Carpet forming production line

A production line and carpet technology, applied in the field of carpet forming production line, can solve the problems of low production efficiency, complicated operation and high production cost, and achieve the effects of high production efficiency, improving processing efficiency and reducing the size of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

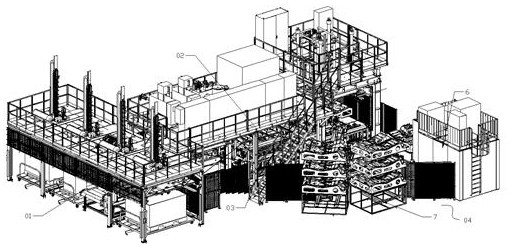

[0046]Such as figure 1 A carpet forming line shown, including

[0047] A multi-layer material automatically corrects the upper body 01, including a double-layer correction assembly and a suction cup assembly, and realizes simultaneous grab, correction and transmission of the sheets on several upper cart.

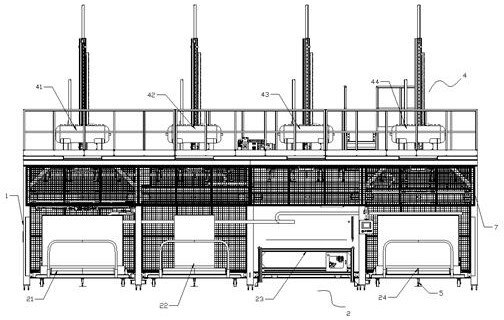

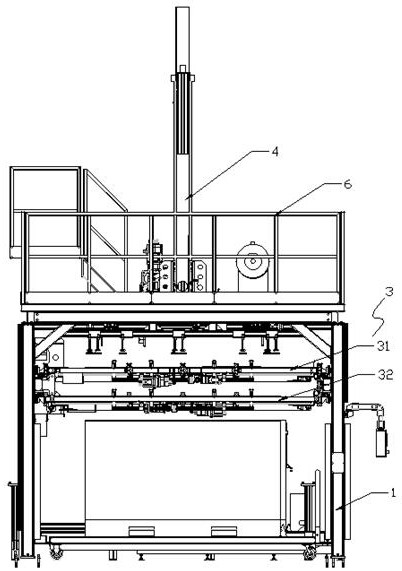

[0048] Such as Figures 2 to 4 As shown, the multilayer material automatically corrects the upper body 01, including the frame 1, the upper assembly 2, the double layer correction assembly 3, and the suction cup assembly 4.

[0049] The internal portion of the frame 1 is sequentially divided into the first upper cart region, the second upper cart region, the transfer area, and the third upper cart region along its length direction. The first charge cart 21, the second charge stroller 22, the conveyor belt 23, and the third charge trolley 24 are stored.

[0050] The upper assembly 2 includes a conveyor belt 23, a first charge cart 21, a second trolley 22, and a third trolley 24, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com