Oil seed frying machine

A seed frying machine and oil material technology, which is applied in the field of seed frying machines, can solve the problems of high feeding port, inconvenient feeding, heat loss, etc., and achieve the effects of firm support, convenient stir frying, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

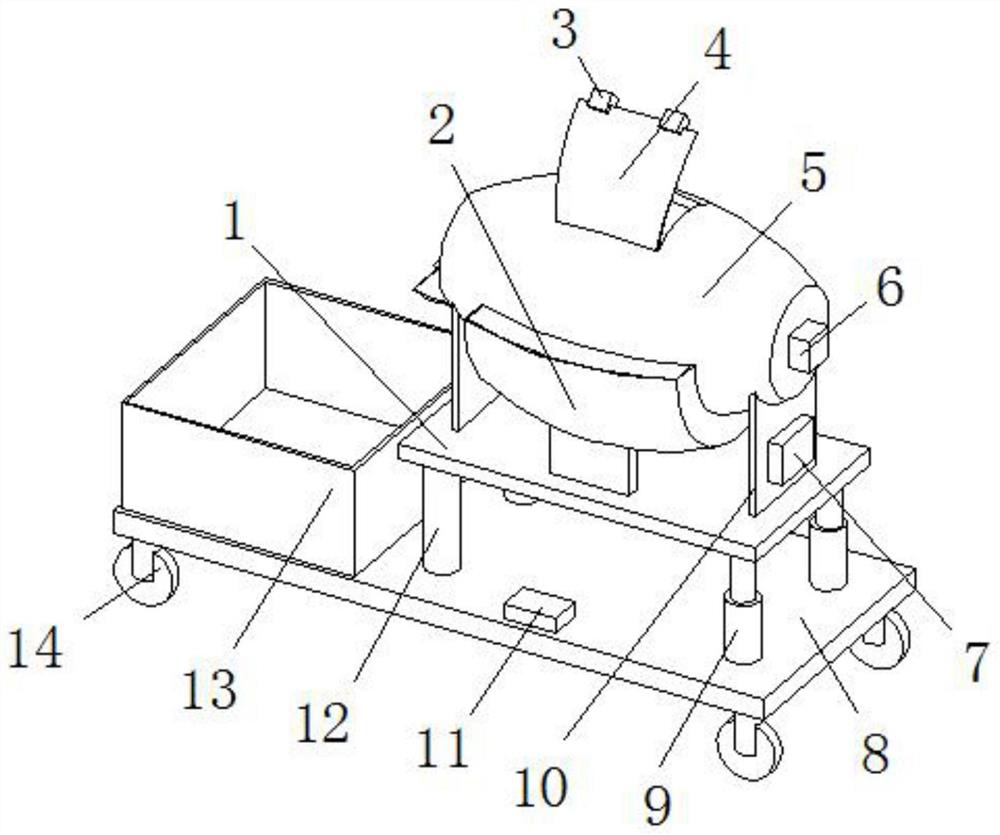

Embodiment 1

[0037] Beneficially, wherein, the frying seed device includes a lower side housing 62, a sliding cavity 63 is provided in the lower side housing 62, a top side housing 61 is provided for sliding in the sliding cavity 63, and one side of the top side housing 61 A protruding plate 71 is provided, and a latch 69 is provided in the lower housing 62, and the convex plate 71 and the latch 69 are engaged and arranged, and an inner cavity 66 is provided in the lower housing 62 and the top housing 61, and the top housing One side of the body 61 is provided with a clamping track 39, one side of the clamping track 39 is provided with several connecting blocks 31, and one side of the sliding cavity 63 is provided with an annular loading cavity 78 located in the lower housing 62, and the annular loading cavity 78 A number of loading blocks 64 are set up against each other. The connecting block 31 and the loading block 64 are provided with heating components that are matched and connected wi...

Embodiment 2

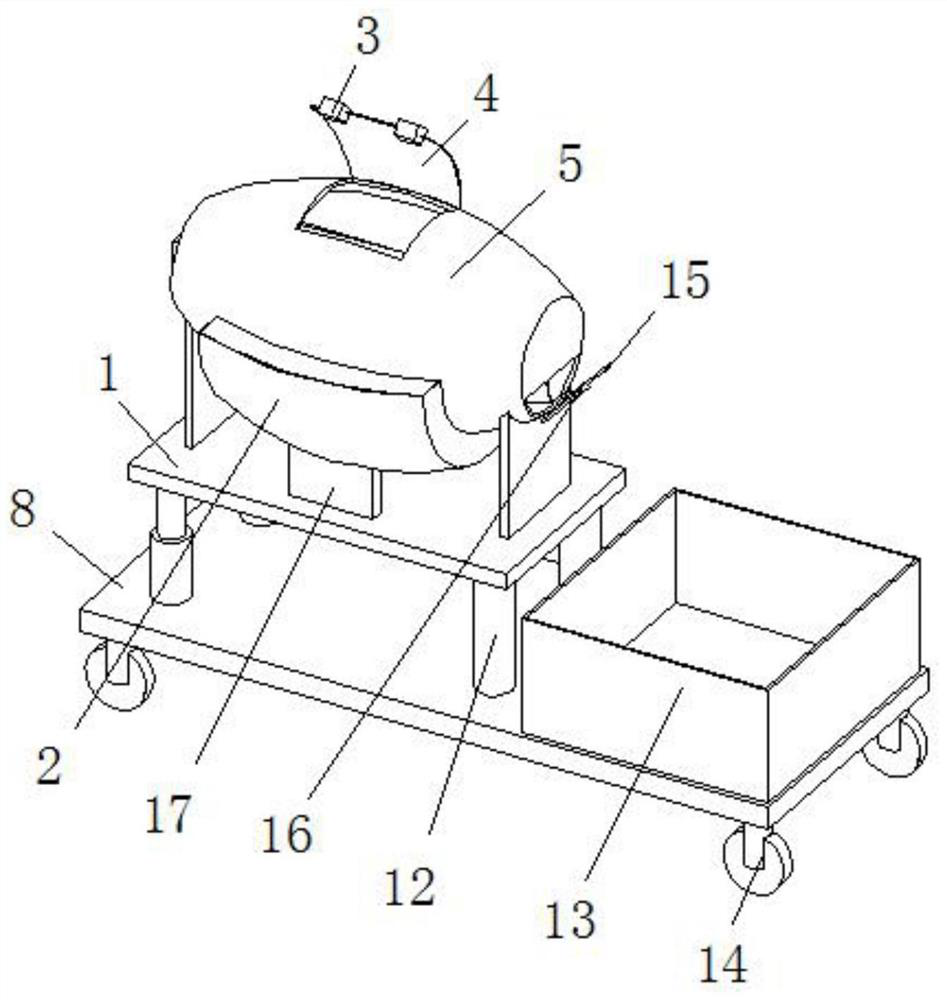

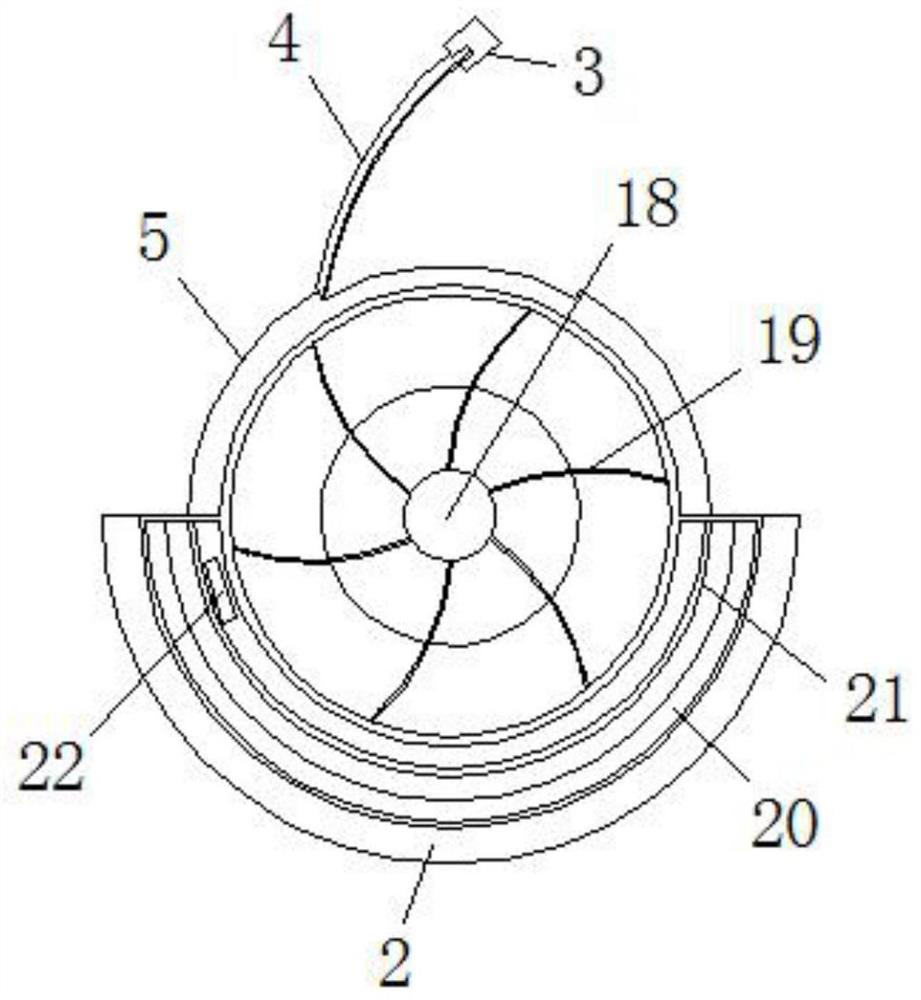

[0042] Beneficially, wherein, the stir-fried seed device includes a fried seed shell 5 connected by welding between the interior of the upper end groove of the first support plate 10, the fried seed shell 5 is an ellipsoidal structure, and the inner two ends of the fried seed shell 5 pass through The bearing is connected with a stir-fry rotating shaft 18, and the outer side of the stir-fry rotating shaft 18 is provided with a stir-frying scraper 19, which is connected with the stir-fry rotating shaft 18 by welding, and the distance between the stir-fry scraper 19 and the turning One side of the stir-fry rotating shaft 18 is connected to the inner side of the stir-fry seed shell 5, and one end of the stir-fry seed shell 5 is connected with a stir-fry motor 6 by bolts, and the output shaft of the stir-fry motor 6 runs through one side of the stir-fry seed shell 5, And the output shaft of the stir-frying motor 6 is connected with one end of the stir-frying rotating shaft 18, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com