Device and method for monitoring tower stability and filling soil hole in karst development area

A development area and monitoring rod technology, applied in the field of geotechnical engineering, can solve the problems of difficult construction, high construction cost, low monitoring accuracy, etc., to reduce construction cost and construction difficulty, facilitate monitoring and protection, and improve monitoring accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

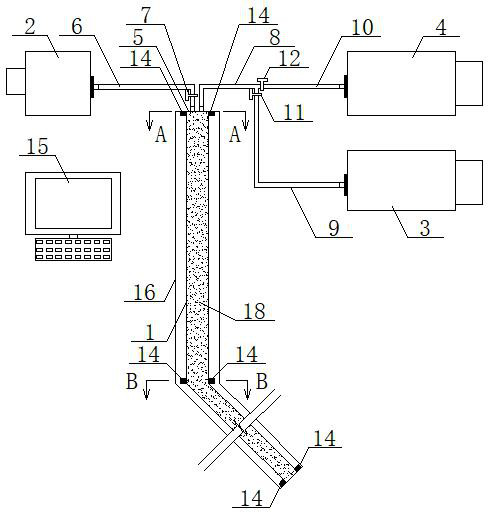

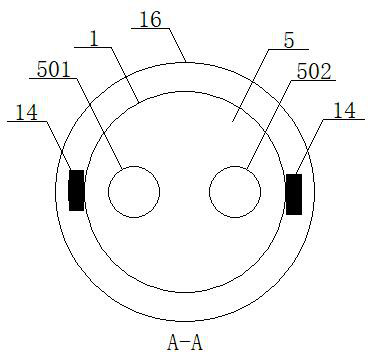

[0049] see Figure 1 to Figure 5 , a device for monitoring tower stability and filling soil holes in a karst development area, including a material pipe 1, an air supply device 2, a sand supply device 3 and a slurry supply device 4, one end of the material pipe 1 is located on the ground, and the end An end cover 5 is provided, and an air inlet 501 and a feeding hole 502 communicating with the material pipe 1 are opened on the end cover 5, and the air inlet 501 is communicated with one end of the air delivery pipe 6, and the other end of the air delivery pipe 6 is connected with the air supply pipe 6. The gas equipment 2 is connected, and the gas delivery pipe 6 is provided with a first valve 7, and the feed hole 502 is connected with one end of the feeding pipe 8, and the other end of the feeding pipe 8 is respectively connected with the sand delivery pipe 9 and the delivery pipe 9 through a three-way joint. One end of the slurry pipe 10 is connected, and the other ends of th...

Embodiment 2

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] Described device also comprises controller 15, and the signal input end of described controller 15 is connected with the signal output end of monitoring equipment 14, and the signal output end of controller 15 is connected with gas supply equipment 2, sand supply equipment 3, slurry supply equipment respectively. 4. The first valve 7, the second valve 11, and the third valve 12 are connected.

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

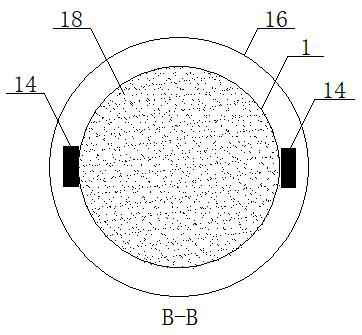

[0060]The device also includes a borehole protection tube 16, which is sleeved outside the material pipe 1, one end of the borehole protection tube 16 is located on the ground, and the other end of the borehole protection tube 16 extends to be close to the soil hole 13 The borehole protection pipe 16 is connected with the pressure tower 17, the pressure tower 17 includes a main rod 171 and a base 172, the main rod 171 is a cylindrical structure, and the base 172 is a conical structure, The base 172 is located underground, the top of the base 172 is connected to one end of the main rod 171, and the other end of the main rod 171 extends to the ground. The borehole protection pipe 16 includes a vertical cylinder 161 and an inclined cylinder 162. One end of the straight cylinder 161 is located on the ground, and the other end of the vertical cylinder 161 communicates with an end of the inclined cylinder 162 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com