A horizontal conveying device

A material conveying and horizontal technology, applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problem of low accuracy of material position, and achieve high manufacturing precision requirements, high work reliability, and accurate realization The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

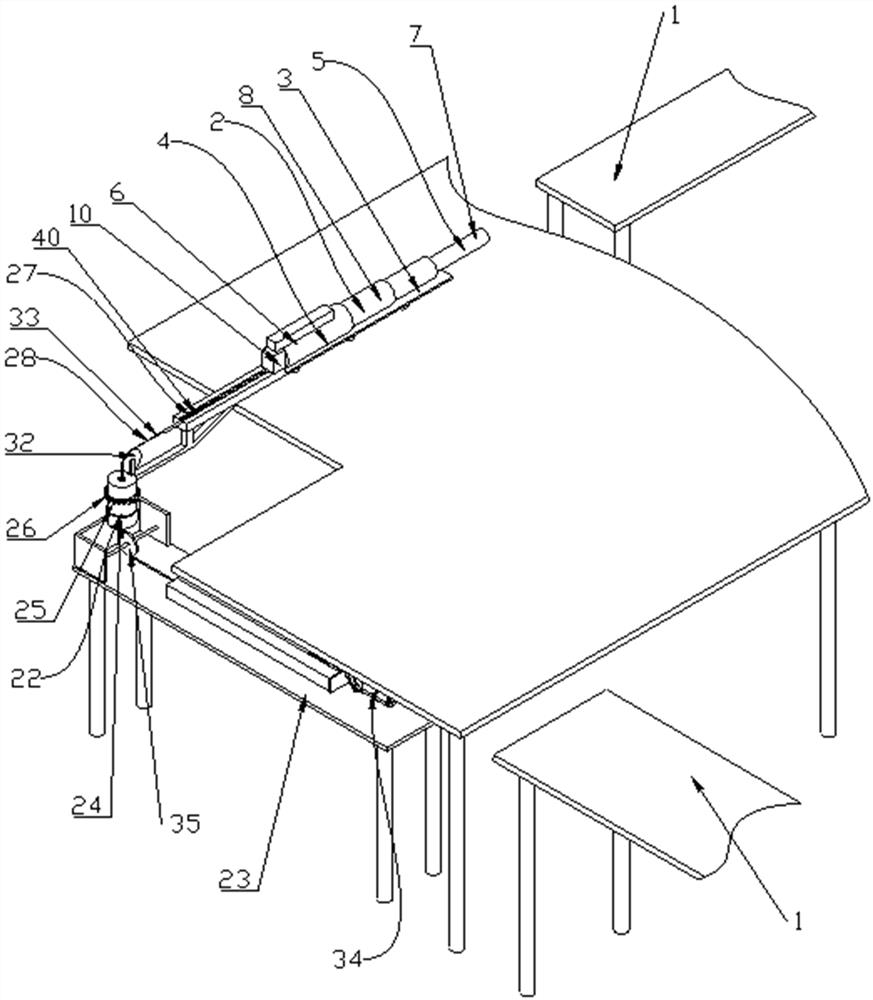

[0058] Such as Figure 1~Figure 4 As shown, this embodiment proposes a horizontal material conveying device, which can solve the problem of low material position accuracy when the material is conveyed by the conveying device in the related art. This embodiment is suitable for precisely adjusting the pushing position of the length without adjustment Situation of pushing angle.

[0059] The specific structure is as follows:

[0060] It includes a feeding platform 1 and a pushing device 2 arranged on one side of the feeding platform 1, the pushing device 2 is used to push the material on the feeding platform 1, and the support 3 of the pushing device 2 is fixed on the ground;

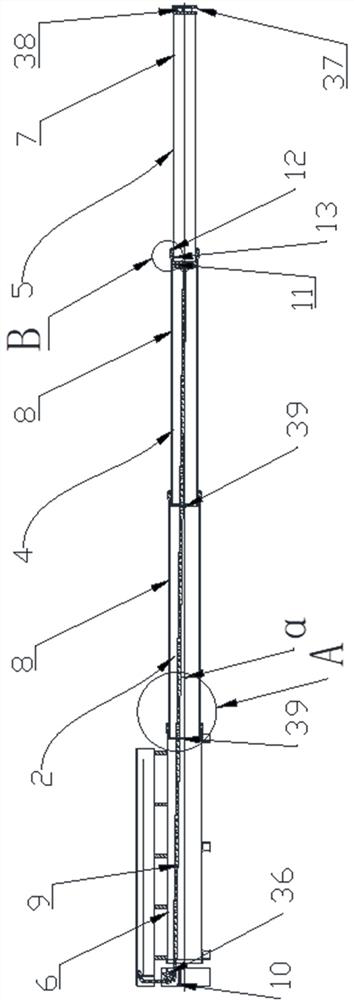

[0061] The structure of the pushing device 2 is composed of several telescopic arms 5 with different diameters. The expansion and contraction of the telescopic arms 5 is driven by the rigid chain 9, and the telescopic direction is along the horizontal direction. Other directions can also be implemented, b...

