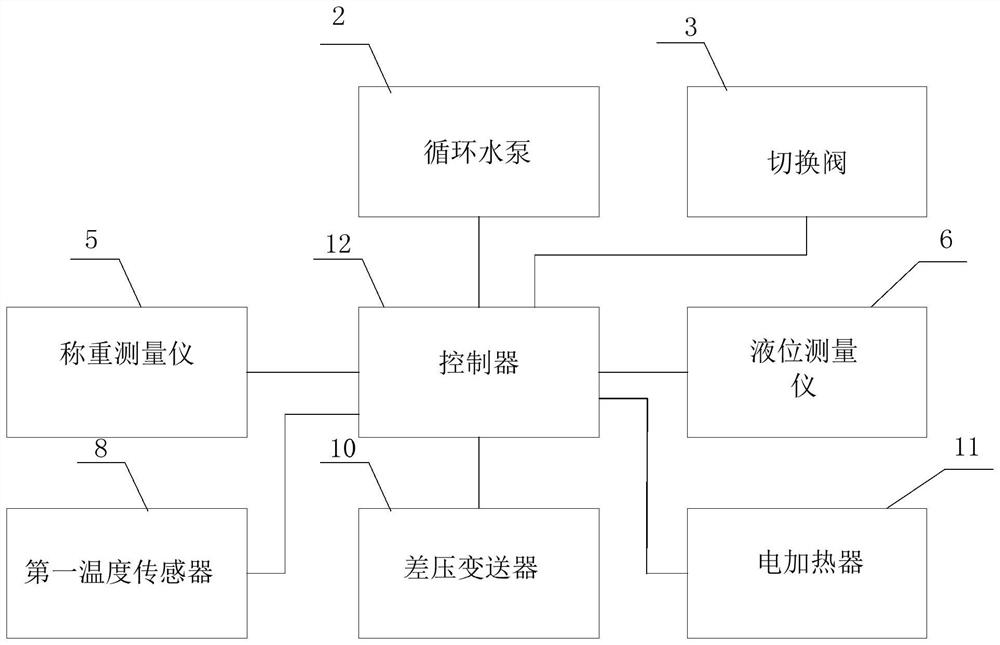

[0041] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the automatic verification device of the high-precision flow nozzle described in this embodiment includes a storage water tank 1, a circulating water pump 2, a switching valve 3, a measuring water tank 4, a weighing measuring instrument 5, a liquid level measuring instrument 6, and a controller 12. The first temperature sensor 8, the differential pressure transmitter 10, the electric heater 11, the flow nozzle to be verified and the connecting pipe;

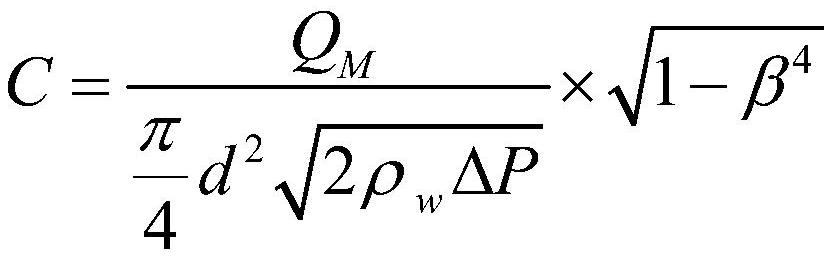

[0042] The side wall of the storage water tank 1 is provided with a water outlet, and the water outlet of the storage water tank 1 is connected to the water inlet of the high-precision flow nozzle through a connecting pipe, and the positive pressure end of the differential pressure transmitter 10 is set at the water inlet of the high-precision flow nozzle. On the side, the negative pressure end of the differential pressure transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com