Packaging colloid, high-brightness mini-LED structure and manufacturing process of mini-LED structure

A mini-led, encapsulating colloid technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of light energy loss, brightness decline, etc., to achieve the effect of high brightness, not easy to damage, and convenient manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

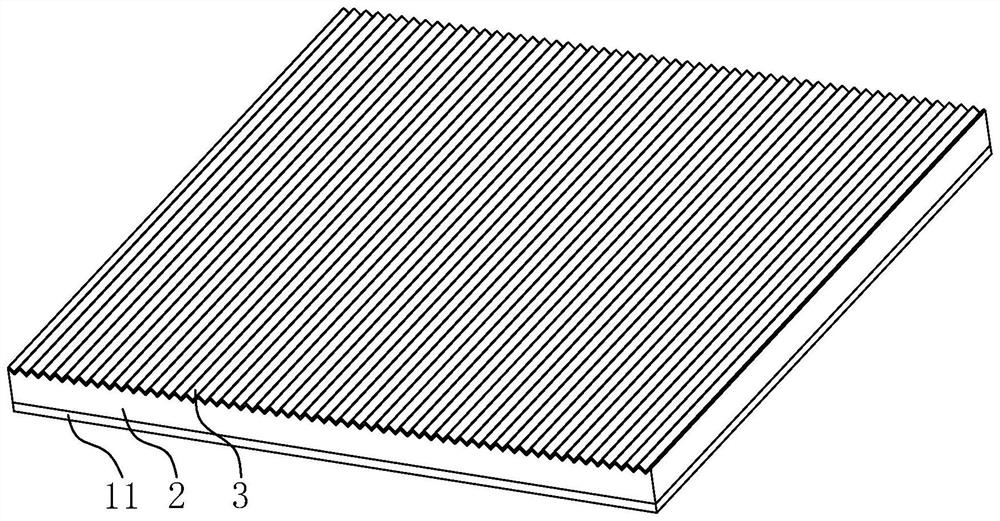

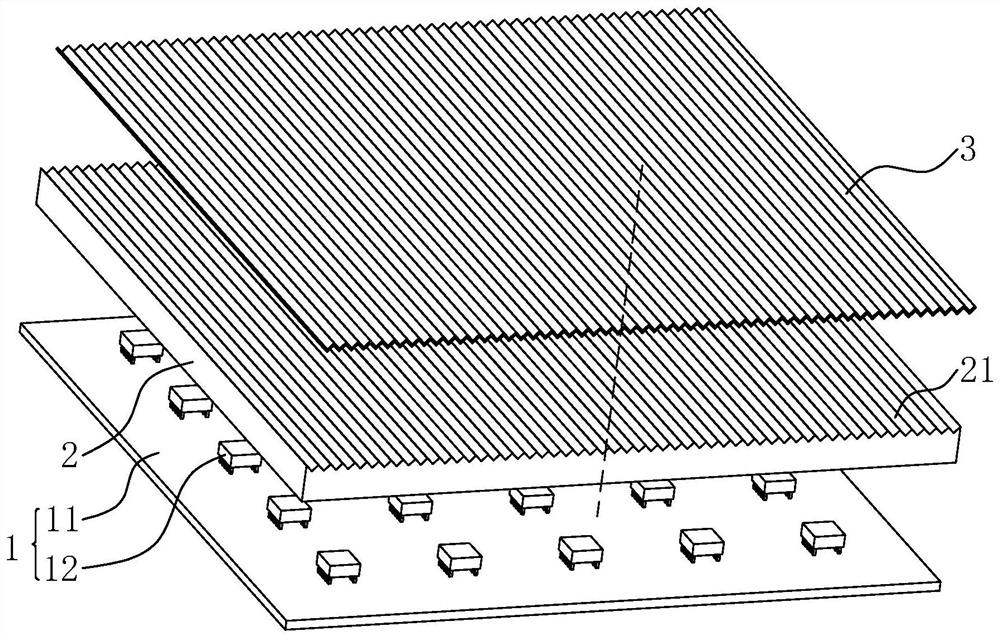

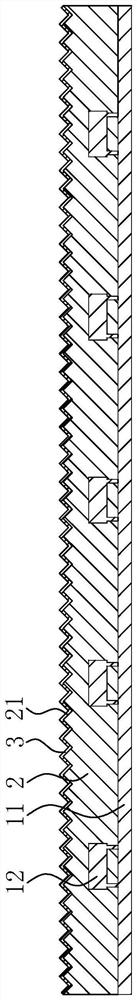

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of the present application discloses an encapsulation colloid.

[0037] refer to figure 1 and figure 2 , an encapsulant for encapsulating light-emitting chips on a substrate 11, including an encapsulant 2 made of UV glue, one side of the encapsulant 2 is provided with several V-shaped grooves 21, and two adjacent V-shaped grooves The groove walls of 21 are in contact, the notch opening angle of V-shaped groove 21 is 20-105°, the groove bottom distance between two adjacent V-shaped grooves 21 is 0.05-0.2mm, and the depth of V-shaped groove 21 is 0.05-0.2mm. mm.

[0038] When in use, the V-shaped groove 21 on the encapsulant 2 refracts and diverges the light of the mini-LED, so that the point light source of the mini-LED tends to be a planar light source, so that the point light source of the light-emitting chip does not need to diffuse through multiple layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com