Multifunctional down-the-hole drill bit

A multi-functional, down-the-hole technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of slow impact drilling speed of down-the-hole hammer, unsuitable for silty soil, affecting construction progress, etc., and achieves a wide range of applications , Enhanced drilling ability and smooth drilling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

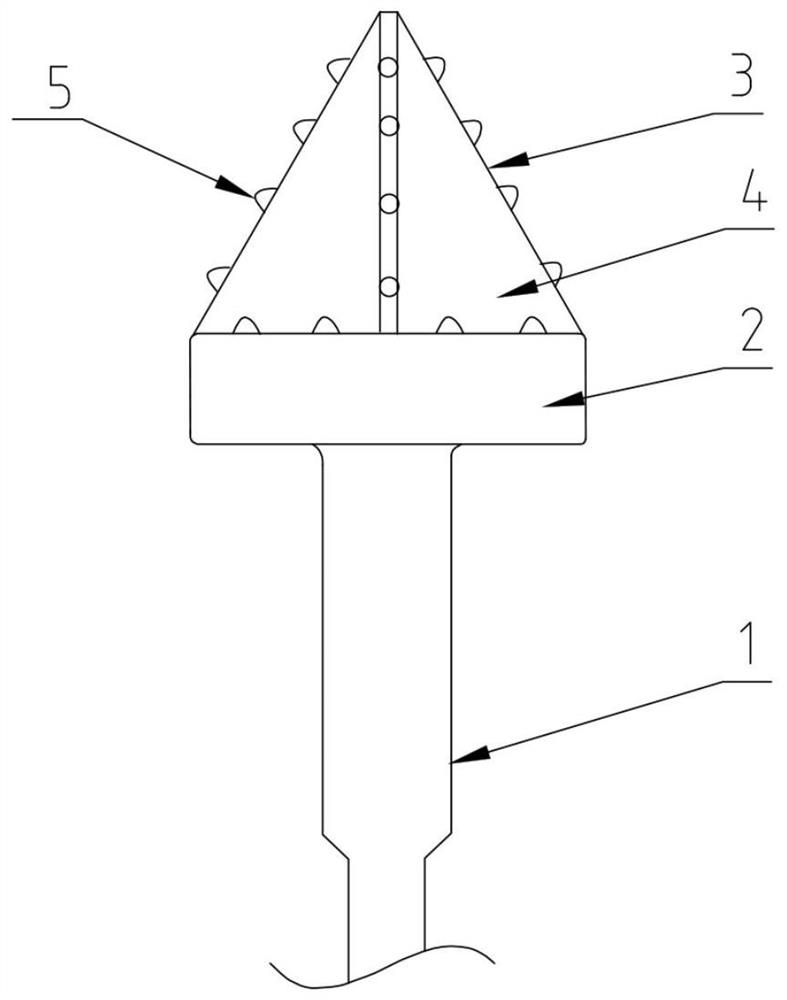

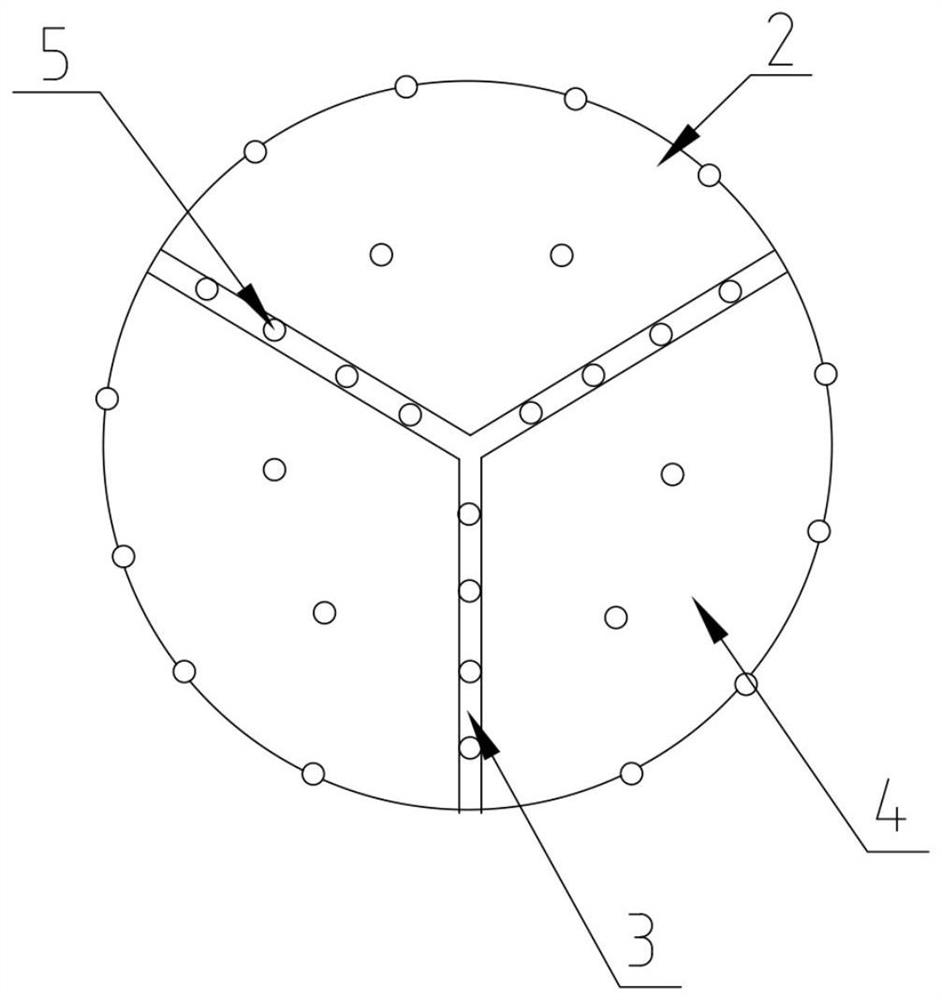

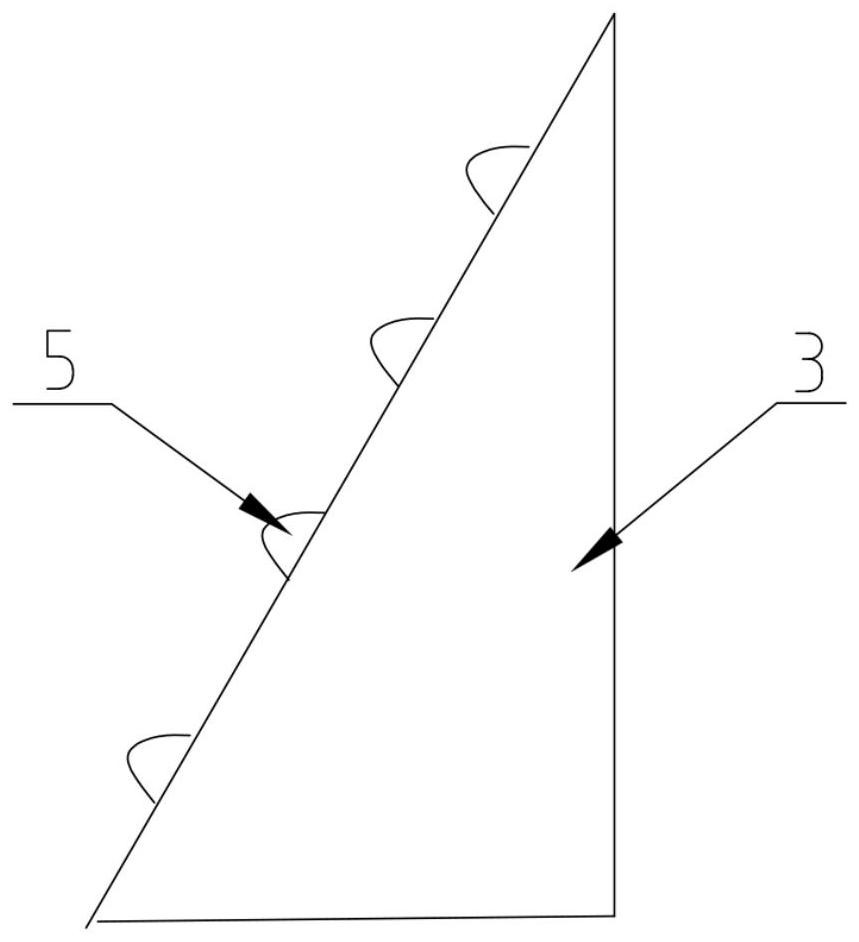

[0033] like Figure 1 to Figure 7 As shown, the present embodiment provides a multifunctional down-the-hole drill bit. The down-the-hole drill bit includes a drill rod 1 and a hammer head arranged at the front of the drill rod 1, wherein the hammer head includes a fixed base 2 with a circular top surface and a conical wing structure arranged on the top of the fixed base 2, The width of the bottom edge of the fin structure is 1-1.5 times the width of the top surface of the fixed base. The fin structure includes at least two fins 3 connected to each other. The angles between the fins 3 are equal to each other. The gap between the pieces 3 forms the first flute 4, and the shape of each wing 3 is a right triangle. The top surface of the fixed base 2 and the top of the wings 3 are respectively provided with button teeth 5, and are located on the fixed base 2. Each button 5 at the edge of the top surface partially protrudes from the fixed base 2 .

[0034] By adopting the above te...

Embodiment 2

[0036] On the basis of Example 1, the fin structure is further optimized. In this embodiment, the width of the bottom of the fin structure is preferably 1-1.2 times the width of the top surface of the fixed base 2 . More preferably, the width of the bottom edge of the fin structure is consistent with the width of the top surface of the fixed base 2, so that the transition between the fin structure and the fixed base 2 is smooth, so as to disperse the force and prevent the fin structure from being excessively stressed. The taper of the vane structure is 1:1-1:1.1, if the taper is greater than 1:1.1, the drilling resistance of the DTH bit in the silty soil layer will increase, which will reduce the drilling efficiency; if the taper is less than 1: 1, the width of the hammer head is not enough, which affects the hammer breaking ability of the hard soil layer.

Embodiment 3

[0038] In the present invention, the fin structure includes at least two interconnected fins 3 , for example, two, three, four, five and so on. Preferably, as figure 1 and 2 As shown, the fin structure includes three interconnected fins 3, the angle between the three fins is 120°, and the three fins 3 support each other to form a stable structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com