Forming process for composite explosive

A molding process and explosive technology, applied in the field of explosives and pyrotechnics, can solve the problem of inability to achieve orderly assembly of millimeter-scale explosive component particles, and achieve the effect of orderly assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

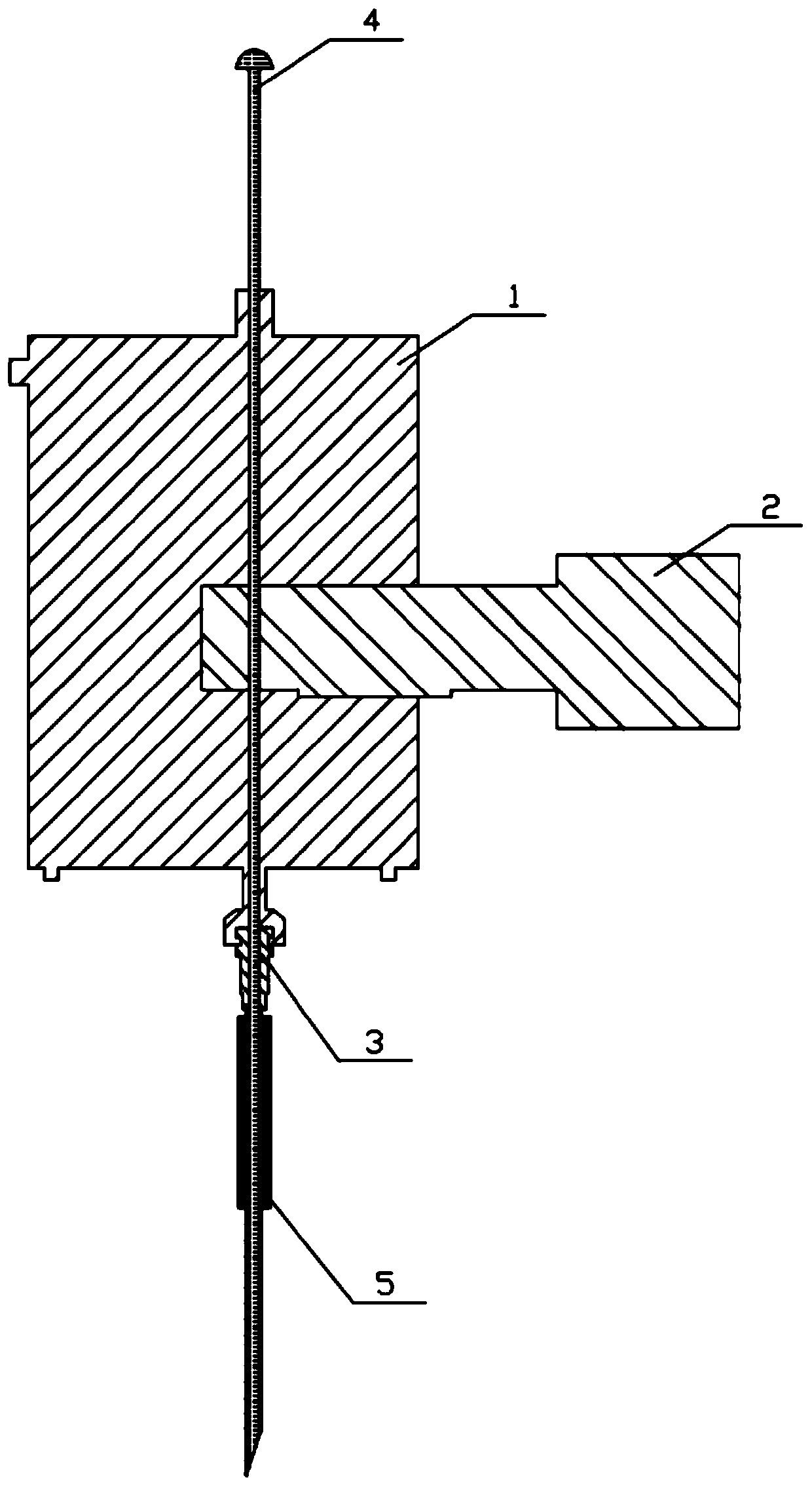

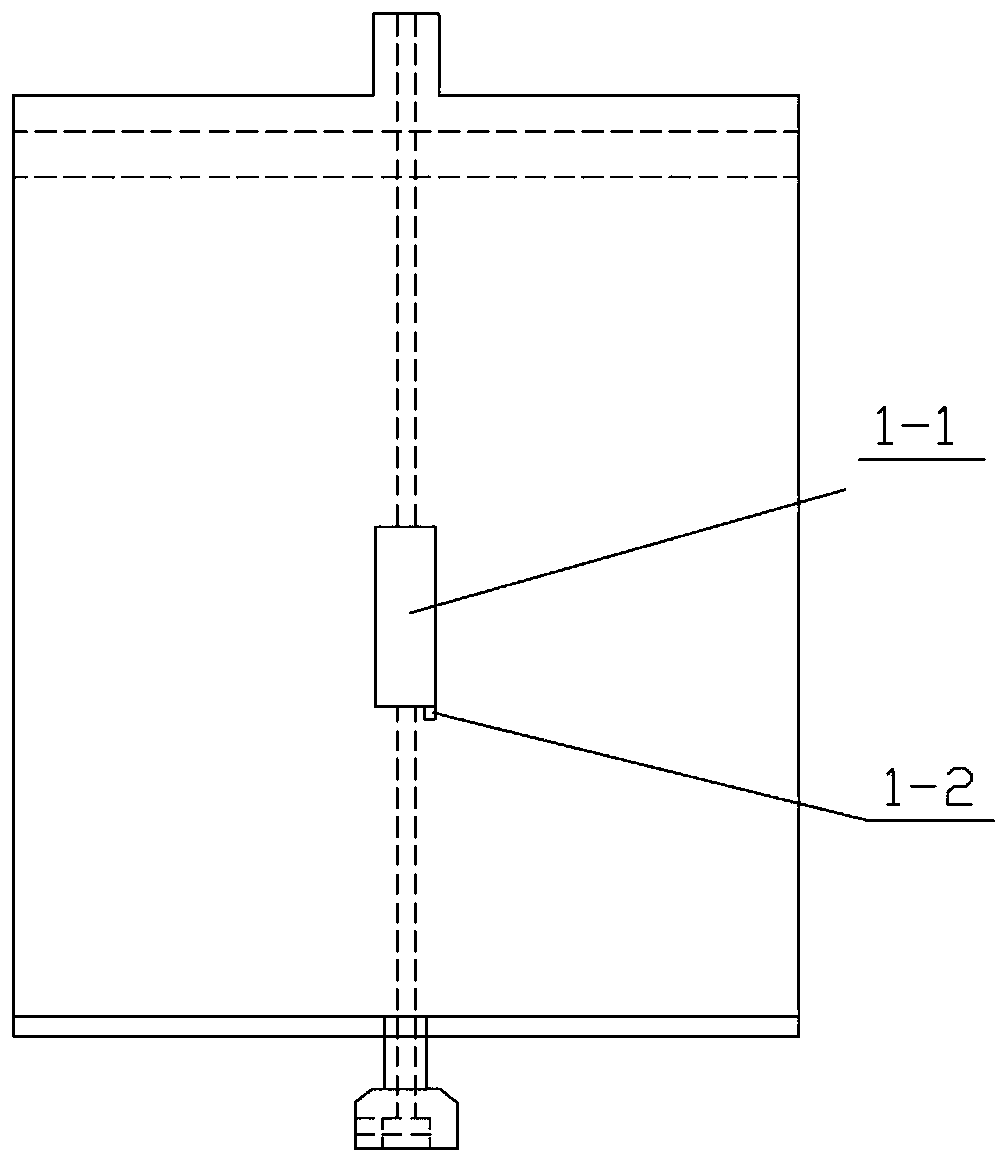

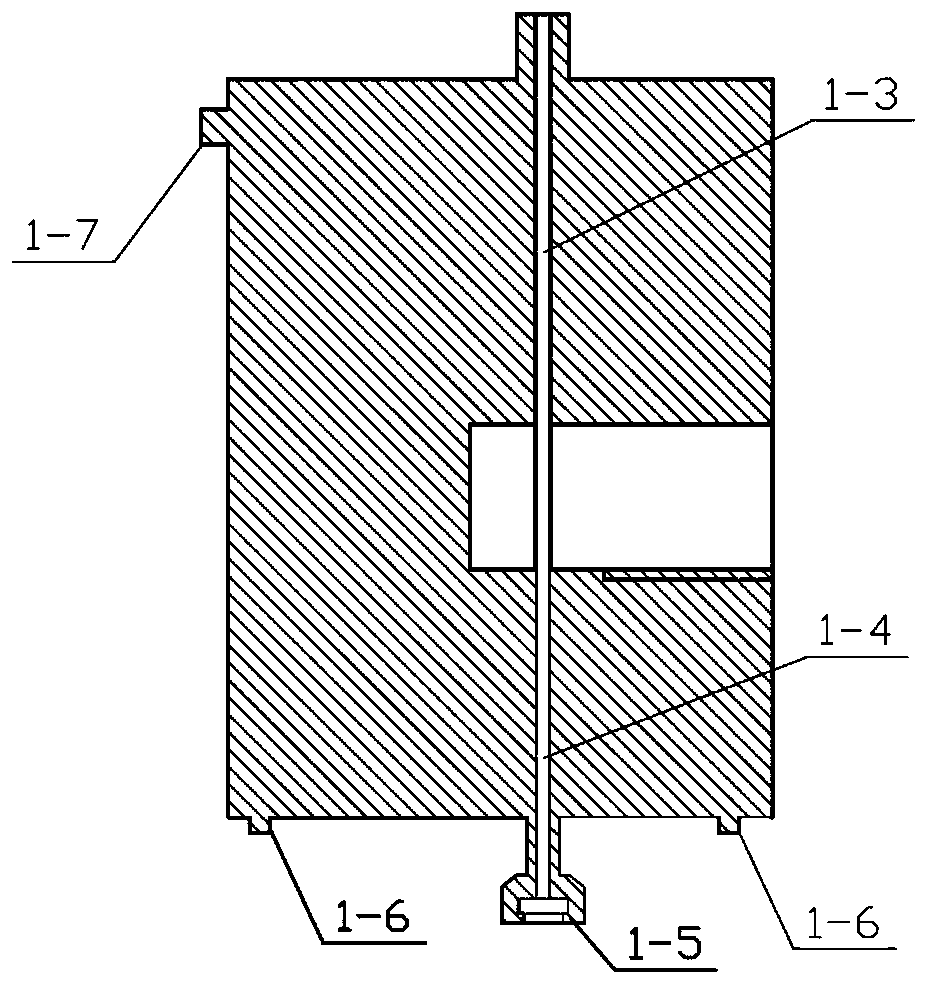

Image

Examples

Embodiment 1

[0059] Embodiment 1 of the present invention is to adopt a kind of composite explosive molding process, the highly active explosive particles ALH 3 Particles and Al particles are injected into the HMX-based cast explosive at intervals. The action process of the present invention will be described below according to the preferred embodiments of the present invention.

[0060] Step 1, determine the implantation time:

[0061] (1) Matrix formula: HMX has a solid content of 86%, the prepolymer is hydroxyl-terminated polybutadiene, dioctyl adipate, the curing agent is 2,4-toluene diisocyanate, and the combination of prepolymer and curing agent The ratio is measured as 1 according to the curing parameter, and the catalyst is triphenylbismuth (the added amount is 0.01% of the total amount).

[0062] (2) Measure the Fourier transform infrared spectrograms of the slurry with different curing times, and obtain the corresponding curing times of 75% and 85% of the conversion rate as 7.5...

Embodiment 2

[0072] Example 2 of the present invention adopts a composite explosive molding process to inject high-activity explosive particles AL particles into HMX-based cast explosives. The action process of the present invention will be described below according to the preferred embodiments of the present invention.

[0073] Step 1, determine the implantation time: refer to Example 1;

[0074] Step 2, preparation of implanted particles: AL particles are pressed by molding powder, the formula is 95% AL / 5% paraffin, and the modeling powder is prepared by water suspension method; the particles are pressed on a press to form particles with a diameter of 0.7 mm and a length of 1 mm;

[0075] Step 3, preparing the matrix: carry out with reference to Example 1;

[0076]Step 4: After adding the curing agent in step 3 for 24 hours, cool the cast explosive matrix to room temperature, and measure the Shore hardness of 18HA; put the cast explosive matrix in a vacuum box, and implant Al particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com