Rod bending device for orthopedic spinal operation connecting rod and forming method

A technology of connecting rods and bending rods, applied in the directions of internal bone synthesis, fixator, internal fixator, etc., can solve the problems of complicated operation, damage to the spinal cord and nerve of patients, time-consuming and laborious, and achieve the effect of simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

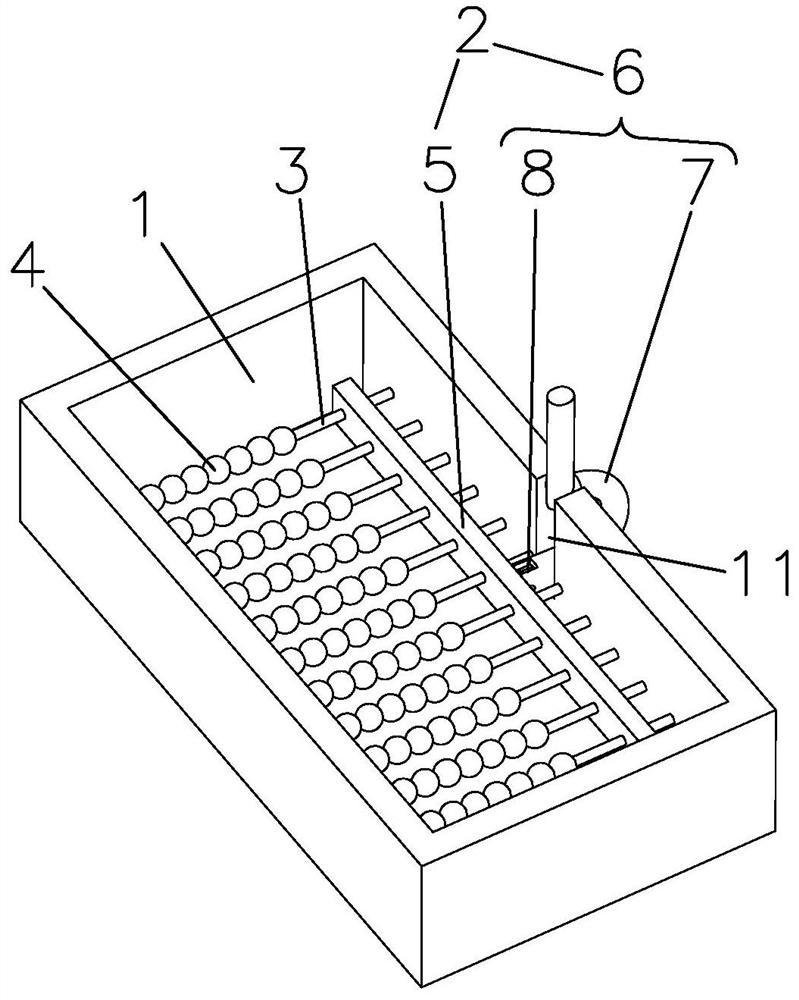

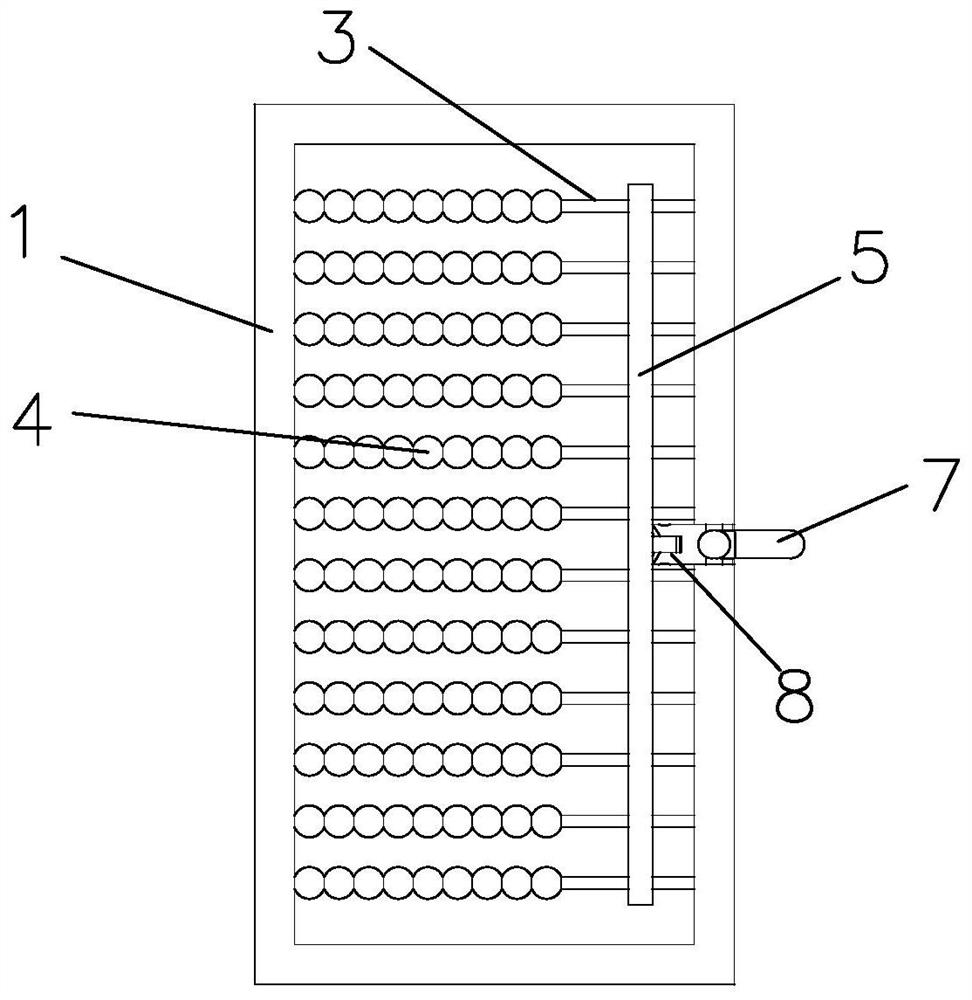

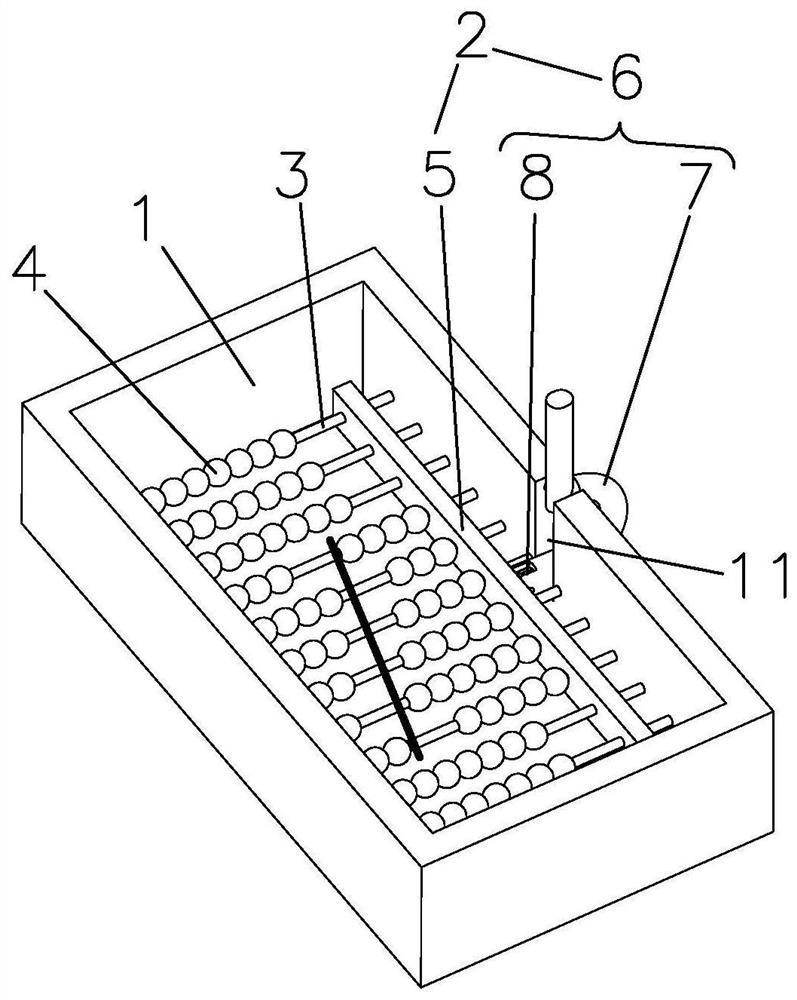

[0033] refer to figure 1 , figure 2 A rod bender for connecting rods in orthopedic spinal surgery, comprising a rigid frame bearing tray 1, a bending assembly 2, a sliding rod 3 and a sliding member 4, the rigid frame loading tray 1 has a rectangular metal frame, and the bending assembly 2 It includes a pressing plate 5 vertically arranged with the sliding rod 3 and a driving mechanism 6 that drives the pressing plate 5 to slide toward the sliding part 4; the sliding rod 3 is a metal rod with a smooth surface and has a plurality of parallel erected in the rigid frame carrying plate 1 to form a fence According to the same structure, each sliding rod 3 is pierced with a set of sliding parts 4, and when the volume of the sliding parts 4 is smaller, the more and more densely the sliding rods 3 are arranged, the higher the accuracy of the bending rod.

[0034] Normally, the sliders 4 are arranged on the same side of the rigid frame carrying plate 1 to form an array, and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com