Nanometer zero-valent iron-loaded ceramsite and preparation method thereof

A technology of nano-zero-valent iron and ceramsite, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of high production cost, complicated preparation process and harsh technical parameters of nano-zero-valent iron , to achieve the effects of short reaction cycle, simple raw material composition and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

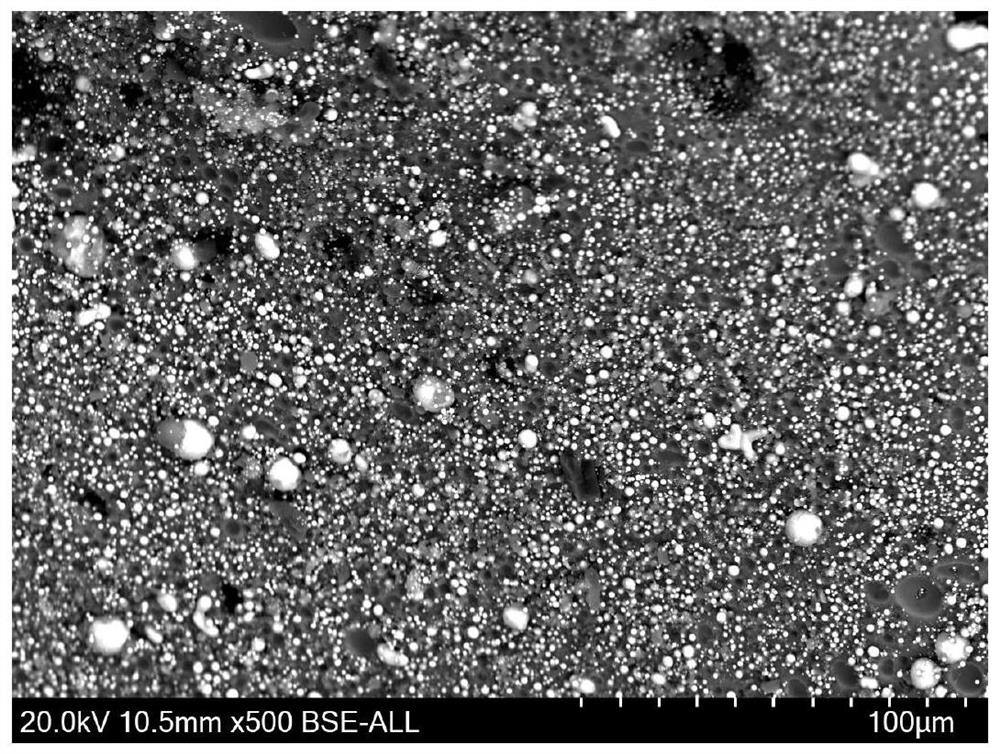

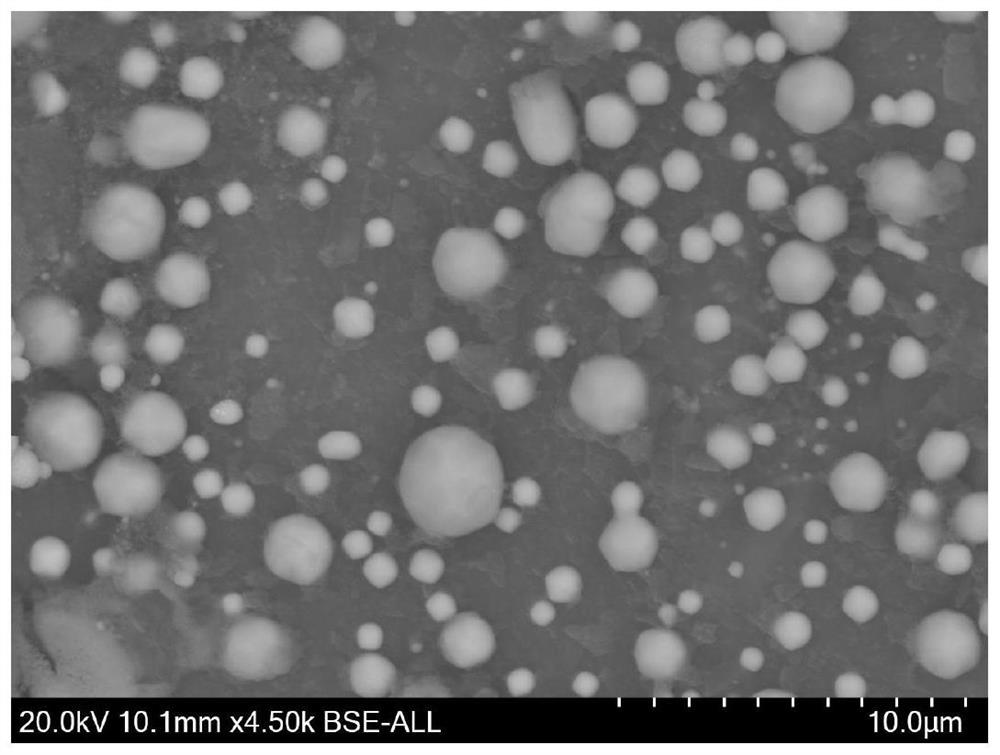

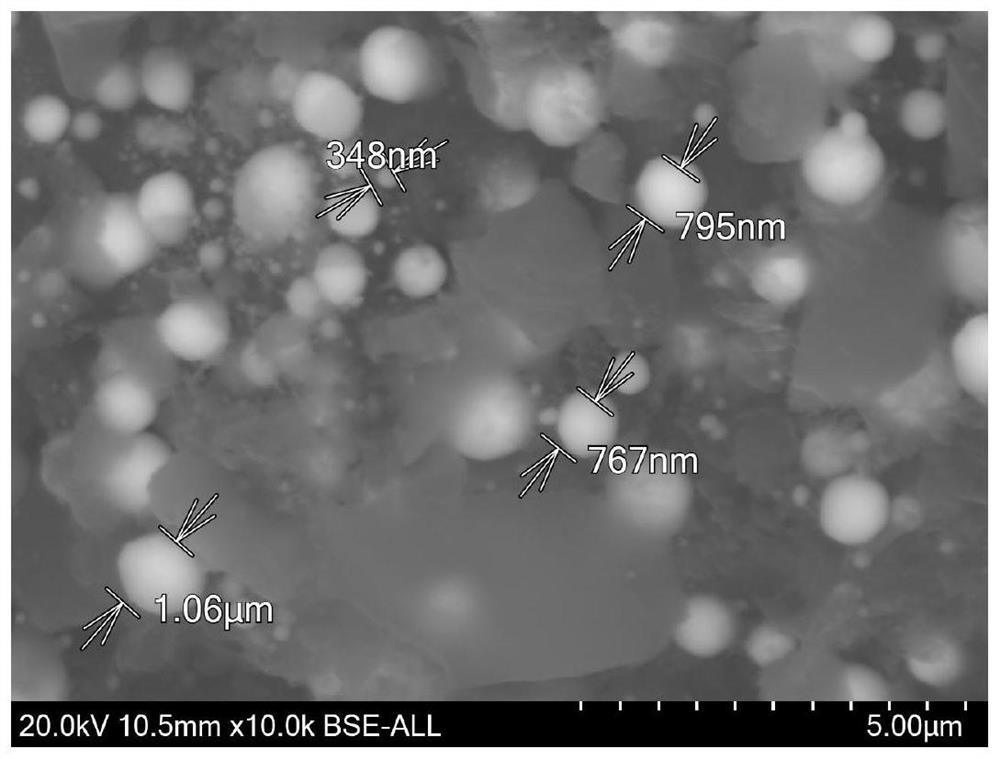

Image

Examples

Example Embodiment

[0036] Example 1

[0037] A kind of loaded nanometer zero-valent iron ceramsite and preparation method thereof, comprising the following steps:

[0038] (1) Dry and screen 45 parts by mass of fluorite tailings, 45 parts by mass of waste glass, 10 parts by mass of kaolin, and 20 parts by mass of blast furnace dust;

[0039] (2) weighing the raw materials after sieving, and mixing in proportion to obtain a mixture;

[0040] (3) Grinding the mixture in a ball mill to obtain a mixed concentrate with a particle size lower than 200 mesh;

[0041] (4) Molding and pressurizing the mixed concentrate;

[0042] (5) Carry out drying treatment to the mold with the charge, the drying temperature is 85°C, and the drying time is 2h;

[0043] (6) The dried green balls are sent to a heating furnace for roasting, and in an inert atmosphere, the temperature is raised to 1100°C at a heating rate of 10°C / min, and heat treatment is carried out for 30 minutes;

[0044] (7) After constant temperat...

Example Embodiment

[0045] Example 2

[0046] A ceramsite loaded with nanometer zero-valent iron and a preparation method thereof, comprising the following steps:

[0047] (1) 40 parts by mass of fluorite tailings, 45 parts by mass of waste glass, 15 parts by mass of kaolin, and 10 parts by mass of blast furnace dust are separately dried and sieved;

