Pickling equipment for surface rust-proof treatment of copper alloy parts

A technology of anti-rust treatment and pickling equipment, applied in the field of pickling equipment, can solve the problems of accelerating the acidification speed of rust, reducing the labor intensity of workers, increasing the labor intensity of workers, etc., and achieving the effect of accelerating the acidizing speed and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

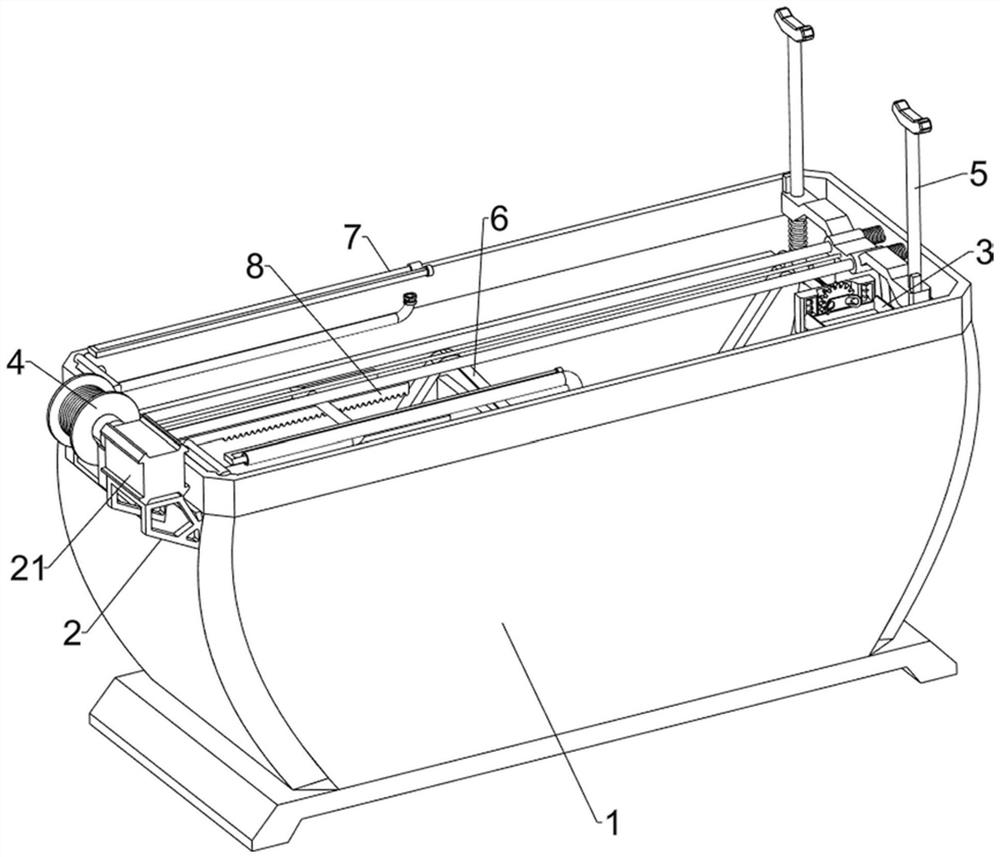

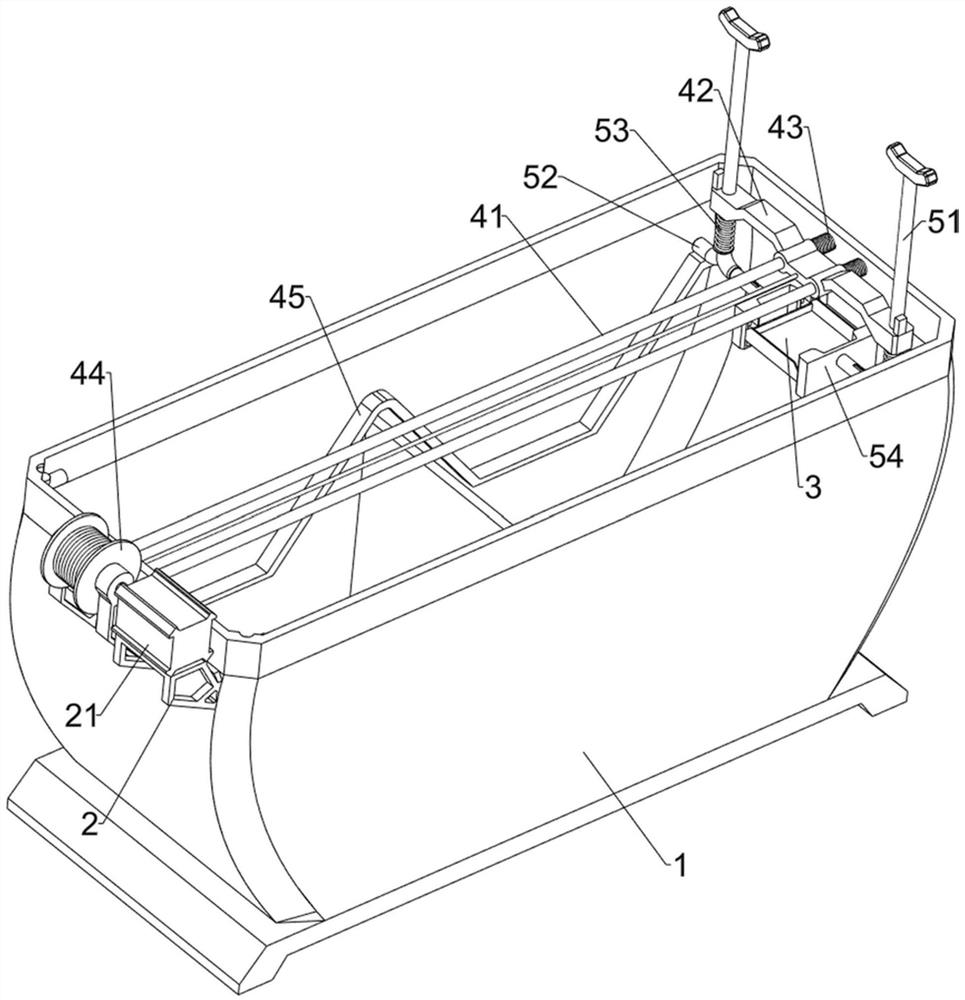

[0063] A kind of pickling equipment for surface rust prevention of copper alloy parts, such as Figure 1-Figure 4 , Figure 8 with Figure 9 As shown, it includes a charging box 1, a support frame 2, a servo motor 21, a placement tray 3, a moving assembly 4 and a pickling assembly 5. The upper left side of the outer wall of the charging box 1 is provided with a support frame 2, and the upper part of the support frame 2 is installed There is a servo motor 21, the upper part of the charging box 1 is provided with a moving assembly 4, the left side of the moving assembly 4 is connected to the output shaft of the servo motor 21, the lower side of the moving assembly 4 is slidingly provided with a pickling assembly 5, and the pickling assembly 5 slides The formula is provided with a placement tray 3.

[0064] When the worker needs to pickle the copper alloy, the worker can first put the copper alloy that needs to be pickled on the placement tray 3, and then the worker can turn on t...

Embodiment 2

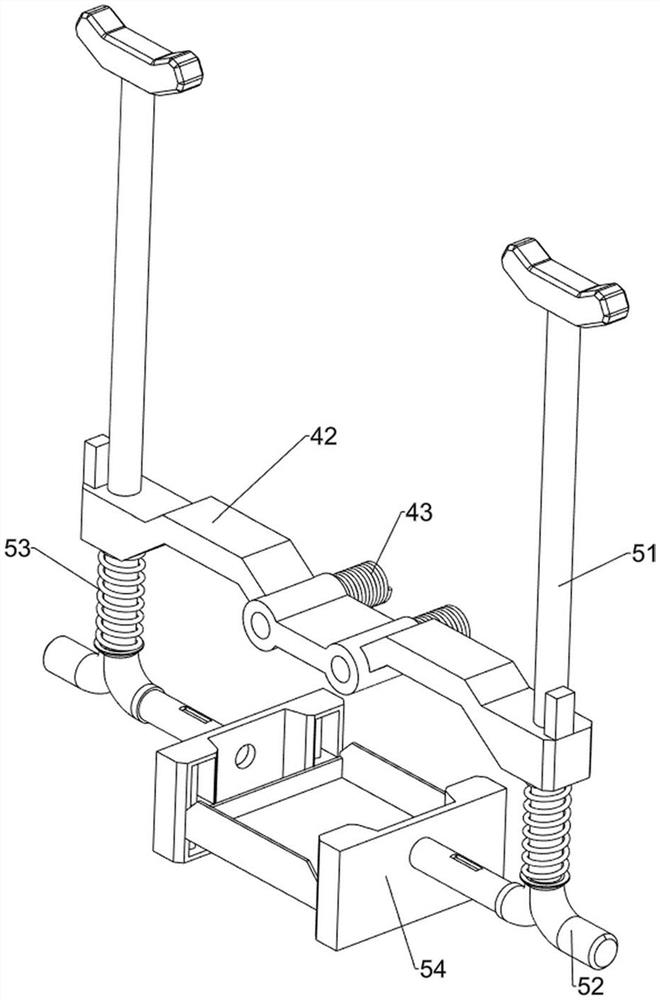

[0070] In a preferred embodiment of the present invention, as figure 1 and Figure 4-Figure 9 As shown, a guide assembly 6 is also included, and the guide assembly 6 includes a baffle plate 61, a second guide rail 62 and a torsion spring 63, and the front and rear sides of the upper inner wall of the charging box 1 are symmetrically provided with a second guide rail 62, and the two second guide rails 62 The left side is equipped with a baffle 61 which is rotated. The baffle 61 is in contact with the first guide rail 45. Two torsion springs 63 are set on the two second guide rails 62. The two ends of the torsion spring 63 are respectively connected to the baffle. 61 and the second rail 62.

[0071] When the T-shaped connecting rod 52 moves to the left to contact with the baffle plate 61, the T-shaped connecting rod 52 will cause the baffle plate 61 to rotate upwards on the second guide rail 62, so that the torsion spring 63 will be deformed, and then the baffle plate 61 will s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com