High-strength fireproof breast board

A high-strength, railing technology, applied in the direction of fire protection, railings, building components, etc., can solve the problems of property damage, deformation and separation from the aluminum alloy frame due to deformation under high temperature, deformation, loss, etc., to improve the connection strength , improve the ability to resist deformation, inhibit the spread of fire and smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

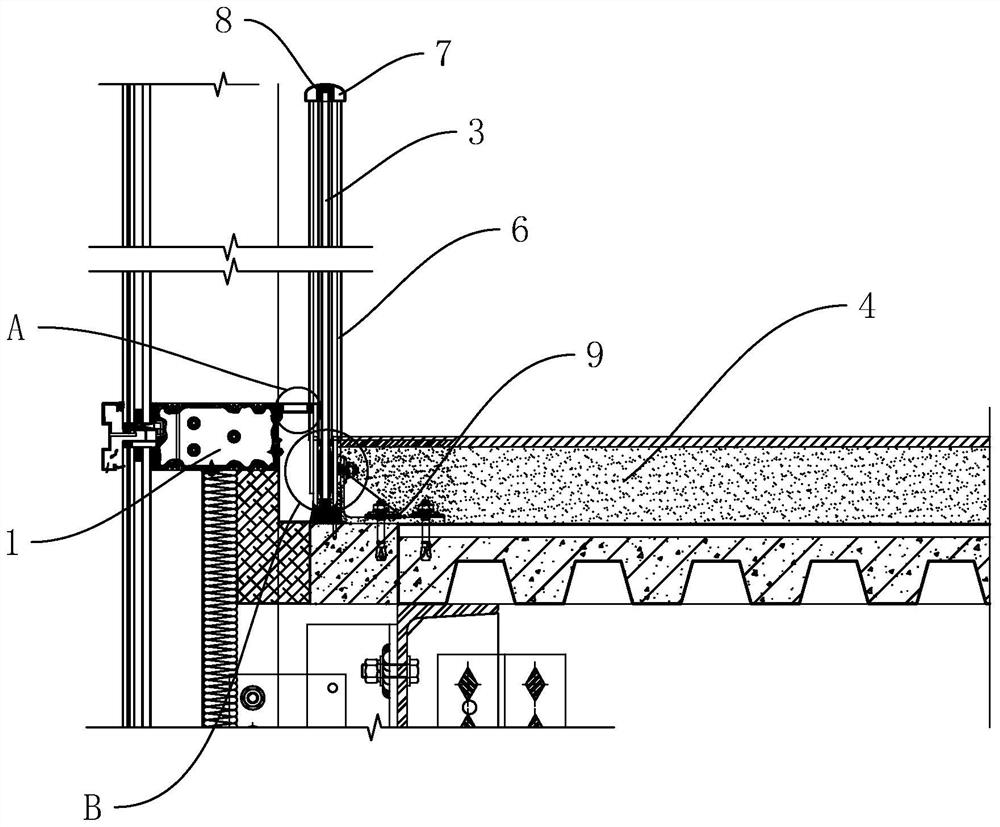

[0033] A high-strength fire barrier, such as figure 1 As shown, it includes a profile 1, an alloy frame 2 and a fireproof glass plate 3 located on the building body for connecting the glass curtain wall. The bottom end of the alloy frame 2 is fixedly connected with a pre-embedded component for connecting the building body. In order to provide a clamping force for clamping the alloy frame 2 to maintain a vertical state, the side of the fireproof glass plate 3 facing the interior is provided with a pre-embedded component and a buried layer 4 at the bottom of the alloy frame 2 .

