Air purification device for textile workshop

An air purification device and workshop technology, applied in the field of air purification, can solve the problems of low purification efficiency, downtime when replacing the filter, inconvenient installation, etc., and achieve the effects of improving air humidity, fast filtration, and convenient filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

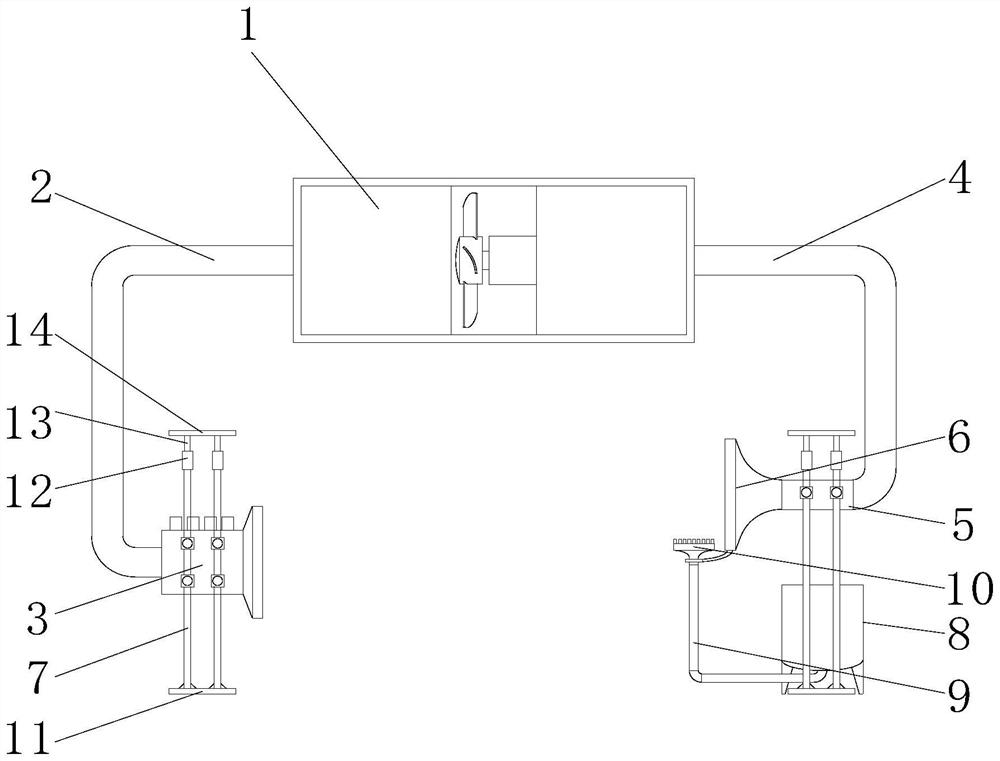

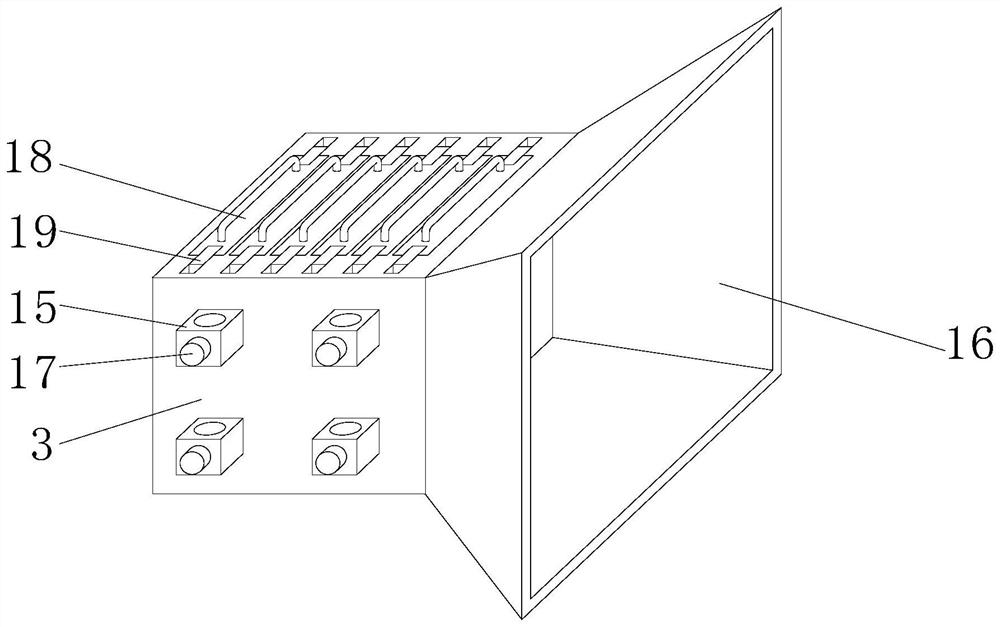

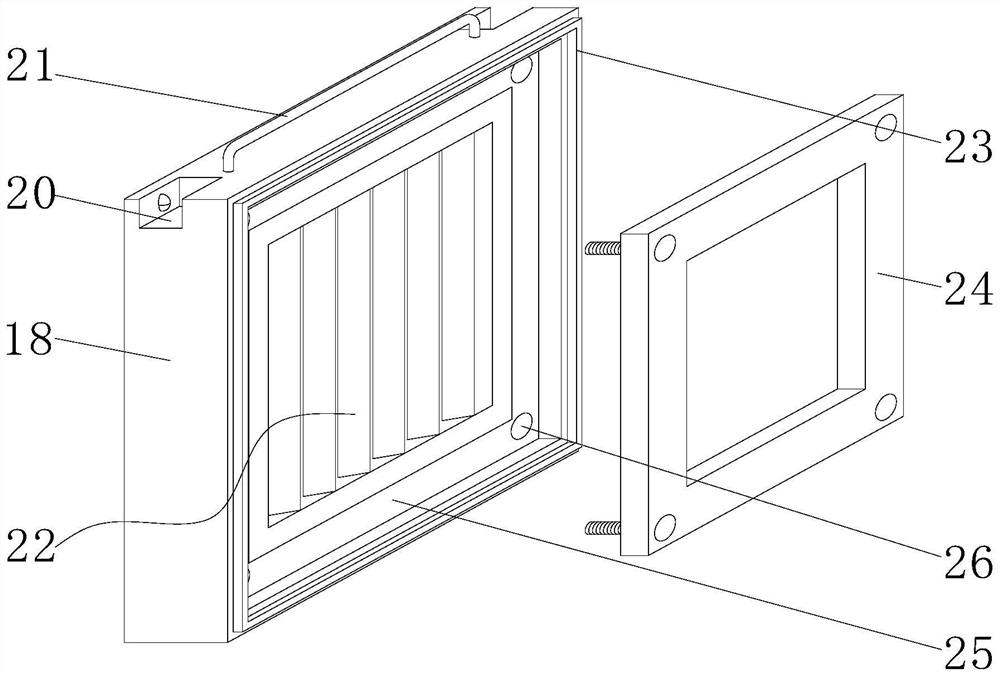

[0033] see Figure 1-6Shown: an air purification device for a textile workshop, including an air extractor 1 and a filter box 3, the input end of the air extractor 1 is equipped with an exhaust pipe 2, and the air extractor 1 passes through the air exhaust pipe 2 and one side of the filter box 3 The exhaust pipe 4 is installed on the output end of the air extractor 1, the end of the exhaust pipe 4 is installed and communicated with a receiving cylinder 5, the end of the receiving cylinder 5 is equipped with an exhaust hood 6, the filter box 3 and Exhaust hoods 6 are all installed in the textile workshop through several support columns 7. Several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com