Gas alternating generator

A generator and gas technology, applied to engine components, valve details, cocks including cut-off devices, etc., can solve problems such as noise pollution, poor control accuracy, and poor reliability, so as to avoid wear, improve air pressure control accuracy, and improve use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

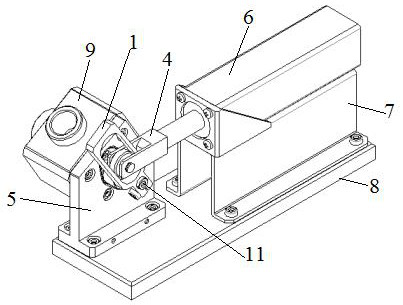

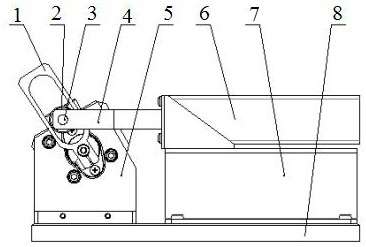

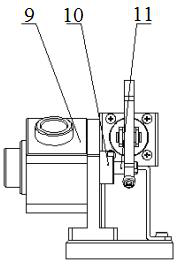

[0039] A gas alternator, such as Figure 1-Figure 5As shown, it includes a driving mechanism, a generator casing 9, and a rotating cylinder 11, the rotating cylinder 11 is installed in the generator casing 9, and one end extends out of the generator casing 9 and is connected with the connecting part. The mechanism is connected with the connecting part and drives the rotating cylinder 11 to rotate; the side wall of the rotating cylinder 11 is provided with a gray ring 14 and an O-ring 13 along the circumferential direction, and the tail end of the rotating cylinder 11 is provided with a rotating cylinder A shaft sleeve 15, and the head end is connected to the connecting part; the outer side of the generator is provided with a rotating drum fixing seat 10 that is limitedly connected with the rotating drum 11, and a stopper is arranged between the rotating drum fixing seat 10 and the rotating drum 11. Push the needle roller bearing 12, the connecting part passes through the drum ...

Embodiment 2

[0044] This embodiment is optimized on the basis of embodiment 1, such as Figure 1-Figure 4 As shown, the drive mechanism includes an electric cylinder 6, a push rod 4, a swing rod 1, and an angular contact ball bearing 2. The drive end of the electric cylinder 6 is provided with a push rod 4, and the free end of the push rod 4 is provided with a The installation groove; the swing rod 1 is connected with the installation groove through the rotating pin 3 sleeved with the angular contact ball bearing 2, the swing rod 1 is provided with a hollow cavity, and the angular contact ball bearing 2 is arranged in the hollow cavity; The bottom of the swing rod 1 is connected with the connecting part.

[0045] The free end of the push rod 4 of the electric cylinder 6 looks like a "channel steel". Put the swing rod 1 connected to the drum 11 into the groove, and connect it through the rotating pin 3 covered with the angular contact ball bearing 2. The upper part of the swing rod 1 is Ho...

Embodiment 3

[0053] This embodiment is optimized on the basis of Embodiment 1 or 2. The generator casing 9 is provided with an installation chamber inside, and the rotating drum 11 is rotatably installed in the installation chamber, and the installation chamber is correspondingly provided with an air inlet. , Exhaust port, air pressure output port.

[0054] Further, the connection part is a rod-shaped structure, preferably the connection part can be set as a slender rod structure.

[0055] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com