Rotary vacuum forming system for ceramic fibers

A ceramic fiber and vacuum forming technology, which is applied in the direction of inorganic fiber/sheet, textile and paper making, can solve the problems of unevenness and achieve the effect of avoiding waste, improving utilization rate and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

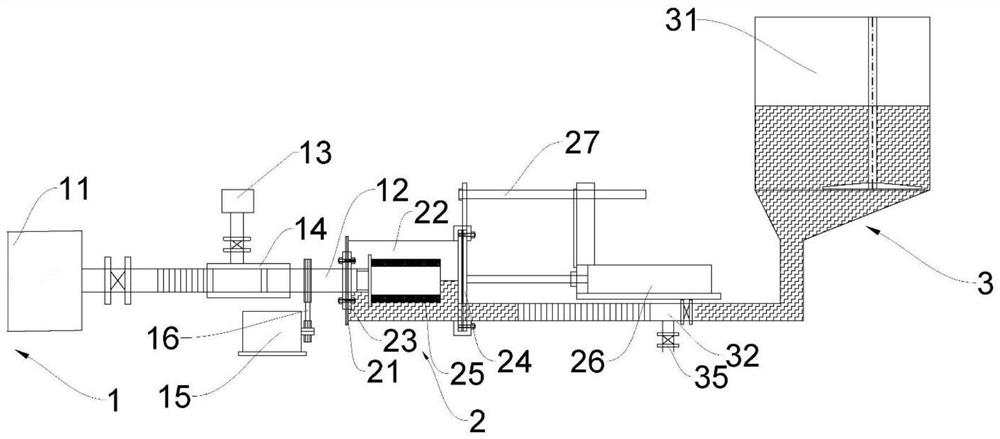

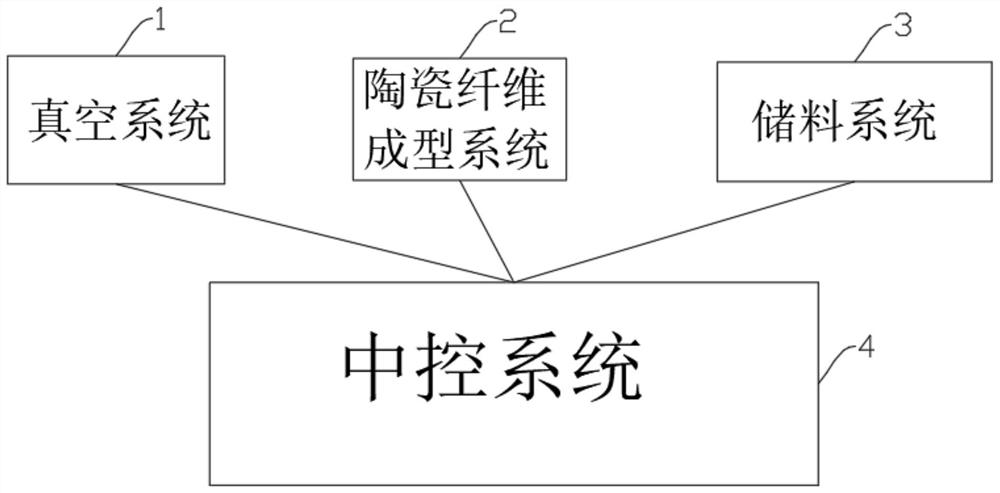

[0024] Such as figure 1 with figure 2 As shown, the present invention provides a ceramic fiber rotary vacuum forming system, including a vacuum system 1, the vacuum system 1 is connected with a ceramic fiber forming system 2, and the ceramic fiber forming system 2 is connected with a storage system 3, so The vacuum system 1, the ceramic fiber forming system 2 and the storage system 3 are respectively connected to a central control system 4.

[0025] By setting the vacuum system 1, the vacuuming of the ceramic fiber forming system 2 is realized, so as to suck out the moisture in the forming mold 25, and make the slurry adhere to the mesh of the forming mold 25, thereby forming ceramic fiber products , by setting the ceramic fiber forming system 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com