Embodiment 2

[0069] Such as Figure 1~Figure 5 As shown, this embodiment proposes a horizontal conveying device. On the basis of Embodiment 1, a mechanism capable of positioning the rigid chain 9 is added to further better solve the problem that the rigid chain 9 is heavy due to gravity during long-distance transmission. , Affected by gravity, the phenomenon of "slumping waist" appears.

[0070] Specifically, the structure adopted by the mechanism for positioning the rigid chain 9 is as follows:

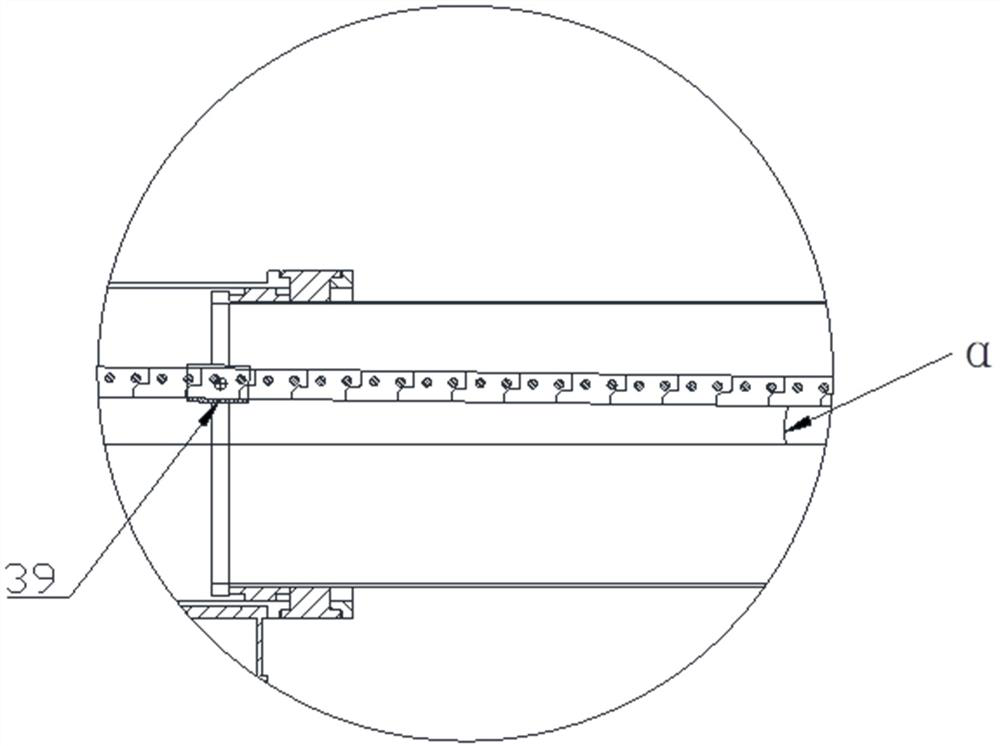

[0071] A position sensor 13 is arranged between the first protrusion 11 of one telescopic arm 5 and the second protrusion 12 of the other telescopic arm 5. When a telescopic arm 5 walks toward the direction of pushing materials, the walking telescopic arm 5 will The first protrusion 11 of the first telescopic arm 5 gradually approaches the second protrusion 12 on the rear telescopic arm 5 until the first protrusion 11 and the second protrusion 12 clamp the position sensor 13, and the first protr...

Embodiment 3

[0075] Such as Figure 1~Figure 5 As shown, this embodiment proposes a horizontal conveying device, and on the basis of Embodiment 2, a specific mechanism of the locking mechanism 14 is provided.

[0076] Specifically, the structure adopted by the locking mechanism 14 is as follows:

[0077] The clamp assembly 16 for clamping the rigid chain 9 is divided into a fixed first clamp 17 and a movable second clamp 18, the movement of the second clamp 18 is driven by the clamp drive 15, and the clamp drive 15 The opening and closing of the valve is affected by the signal of the position sensor 13.

[0078] The rigid chain 9 moves against the first clip 17, and the second clip 18 is moved and arranged in the telescopic arm 5 by means of the clamping drive device 15. The second clip 18 and the first clip 17 are respectively located on both sides of the rigid chain 9, After the second clip 18 moves, the second clip 18 and the first clip 17 clamp the rigid chain 9 in the horizontal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com