Waveform generation method for electrochemical workstation

A waveform generation and waveform generator technology, which is applied in the direction of electrical digital data processing, digital function generators, instruments, etc., can solve the problems of unfavorable streamlining costs, frequency control methods that cannot achieve accurate frequency control, and consume storage space, etc., to achieve optimization Smoothness, optimize the overall workflow, reduce the effect of memory space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in connection with the specific embodiments, but the embodiments of the present invention are not limited thereto.

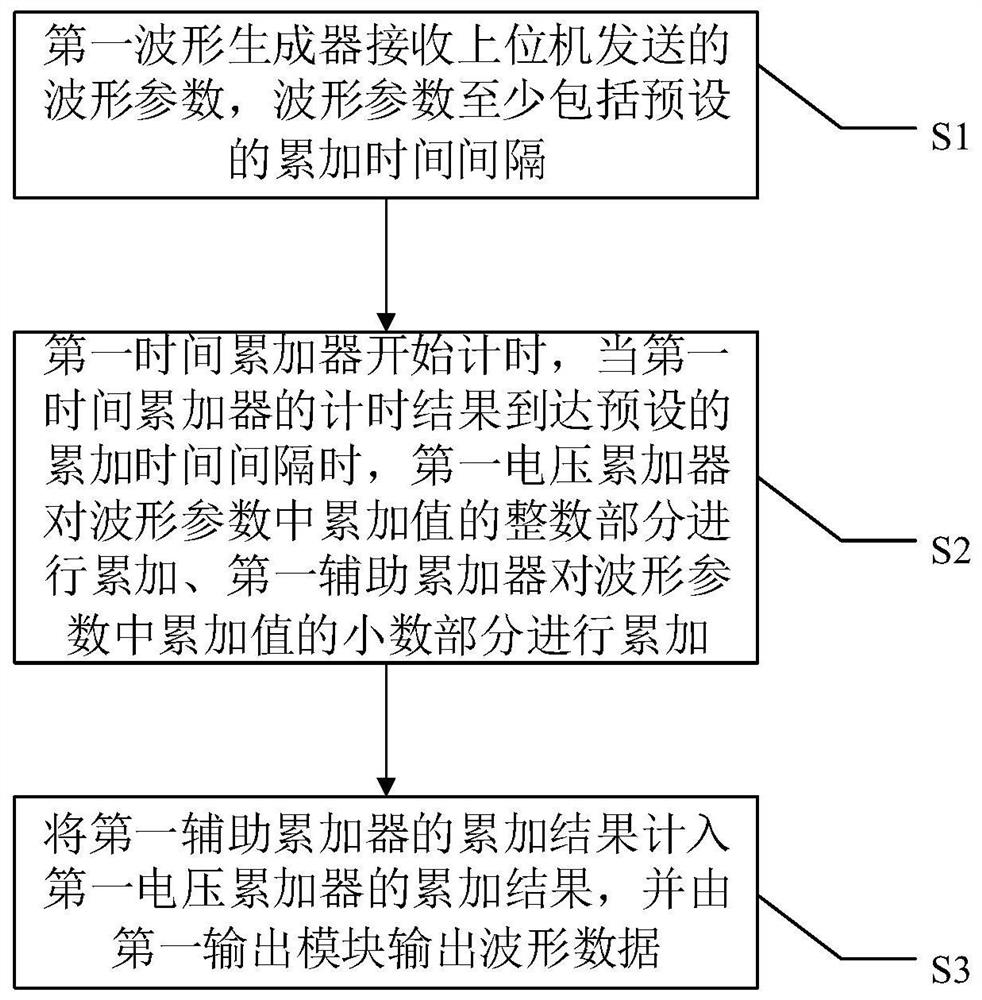

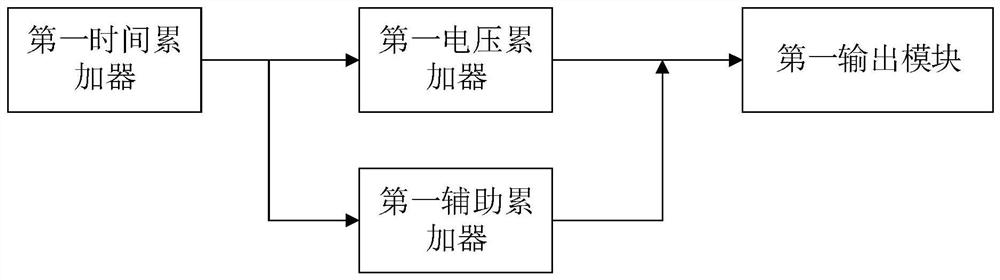

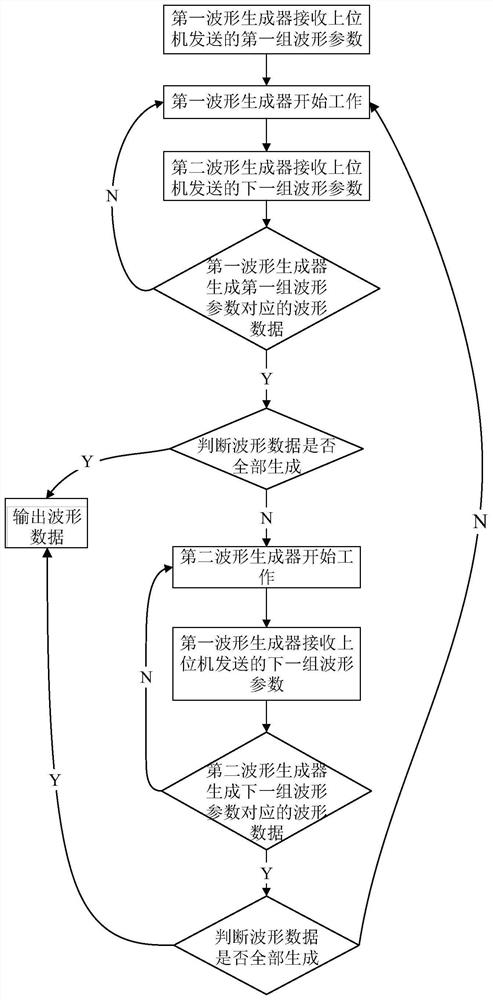

[0043] figure 1 A flow diagram of a waveform generation method for an electrochemical workstation provided in the embodiment of the present invention, figure 2 It is a block diagram of the first waveform generator provided by the embodiment of the present invention. See Figure 1-2 The embodiment of the present invention provides a waveform generation method for an electrochemical workstation, and an electrochemical work station comprises a first waveform generator, and the first waveform generator includes a first time accumulator, a first voltage accumulator, and a first auxiliary accumulation. And the first output module;

[0044] Waveform generation methods include:

[0045] S1, the first waveform generator receives the waveform parameters transmitted by the host computer, and the waveform parameter includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com