Pipe jacking method assembly type anti-floating subway station

A subway station, prefabricated technology, applied in underground chambers, shaft equipment, shaft linings, etc., can solve the problems of insignificant social and economic benefits, difficulty in anti-floating construction, and impact on residents' travel, and reduce construction safety risks. , Small footprint and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

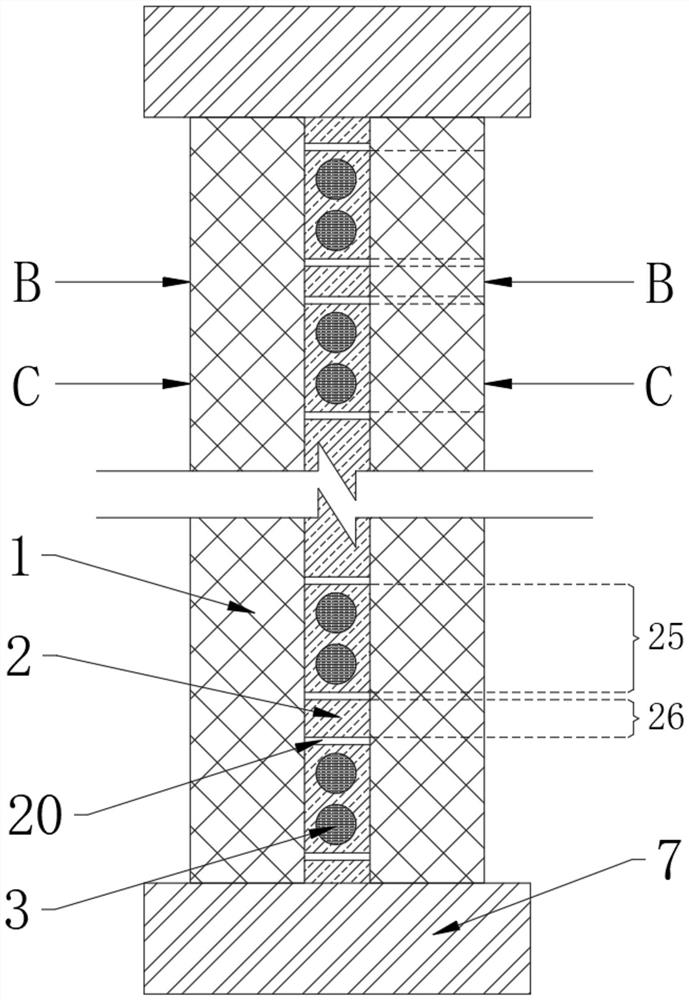

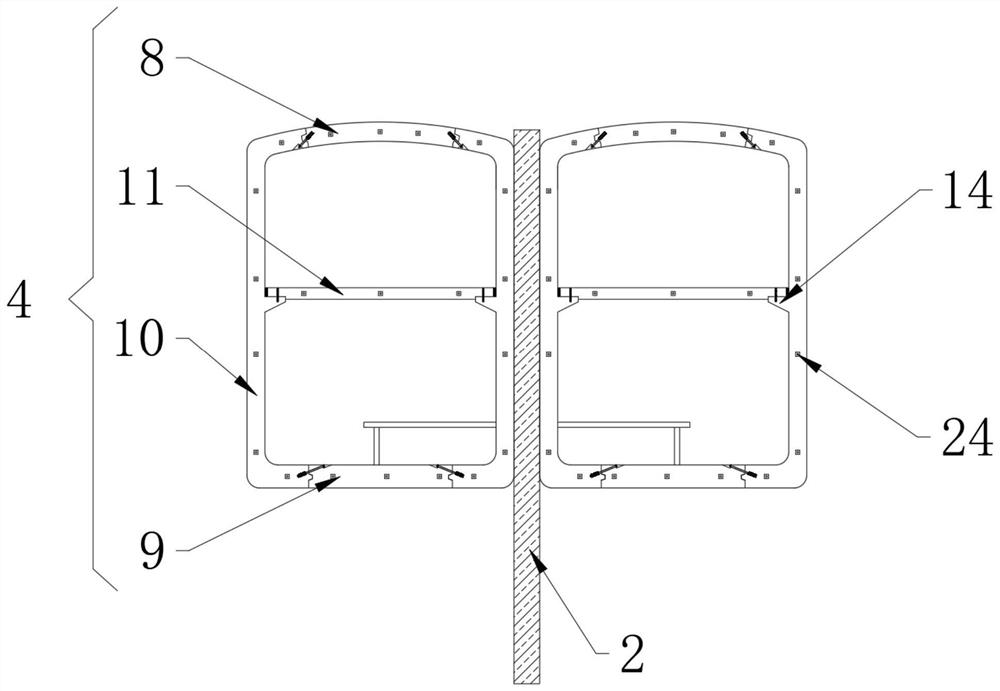

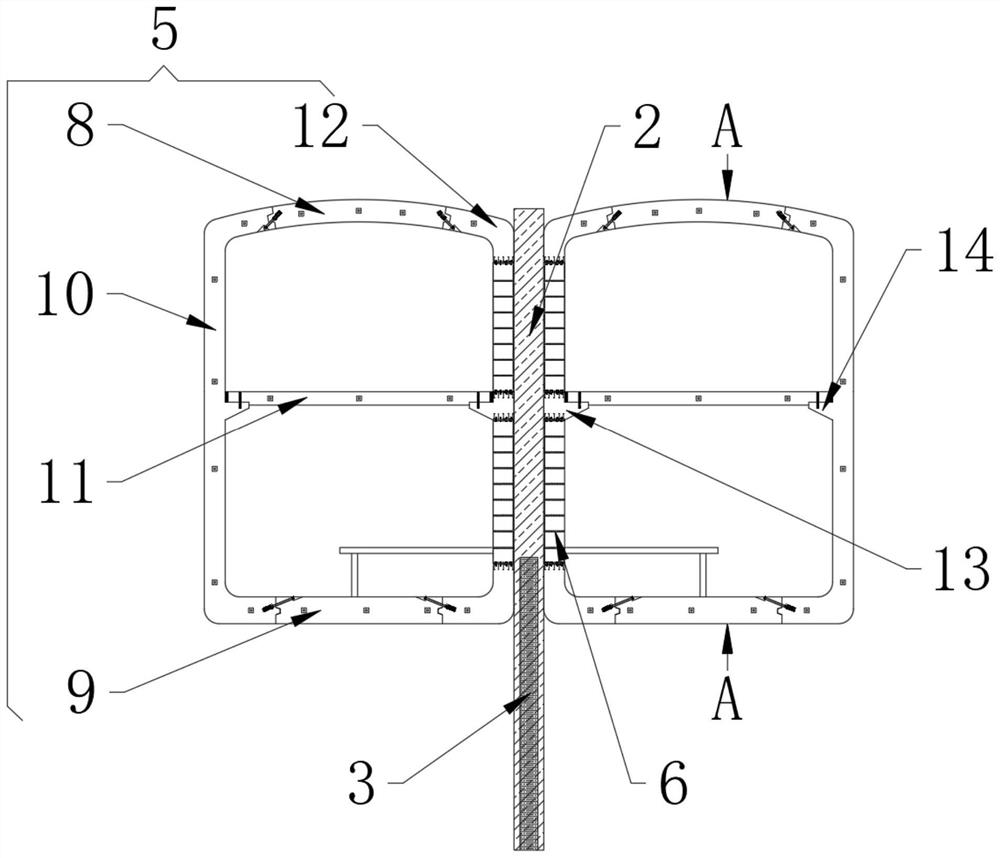

[0038] like Figure 1-Figure 8 As shown, an assembled anti-floating subway station by the pipe jacking method includes a reinforced soil body 2 and a box body 1. The box body 1 is arranged symmetrically along the reinforced soil body 2. The box body 1 is formed by alternate splicing of the first assembly and the second assembly. A connection port is provided on the second component, and a channel-reinforced steel-concrete frame is fixedly arranged along the inner periphery of the connection port. The positions of the connection ports on the boxes 1 on both sides of the reinforced soil body 2 are opposite, and between the two boxes 1 There is also a connecting channel between them, the two ends of the connecting channel are fixedly connected with the reinforced steel-concrete frame of the channel, and an uplift pile 3 is arranged in the reinforced soil 2 below the connecting channel, and the top of the uplifting pile 3 is fixedly connected with the bottom of the connecting chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com