Lifting mechanism carrying harmonic reducer and holder

A technology of harmonic reducer and lifting mechanism, applied in the field of lifting mechanism and pan/tilt, can solve the problems of large volume, heavy structure, low displacement accuracy, etc., and achieve the effect of small size, high transmission accuracy and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

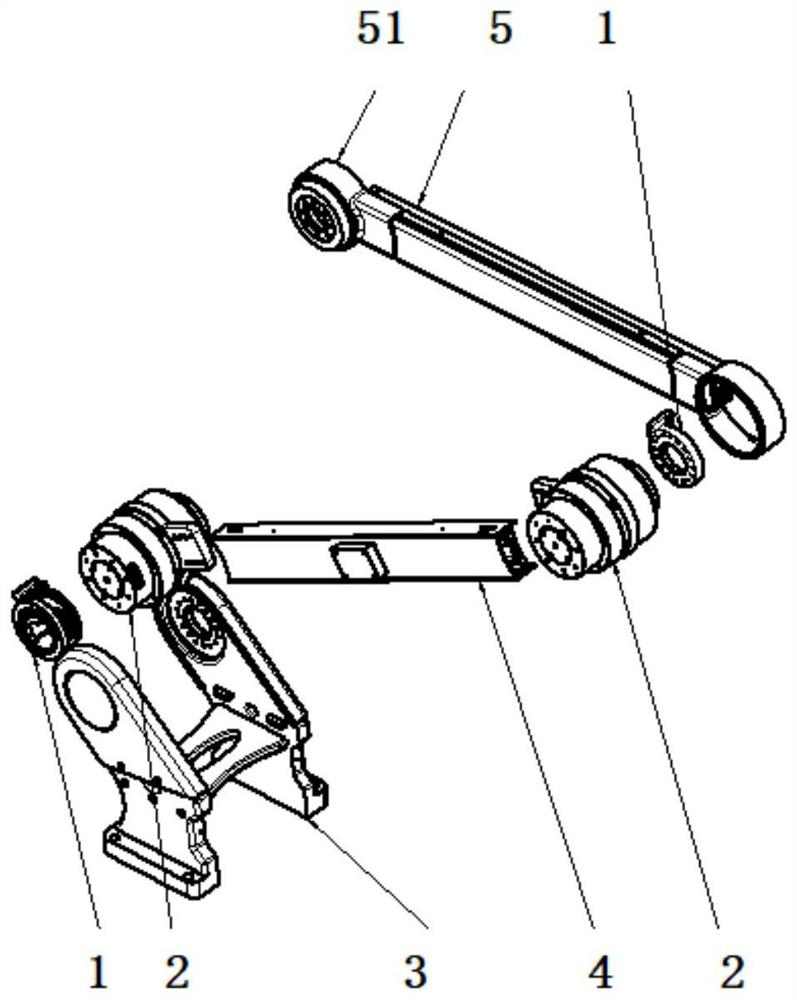

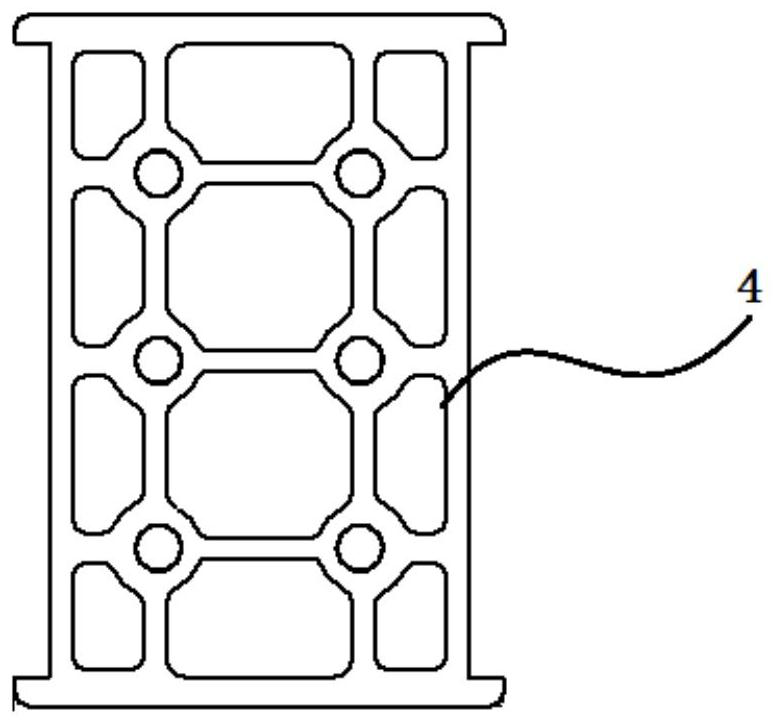

[0032] Please refer to Figure 1-5 According to the lifting mechanism of the harmonic reducer implemented in the present invention, it includes two groups of rotating parts 2, the first supporting arm 4 and the second supporting arm 5 connected by the rotating parts 2, and the first supporting arm 4 and the first supporting arm 4 A fixed base 3 connected by a rotating part 2.

