Composite lighting thin film material of nucleotide and layered double hydroxide nanometer sheet and preparation method thereof

A luminescent film, hydrotalcite technology, applied in luminescent materials, biochemical equipment and methods, chemical instruments and methods, etc., to achieve the effect of simple preparation process, strong operability, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of hydrotalcite precursor with nitrate between layers by ion exchange method:

[0032] a. Add 0.020mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.01mol solid Al(NO 3 ) 3 ·9H 2 O and 0.16 mol of urea were dissolved in 70 mL of deionized water, crystallized in a 90 mL polytetrafluoroethylene pressure reaction vessel at 110°C for 24 hours, and washed with deionized water by centrifugation to a pH of about 7,60 Dry at ℃ for 12h to obtain carbonate intercalated hydrotalcite;

[0033] b. Take 1g of the above carbonate intercalation hydrotalcite and solid NaNO 3 327g dissolved in 1L in addition to CO 2 After uniformly dispersing in deionized water, stir under nitrogen atmosphere at 25℃, carry out ion exchange reaction for 24 hours, and remove CO 2 Centrifugal washing with deionized hot water to pH 7, and drying at 60°C for 18 hours to obtain a hydrotalcite precursor with nitrate between the layers;

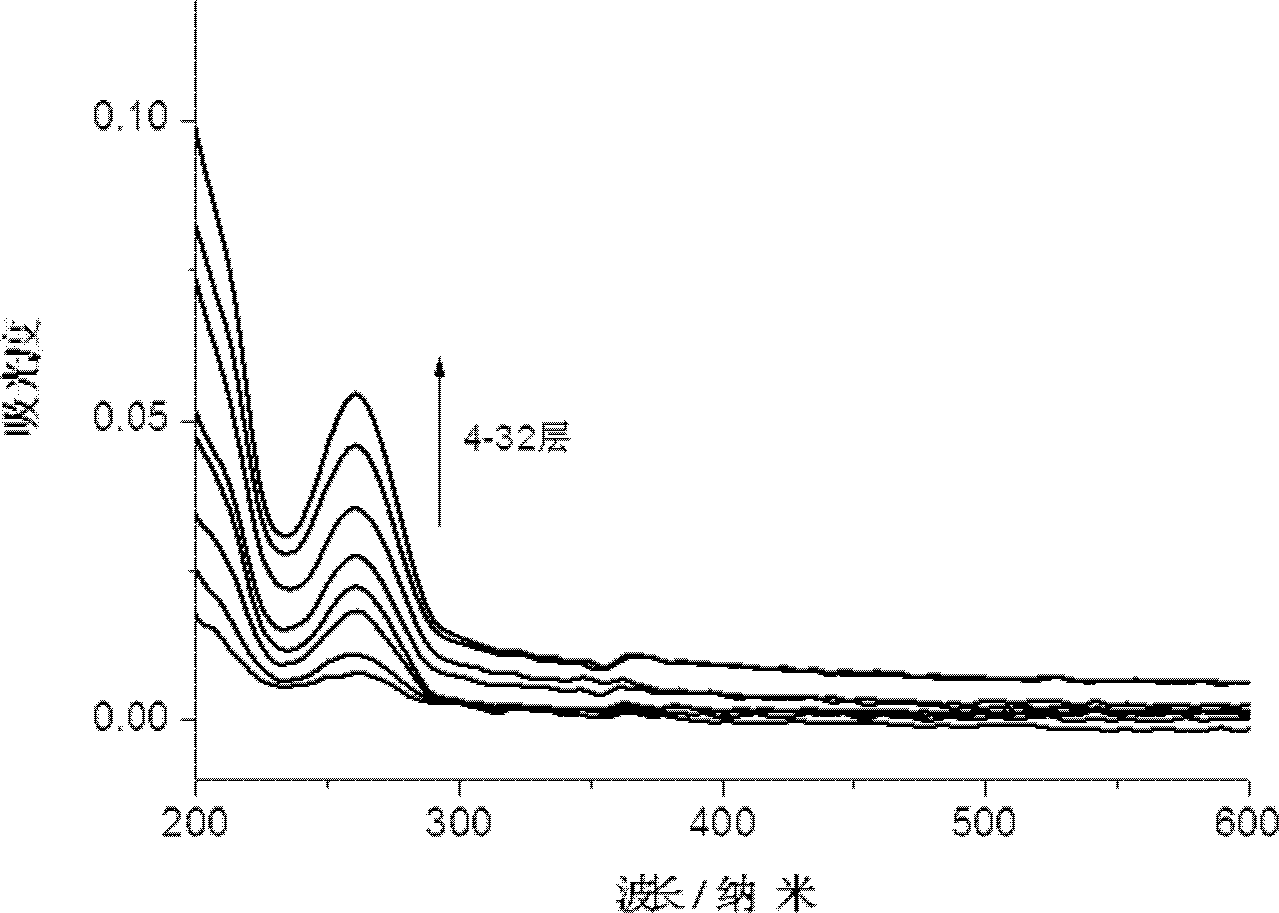

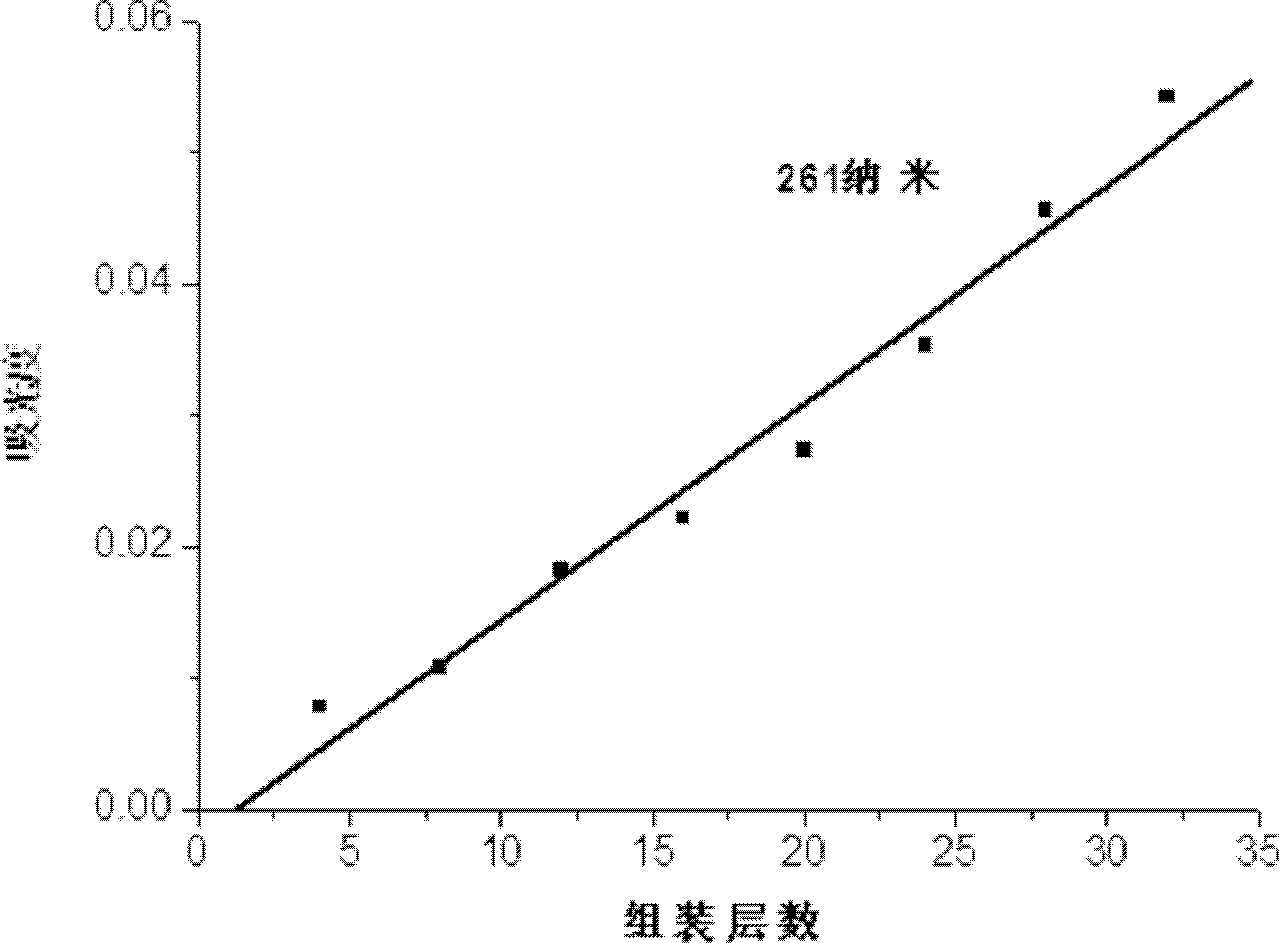

[0034] 2. Take 0.1g of the hydrotalcite precursor with nitrate between the a...

Embodiment 2

[0040] 1. Preparation of nitrate hydrotalcite precursor by co-precipitation method:

[0041] a. Add 0.02mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.01mol solid Al(NO 3 ) 3 ·9H 2 O dissolved in 50mL in addition to CO 2 Of deionized water;

[0042] b. Dissolve 0.04mol NaOH in 50mL to remove CO 2 Of deionized water;

[0043] c. Put the alkali solution prepared in step b in a four-neck bottle, 2 Under the condition of air protection, while stirring vigorously, slowly drip the salt solution prepared in step a into the four-necked flask, and drip it for about 30 minutes. After the dripping is completed, adjust the pH value to 9 with 5mol / L NaOH solution , 80℃ water bath reaction for 24h, use to remove CO 2 Centrifugal washing with deionized hot water to pH 7, and drying at 60°C for 18 hours to obtain a hydrotalcite precursor with nitrate between the layers;

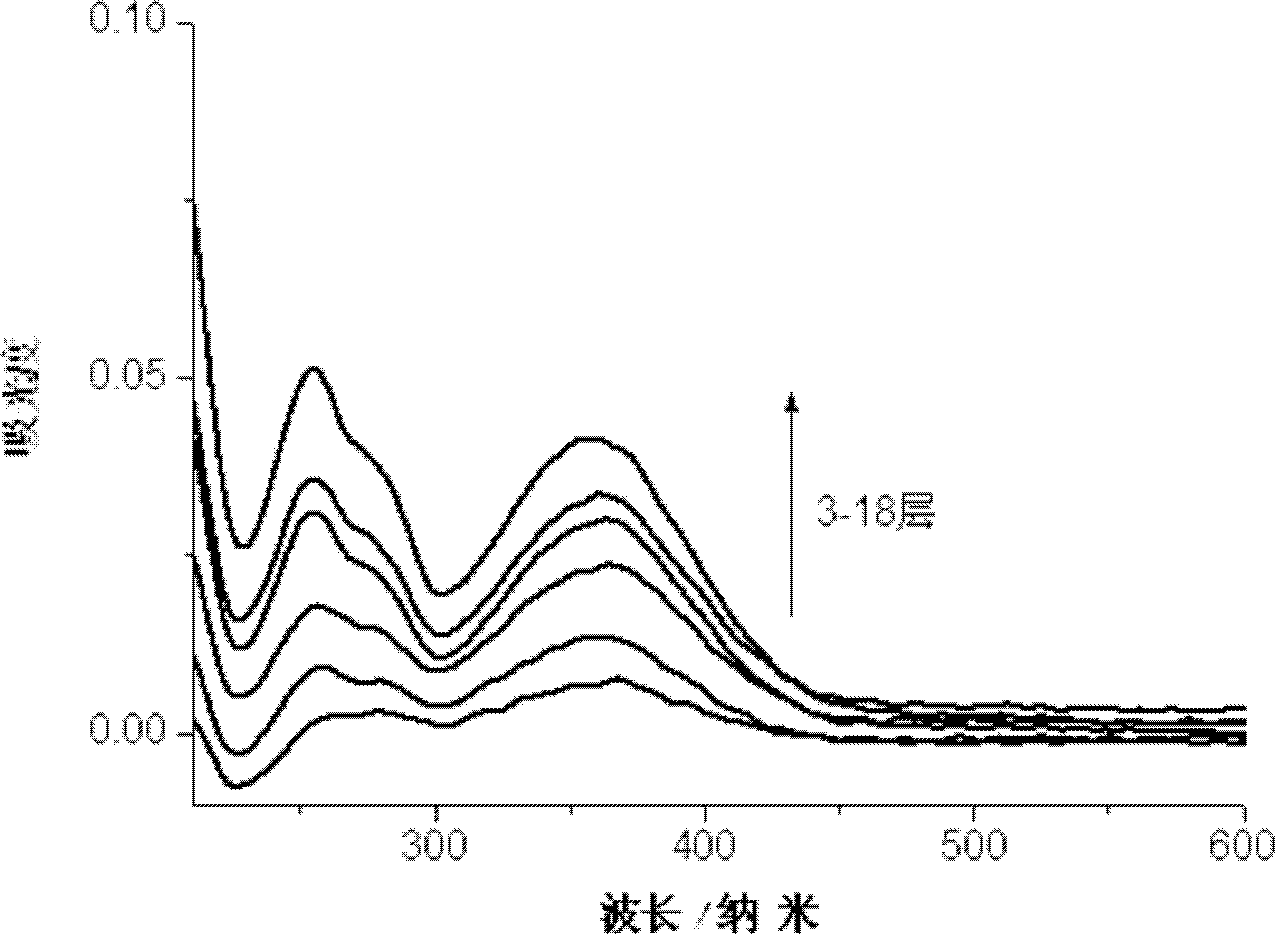

[0044] 2. Take 0.1g of the above-mentioned nitrate intercalation hydrotalcite and stir in 100ml formamide solvent for 24 hours, under nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com