[0048] (2) weighing the raw materials after sieving, and mixing in proportion to obtain a mixture;

[0049] (3) Grinding the mixture in a ball mill to obtain a mixed concentrate with a particle size lower than 200 mesh;

[0050] (4) Molding and pressurizing the mixed concentrate;

[0051] (5) Carry out drying treatment to the mold of charging, drying temperature is 80 ℃, drying time is 4h;

[0052] (6) The dried green balls are sent to a heating furnace for roasting, and in an inert atmosphere, the temperature is raised to 1000°C at a heating rate of 10°C / min, and heat treatment is carried out for 40 minutes;

[0053] (7) After constant temperatur...

Example Embodiment

[0054] Example 3

[0055] A kind of loaded nanometer zero-valent iron ceramsite and preparation method thereof, comprising the following steps:

[0056] (1) Dry and screen 50 parts by mass of fluorite tailings, 45 parts by mass of waste glass, 5 parts by mass of kaolin, and 30 parts by mass of blast furnace dust;

[0057] (2) weighing the raw materials after sieving, and mixing in proportion to obtain a mixture;

[0058] (3) Grinding the mixture in a ball mill to obtain a mixed concentrate with a particle size lower than 200 mesh;

[0059] (4) Molding and pressurizing the mixed concentrate;

[0060] (5) Carry out drying treatment to the mold loaded with material, the drying temperature is 100° C., and the drying time is 3 hours;

[0061] (6) The dried green balls are sent to a heating furnace for roasting, and in an inert atmosphere, the temperature is raised to 1200°C at a heating rate of 10°C / min, and heat treatment is carried out for 20 minutes;

[0062] (7) After const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Biggest size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com