Online graphite boat warped piece detection device and detection method

A detection device, graphite boat technology, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of damage and pollution of graphite boats and silicon wafers, poor reliability and timeliness of manual detection, and affect the beat, etc., to achieve Improve the working rhythm, high degree of automation, and high detection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

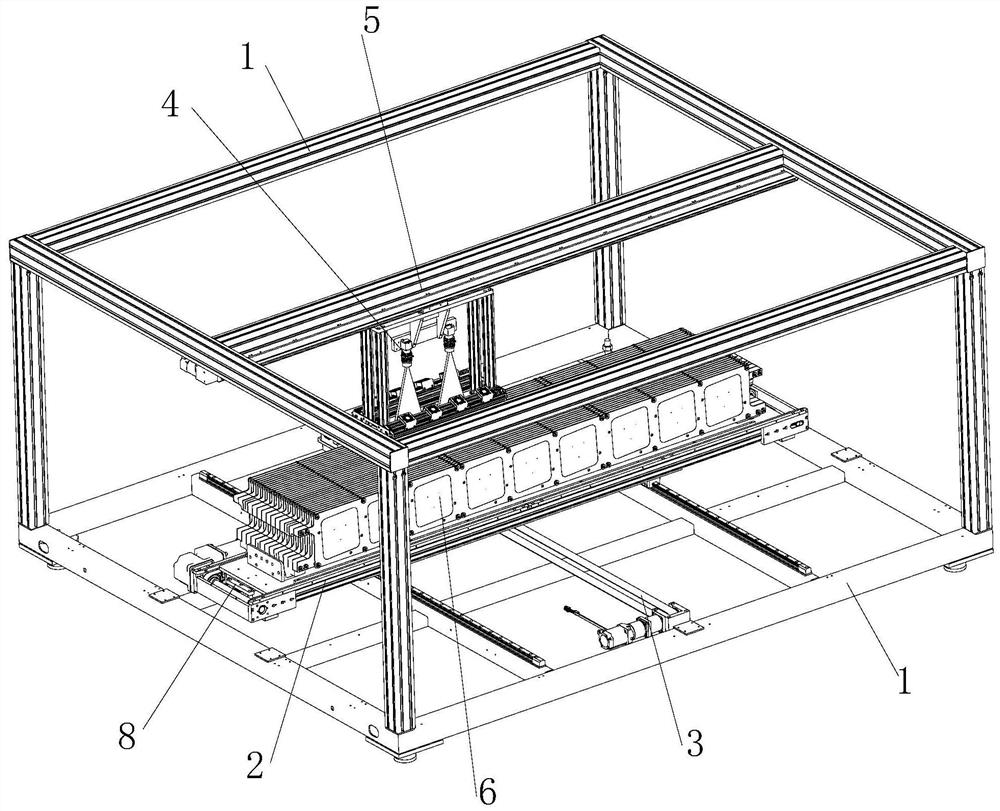

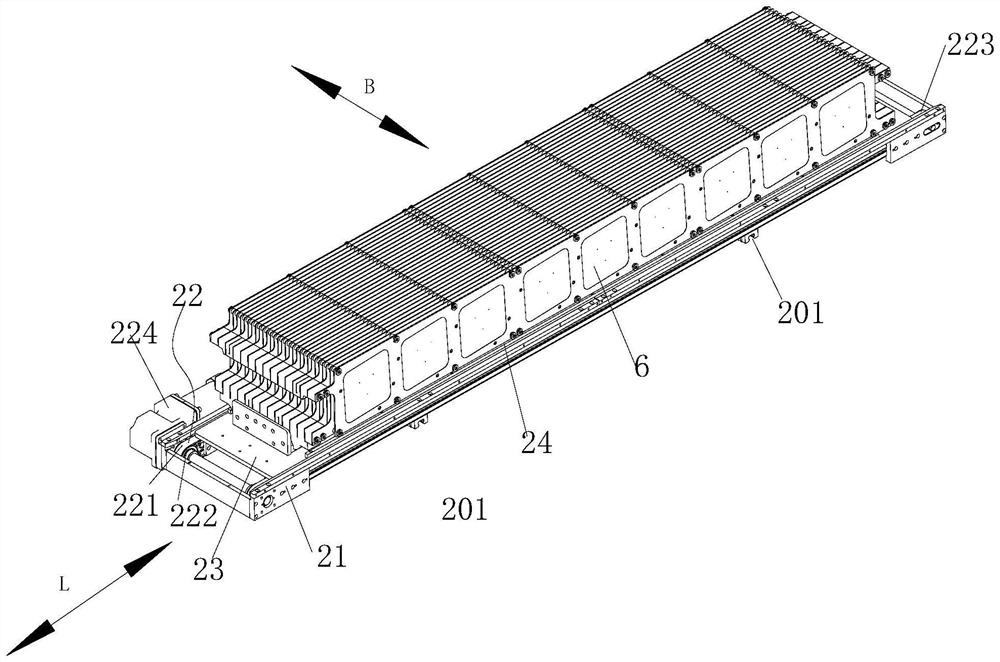

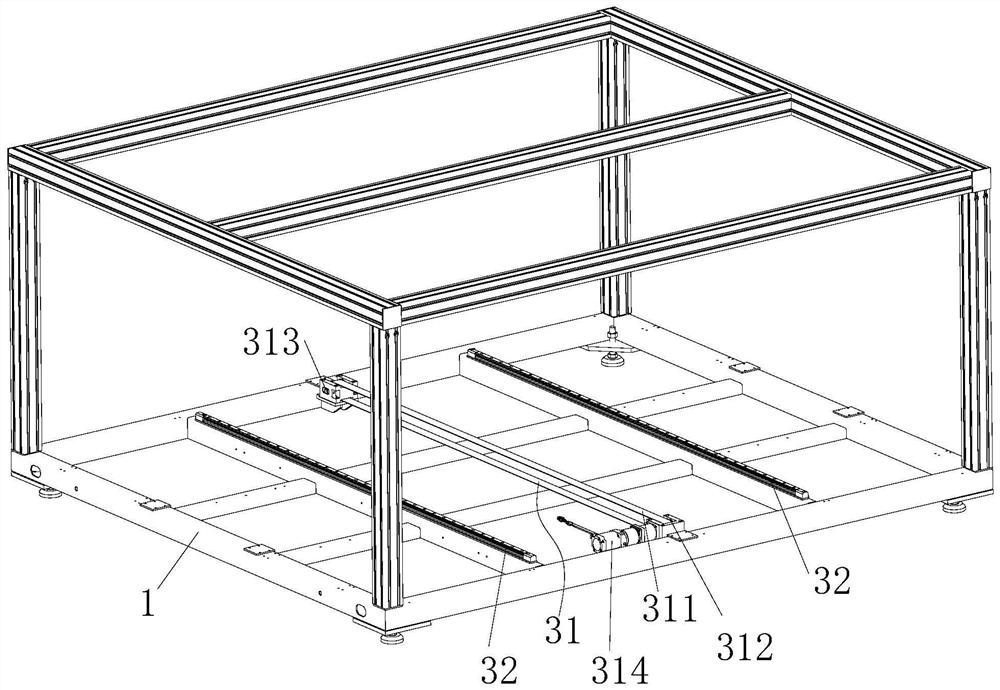

[0043] like Figure 1 to Figure 5 As shown, the online graphite boat warping sheet detection device of the present embodiment includes a frame 1, a graphite boat longitudinal transmission mechanism 2, a graphite boat transverse transmission mechanism 3, a detection element 4 and a detection longitudinal movement mechanism 5, and a graphite boat transverse transmission mechanism 3 Located at the bottom of the frame 1, the graphite boat longitudinal transmission mechanism 2 is arranged on the graphite boat horizontal transmission mechanism 3, the graphite boat longitudinal transmission mechanism 2 is used to drive the graphite boat 6 to move longitudinally, and the graphite boat horizontal transmission mechanism 3 is used to drive the graphite boat The longitudinal transmission mechanism 2 moves laterally, and the detection longitudinal movement mechanism 5 is arranged on the frame 1 and above the graphite boat transverse transmission mechanism 3, and the detection longitudinal m...

Embodiment 2

[0063] like Image 6 As shown, the online graphite boat warped sheet detection device of the present embodiment only differs from Embodiment 1 in that:

[0064] In this embodiment, two graphite boat vertical transmission mechanisms 2 are provided, and the two graphite boat vertical transmission mechanisms 2 are respectively arranged on the graphite boat horizontal transmission mechanism 3 so as to be movable laterally. For ease of distinction, the two graphite boat longitudinal transport mechanisms 2 are marked as 2a and 2b respectively, and the graphite boats 6 on the two graphite boat longitudinal transport mechanisms 2 are marked as 6a and 6b respectively. All the other structures are consistent with Example 1.

[0065] The detection method of the on-line graphite boat warp detection device of the present embodiment may further comprise the steps:

[0066] S1. The first graphite boat 6a output by the upstream equipment outlet is transmitted to a graphite boat longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com