Low-permanent-deformation reel cable sheath material

A technology of cable sheathing and permanent deformation, which is applied to circuits, electrical components, plastic/resin/wax insulators, etc. It can solve problems such as low production efficiency, inability to easily extrude cables, and expensive neoprene rubber, so as to improve smoothness. Effects of slipperiness, improvement of material extrusion process, and reduction of material cost and price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

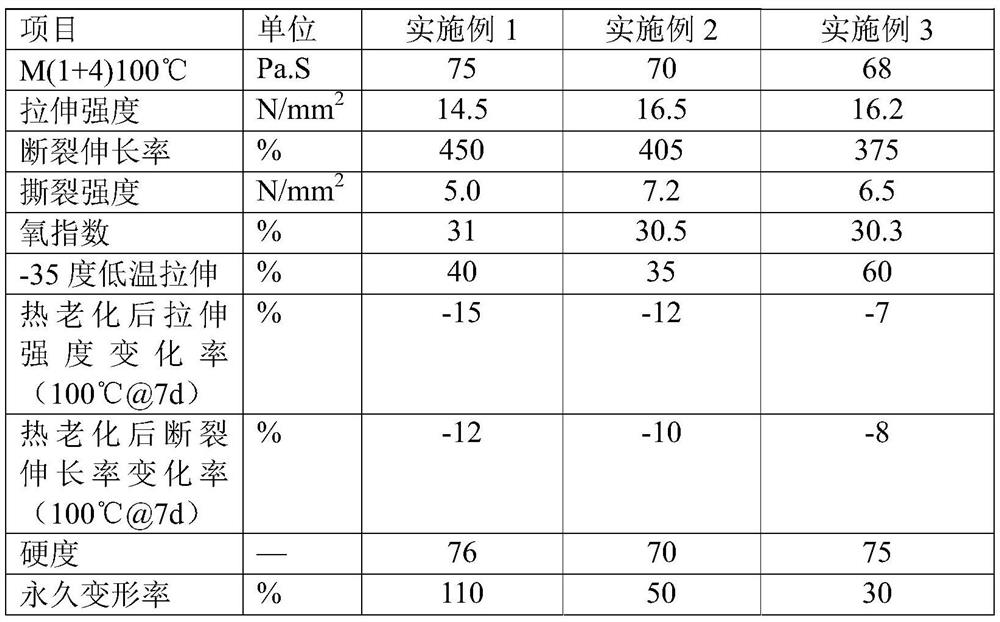

Embodiment 1

[0032] A low permanent deformation reel cable sheath material, made from the following raw materials in parts by weight:

[0033] 100 parts of CPE, 0 parts of CR, 0 parts of EVA, 10 parts of carbon black, 70 parts of talcum powder, 0 parts of calcium carbonate, 10 parts of silicon dioxide, 3 parts of antimony trioxide, 5 parts of magnesium oxide, 15 parts of DOA, anti-aging Agent RD 1 part, TAIC 1.5 parts and DCP 3 parts.

Embodiment 2

[0035] A low permanent deformation reel cable sheath material, made from the following raw materials in parts by weight:

[0036] 70 parts of CPE, 30 parts of CR, 0 parts of EVA, 10 parts of carbon black, 60 parts of talcum powder, 10 parts of calcium carbonate, 10 parts of silicon dioxide, 3 parts of antimony trioxide, 5 parts of magnesium oxide, 15 parts of DOA, anti-aging Agent RD 1 part, TAIC 1.5 parts and DCP 3 parts.

Embodiment 3

[0038] A low permanent deformation reel cable sheath material, made from the following raw materials in parts by weight:

[0039] 60 parts of CPE, 30 parts of CR, 10 parts of EVA, 10 parts of carbon black, 40 parts of talcum powder, 30 parts of calcium carbonate, 10 parts of silicon dioxide, 3 parts of antimony trioxide, 5 parts of magnesium oxide, 15 parts of DOA, anti-aging Agent RD 1 part, TAIC 1.5 parts and DCP 3 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com