O-shaped rubber ring assembling equipment and assembling method thereof

A technology for assembling equipment and rubber rings, which is applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of low assembly efficiency of rubber rings, and achieve the effect of efficient, accurate press fitting and volume reduction in the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

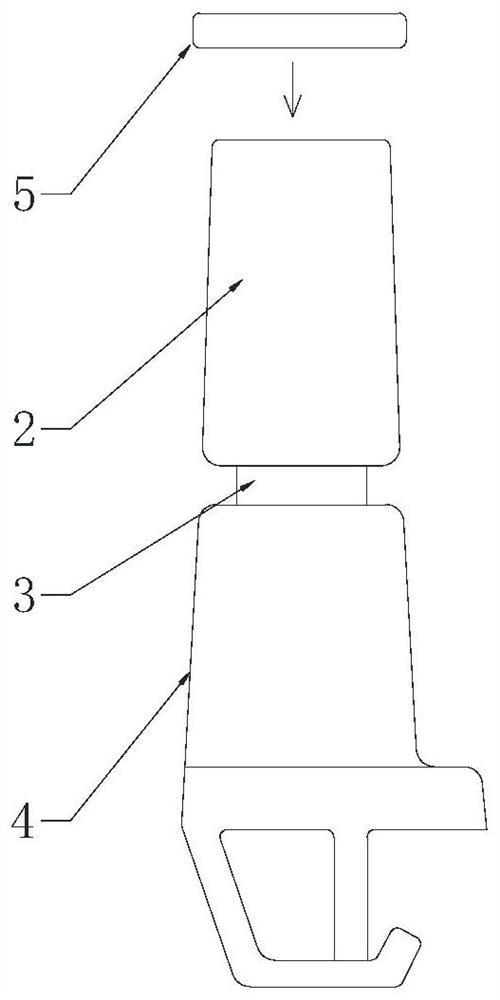

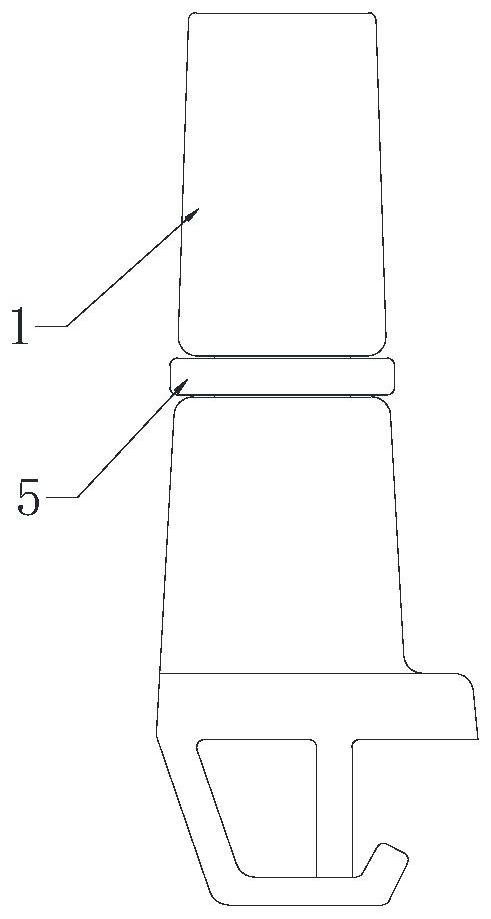

[0043] Such as Figure 1 to Figure 7 As shown, an O-shaped rubber ring assembly equipment is used to assemble the rubber ring 5 on the tubular part 1, such as infusion joints, but not limited to infusion joints, and can also be other products with similar structures, please refer to figure 1 and figure 2 , the tubular part 1 includes an upper tube body 2, a limiting part 3 and a lower clamp seat 4 integrally formed from top to bottom in sequence, the upper tube body 2 is a tapered cylinder gradually expanding from top to bottom, and the limiting part 3 is The ring shape shrinks inwardly from the bottom of the upper tube body 2 , and the rubber ring 5 needs to be assembled on the stopper 3 .

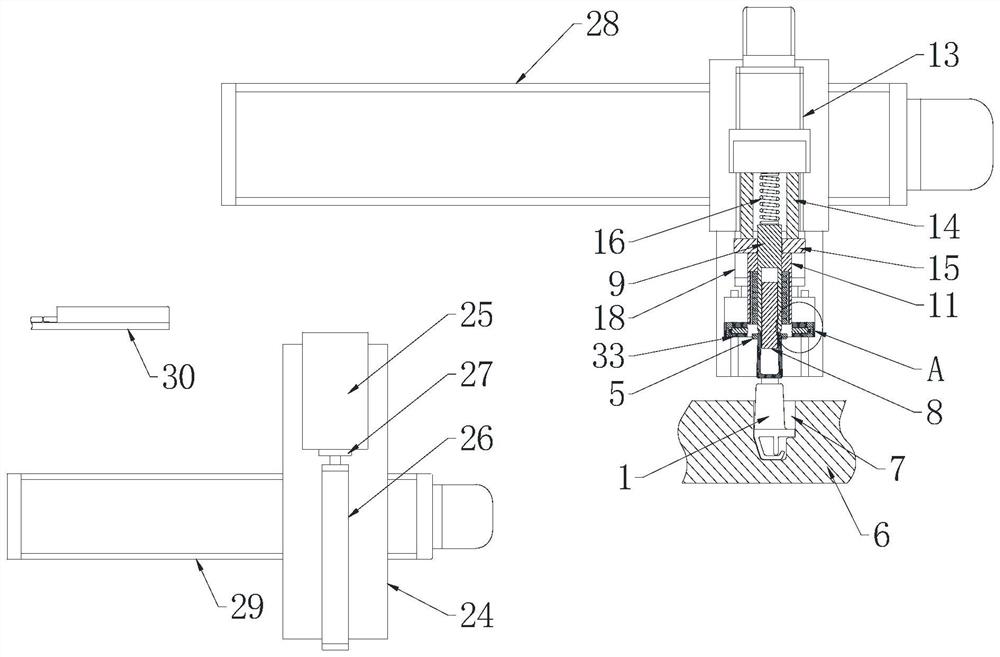

[0044] Such as image 3 As shown, the O-ring rubber ring assembly equipment includes: a conveying mechanism and a press-fitting mechanism.

[0045] The conveying mechanism 6 is used for intermittently conveying the tubular parts to the press-fitting mechanism. A plurality of positioni...

Embodiment 2

[0064] In this embodiment, on the basis of Embodiment 1, a feeding mechanism is also provided for automatically supplying the rubber ring 5 to the hair ring body 11 . Such as Figure 6 and Figure 7 As shown, the feeding mechanism includes a support plate 24 vertically installed on the frame, on which the feed bin 25 and the third lift driver 26 are fixedly installed, and the third lift driver 26 can be selected from a pen-shaped cylinder or other realizable Drives for linear motion. The storehouse body of feed bin 25 is all exposed up and down, and a row of rubber rings 5 is accommodated in the storehouse body along the vertical direction, and the third lift driver 26 is positioned at the below of feed bin 25, and top block 27 is installed on its piston rod, and the diameter of top block 27 Slightly less than the outer diameter of the rubber ring 5, to push up the rubber ring in the warehouse body until it is tightly placed on the slide pipe 9 directly above it. Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com