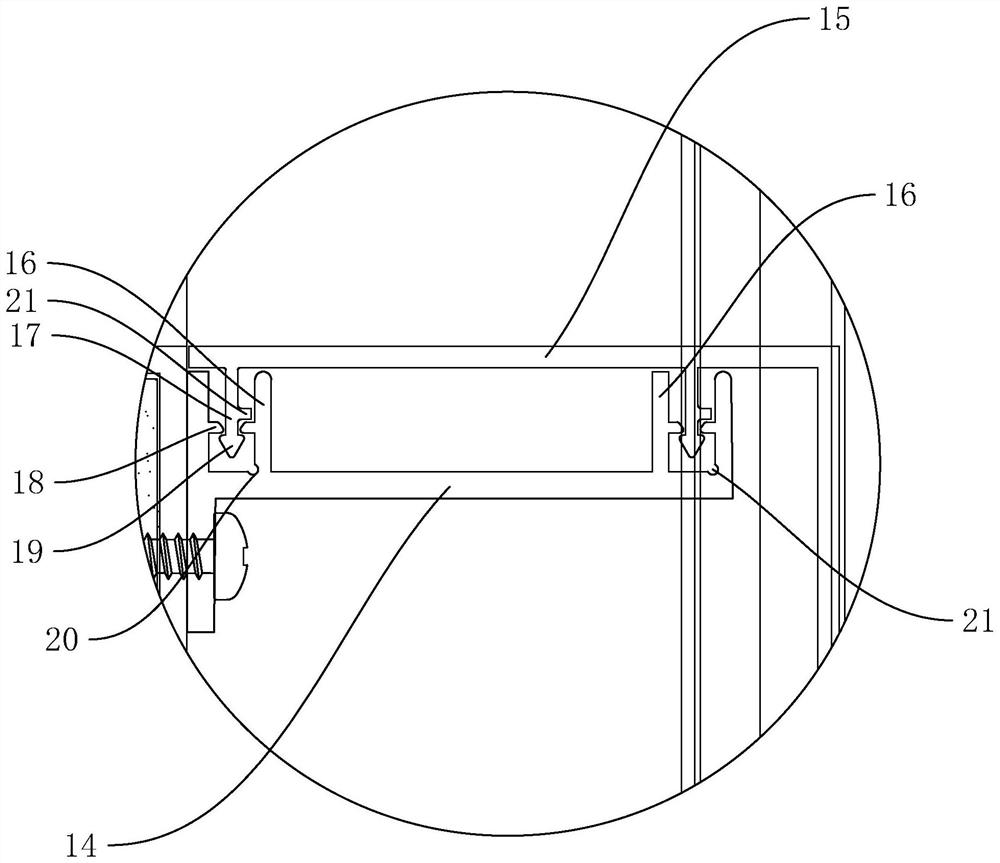

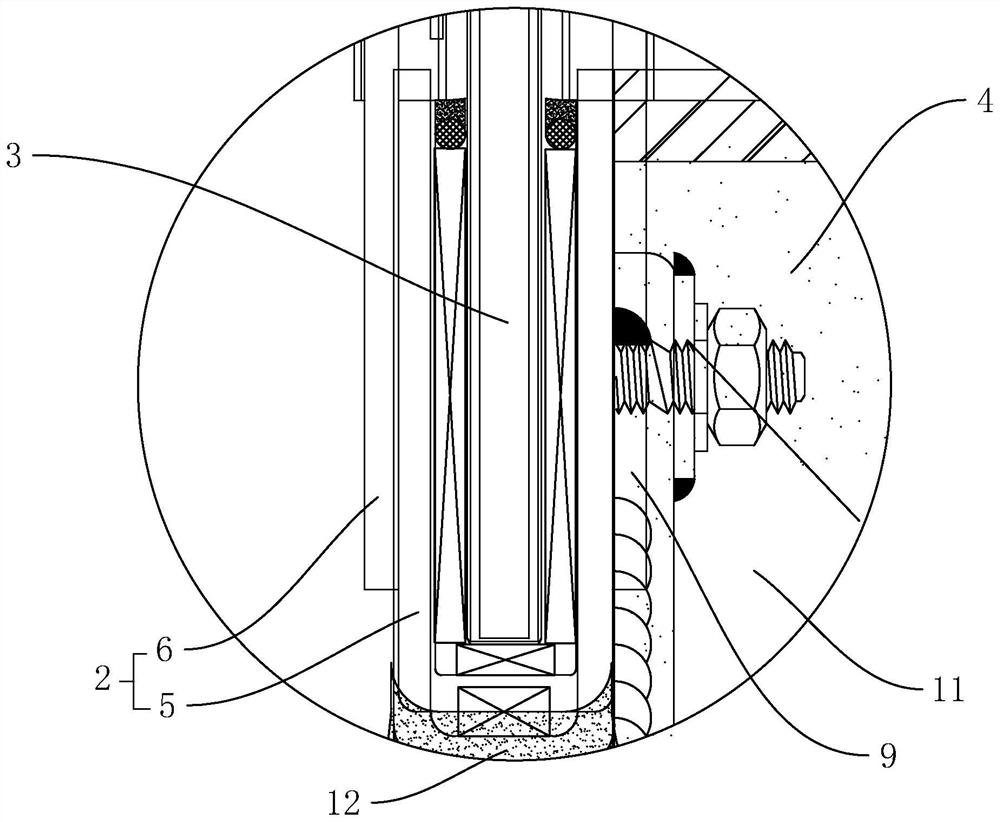

[0034] Such as figure 2 As shown, the alloy frame 2 includes a bent steel channel 5 and a column 6, the bottom end of the fireproof glass plate 3 is embedded in the bent steel channel 5, and the column 6 is located between adjacent fireproof glass panels 3 to clamp adjacent f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap