Lucigen cation and brucite composite luminescence film and preparation method thereof

A technology of luminescent film and hydrotalcite, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limiting the development of hydrotalcite layered materials, reduce fluorescence quenching, realize immobilization and thin film, and realize orientation The effect of alignment and even dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

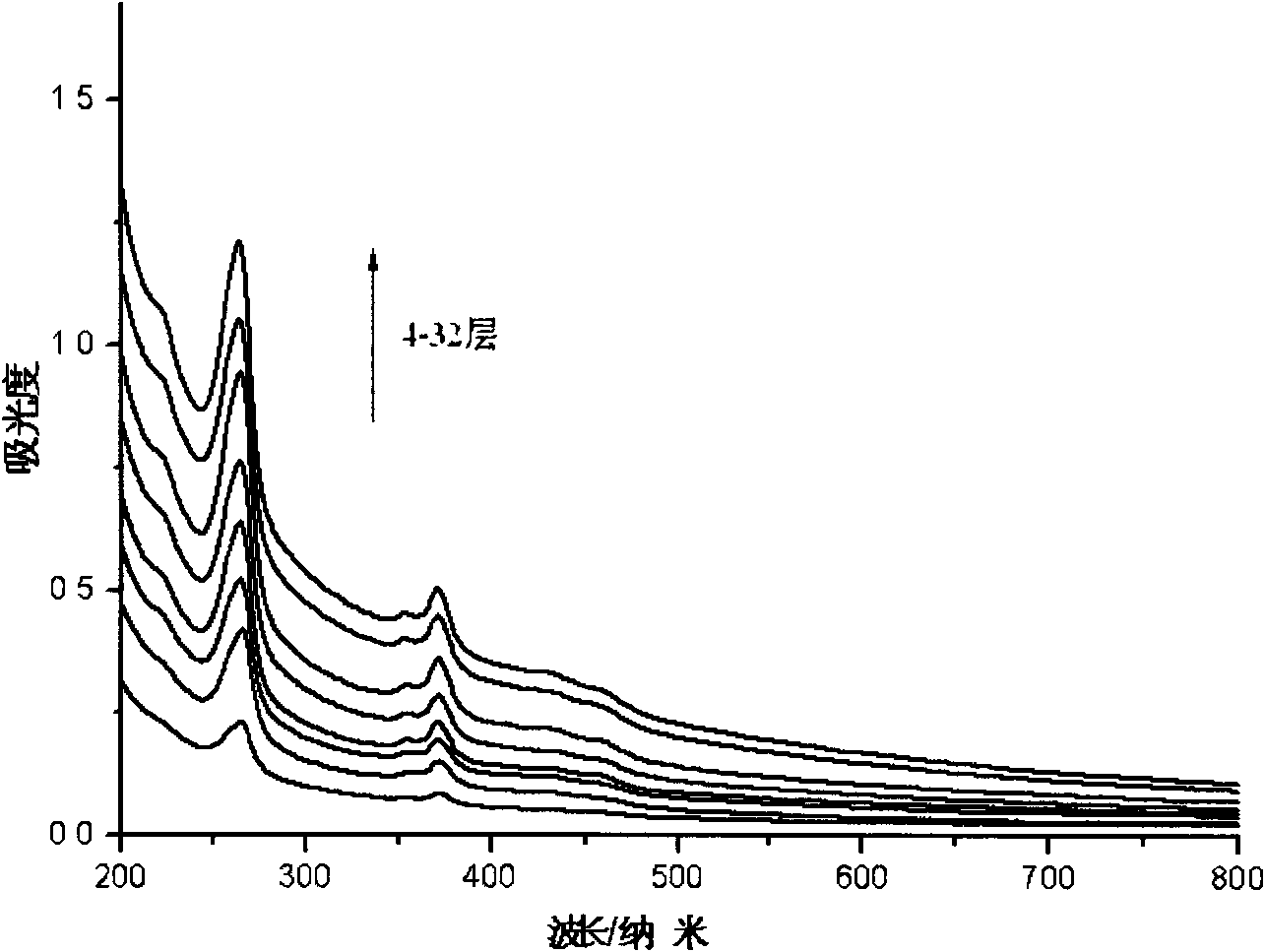

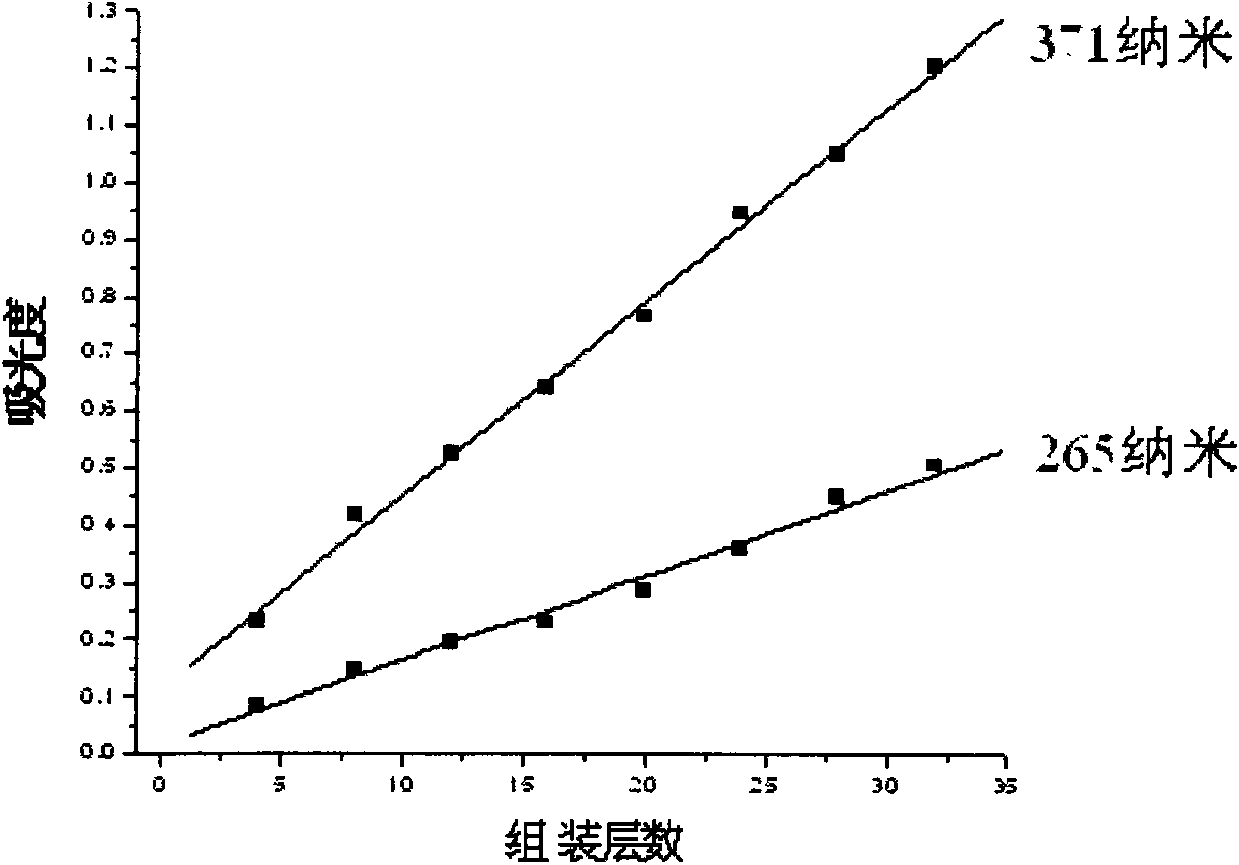

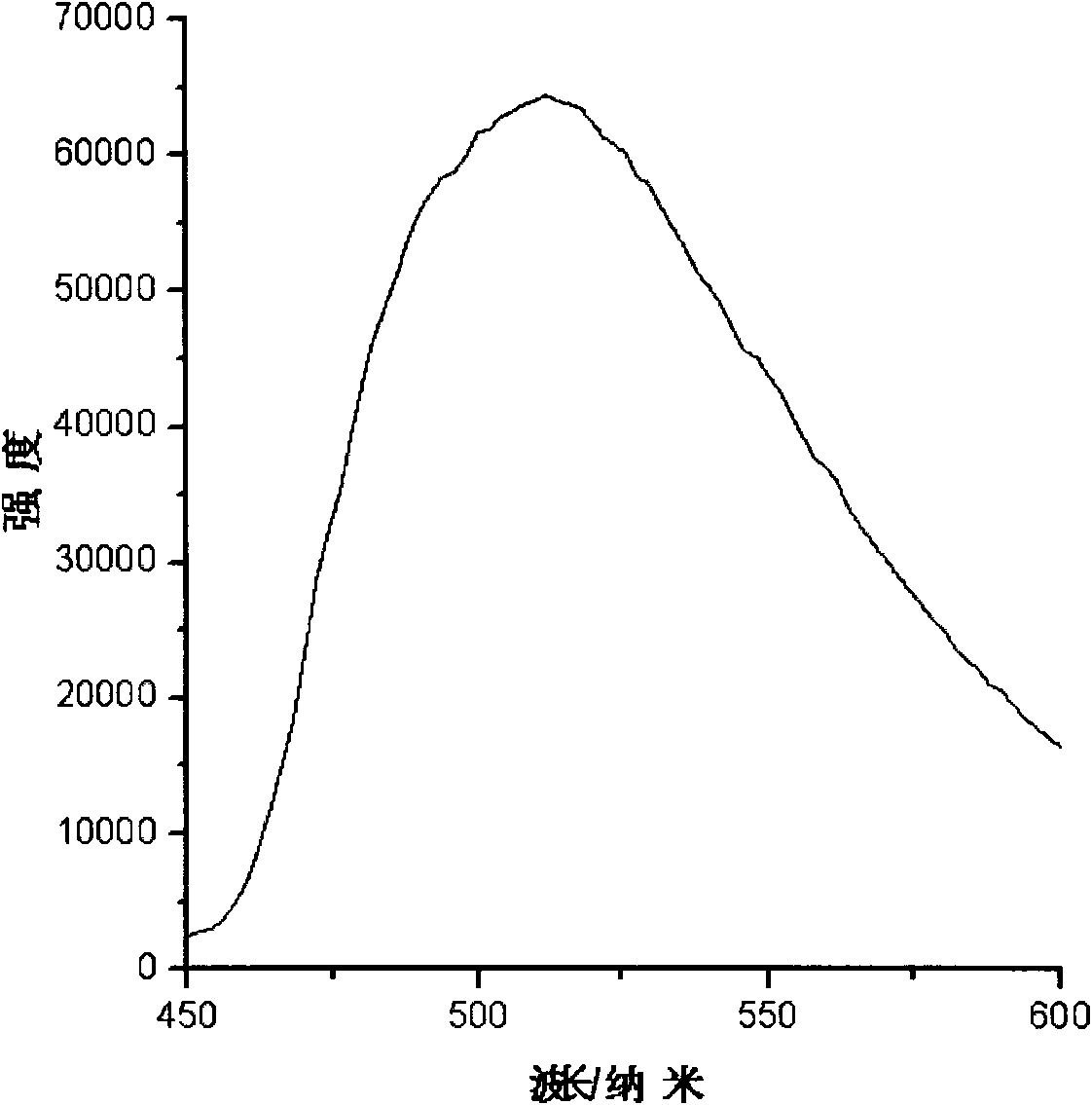

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of hydrotalcite precursor with nitrate between layers by ion exchange method:

[0029] a. Add 0.010mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.005 mol of solid Al(NO 3 ) 3 9H 2 O and 0.06mol urea were dissolved in 70mL of deionized water, and crystallized in a 90ml polytetrafluoroethylene pressure reaction vessel at 100°C for 24 hours, then centrifugally washed with deionized water until the pH was about 7,70 ℃ drying for 12 hours to obtain carbonate hydrotalcite;

[0030] b. Take 0.3g of the above-mentioned carbonate hydrotalcite and solid NaNO 3 63.75g dissolved in 300mL to remove CO 2 After uniformly dispersed in deionized water, add 0.07mL of concentrated nitric acid and stir at 25°C under a nitrogen atmosphere to carry out ion exchange reaction for 12 hours and then use 2 The deionized hot water was centrifuged and washed to a pH of about 7, and dried at 70°C for 18 hours to obtain a magnesium-aluminum nitrate-intercalated hydrotalcite composite m...

Embodiment 2

[0037] 1. Preparation of nitrate hydrotalcite precursor by co-precipitation method:

[0038] a. Add 0.03mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.01mol of solid Al(NO 3 ) 3 9H 2 O dissolved in 50mL to remove CO 2 of deionized water;

[0039] b. Dissolve 0.06mol NaOH in 50mL to remove CO 2 of deionized water;

[0040] c. the alkali solution prepared by step b is placed in a four-necked bottle, 2 Under the condition of air protection, while vigorously stirring, slowly drop the salt solution prepared in step a into the four-necked bottle, and the drop is completed in about 0.5h. After the drop is completed, use 5mol / L NaOH solution to adjust its pH value to 8. React in a water bath at 60°C for 24h, remove CO with 2 The deionized hot water was centrifuged and washed to a pH of about 7, and dried at 70°C for 24 hours to obtain a magnesium-aluminum nitrate-intercalated hydrotalcite composite material;

[0041] 2. Take 0.1 g of the above-mentioned nitrate intercalated hydrota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com