Preparation equipment for energy-saving and heat-insulating concrete blocks

A concrete and block cutting technology, which is applied in the direction of clay preparation equipment, forming pressure head, manufacturing tools, etc., can solve the problems of concrete insulation, water replenishment, concrete cracks, and concrete mixing, etc., so as to increase airtightness and improve connection Tightness, improve the effect of supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

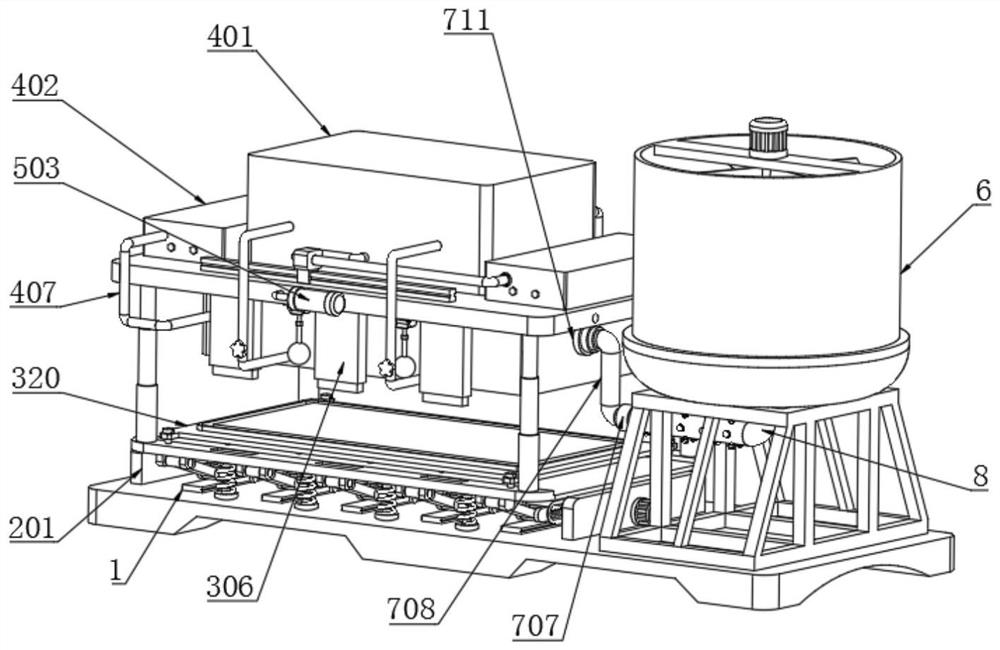

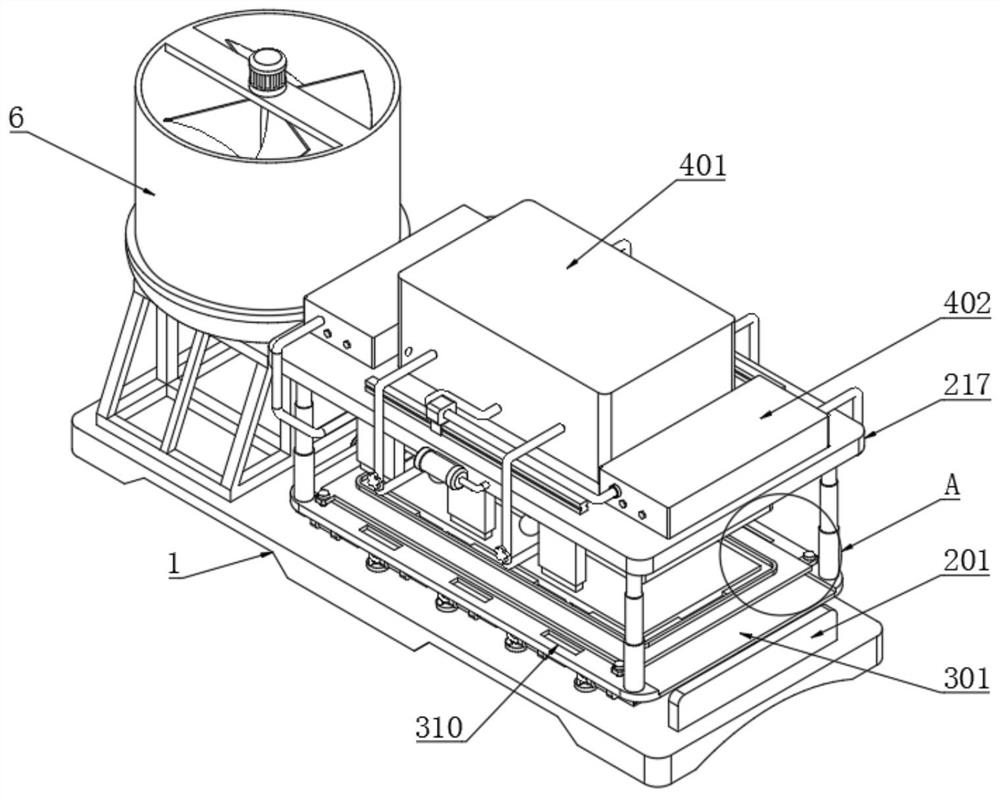

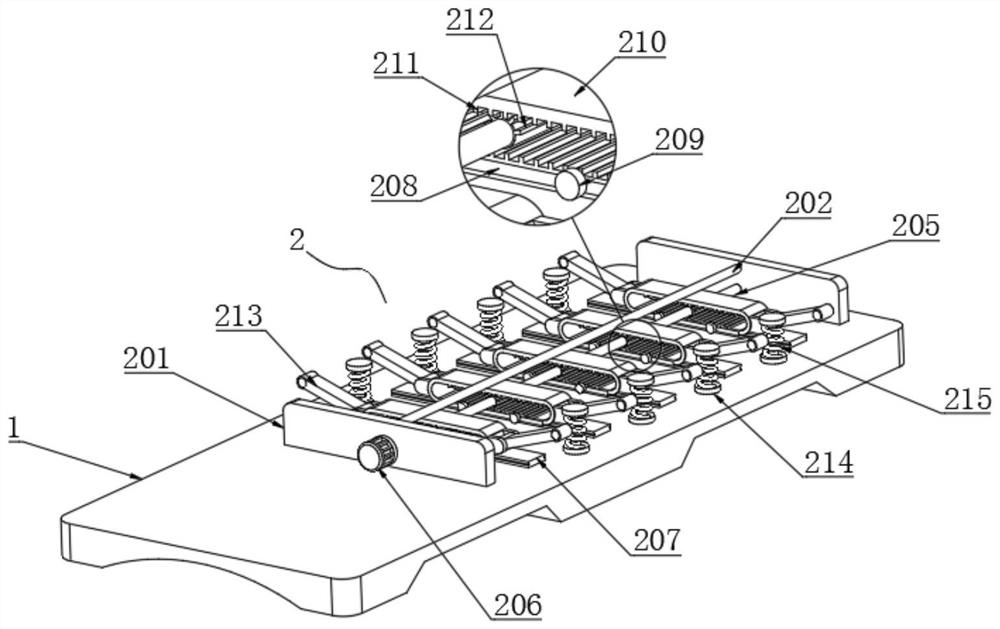

[0040] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a preparation equipment for energy-saving and heat-resisting concrete blocks, including a bottom plate 1, a stirring tank 6 is fixedly connected to the side of the top of the bottom plate 1, and a mixing tank 6 is fixedly connected to an outlet at the bottom of the mixing tank 6. The feed pipe 8, the top of the bottom plate 1 corresponding to the side of the stirring tank 6 is fixedly connected with a vibration stirring mechanism 2, the vibration stirring mechanism 2 includes a fixed plate 201, a rotating rod 202, a rotating block 203, a shaking plate 204, a rotating shaft 205, and a rotating motor 206 , slide plate 207, limit plate 208, roller 209, moving frame 210, tooth protrusion 211, gear 212, rotating plate 213, support block 214, support spring 215, electric telescopic rod 216, top plate 217 and mold 218;

[0041] The top of the bottom plate 1 is symmetrically fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com