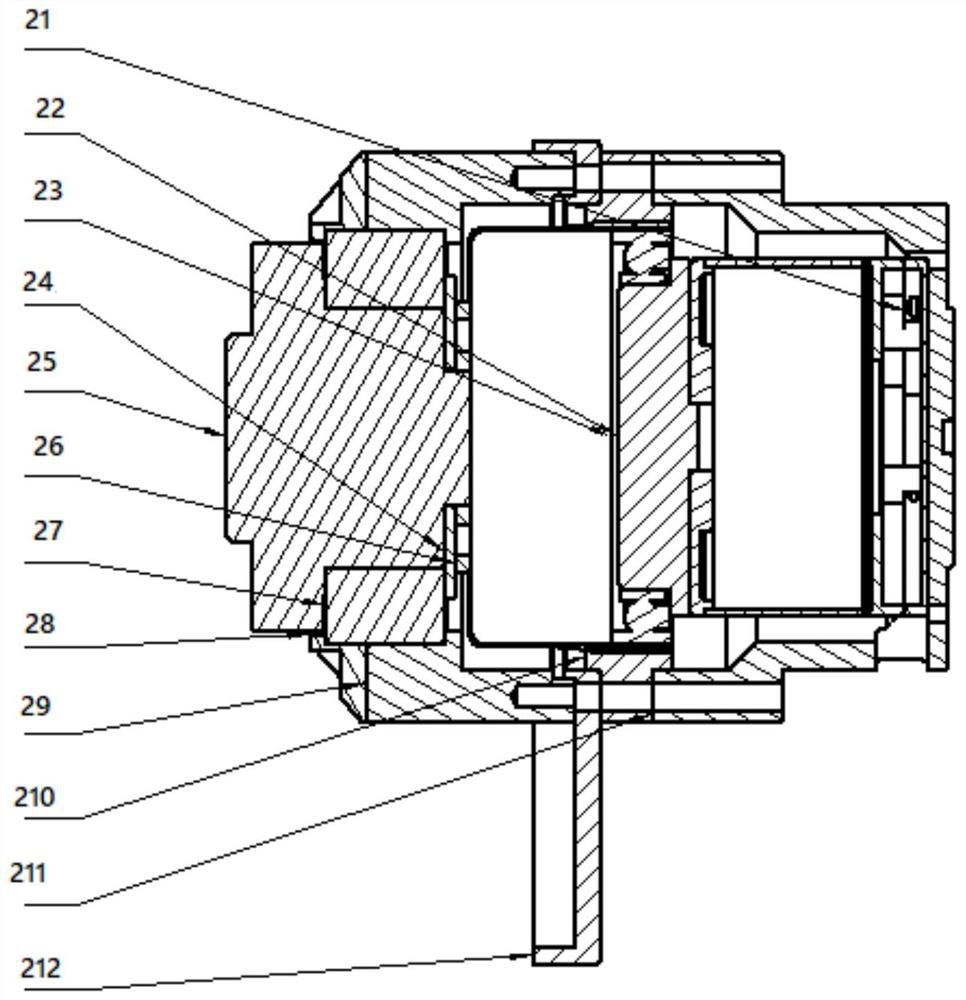

[0033] The rotating part 2 is mainly composed of a motor, a harmonic reducer, and an output flange type flexible spline fixing seat. Among them, the harmonic reducer is a reduction mechanism composed of a rigid spline, a flexible spline, a flexible bearing, and a wave generator that causes radial deformation of the flexspline. The motor directly drives the harmonic reducer, and the harmonic reducer drives the flexible spline fixed seat to rotate, and the fixed bracket is rigidly connected to the steel wheel and fixed so that it generates torque with the flexible spline fixed seat, driving the support a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap