Method for purifying plasmids

A plasmid, calcium chloride solution technology, applied in DNA preparation, recombinant DNA technology and other directions, can solve the problems of ineffective removal of pollutants, increase removal costs, etc., and achieve the effects of removing RNA pollution, simple operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1. Purify plasmid with the method of the present invention

[0018] 1. Alkaline lysis of E. coli culture: resuspend the E. coli culture containing the plasmid to be purified evenly with resuspension buffer (TE buffer, pH8.0), and then add an equal proportion of lysate (0.2M NaOH+2 % SDS solution), after 5 minutes, add an equal proportion of 3M potassium acetate buffer to neutralize to obtain 3L lysate;

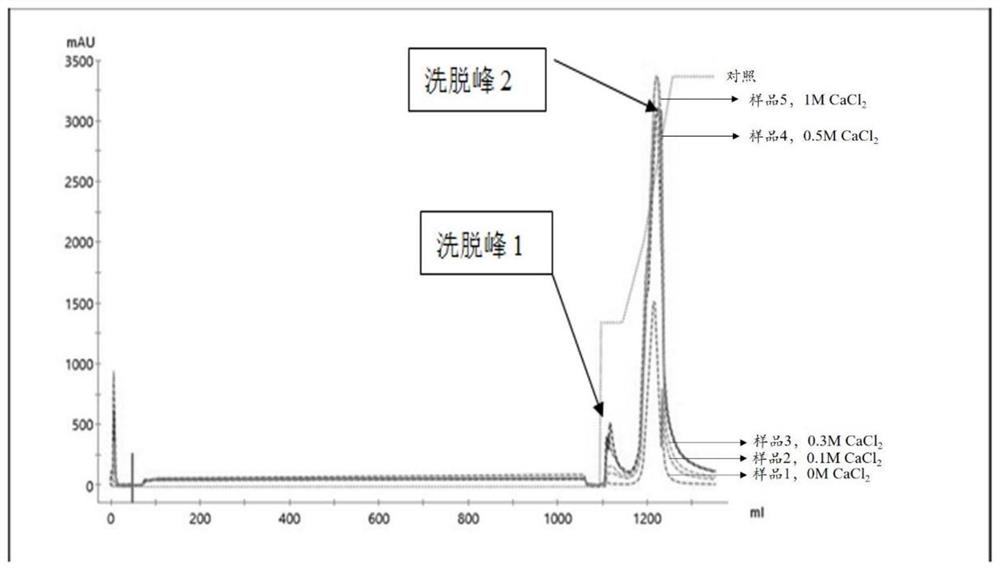

[0019] 2. Divide the lysate into 5 parts, 600ml each, add 125ml of ultrapure water to one of them (that is, the concentration of calcium chloride is 0, sample 1), and add 125ml of various concentrations of CaCl 2 Solution (pH5.0-7.0), so that the final calcium chloride concentration in the system is 0.1M (sample 2), 0.3M (sample 3), 0.5M (sample 4), 1M (sample 5).

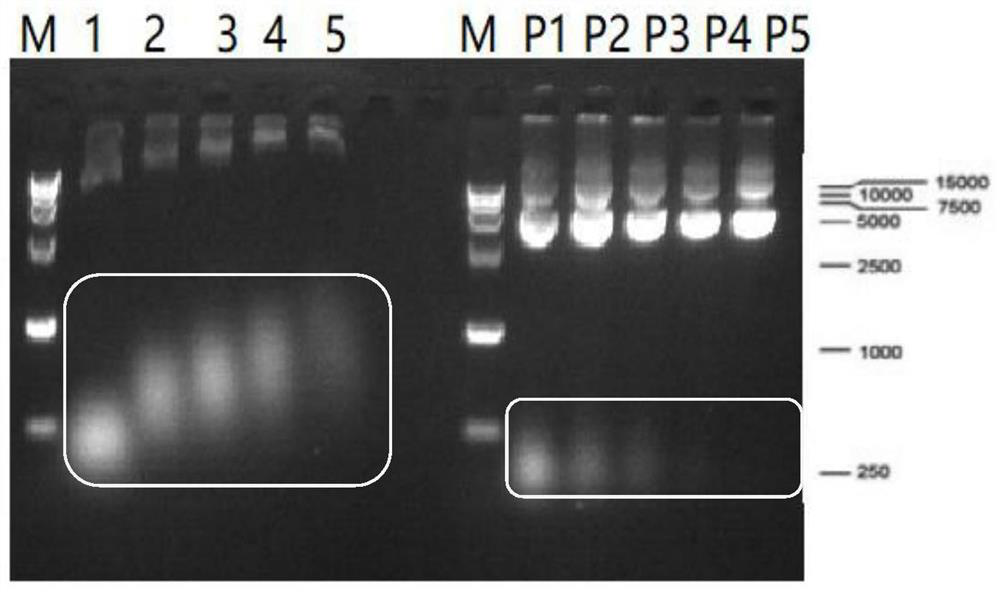

[0020] 3. After standing at room temperature for 30 minutes, take 10 μl of the supernatant for electrophoresis (for electrophoresis results, see figure 1 1-5 in ), and take 400ml supernatant, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com