Brake bearing with high-friction braking effect and using method thereof

A technology with high braking effect and high friction, which is applied in the field of brake bearings, can solve the problems of small size and easy loss, and achieve the effects of convenient disassembly, improved precision and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

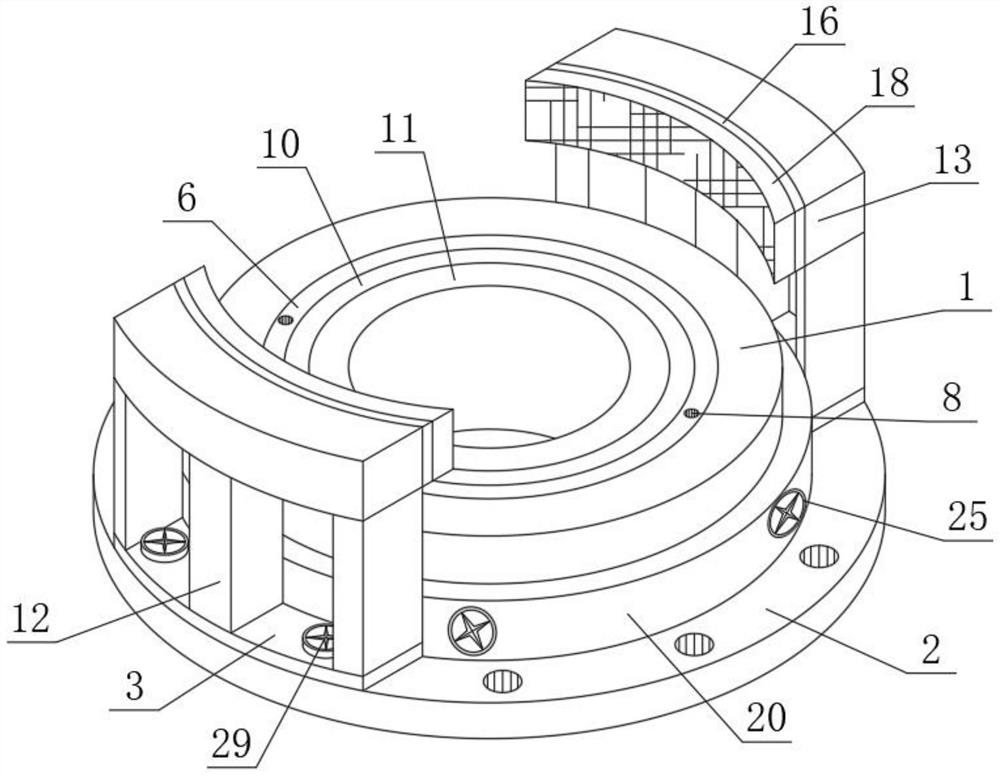

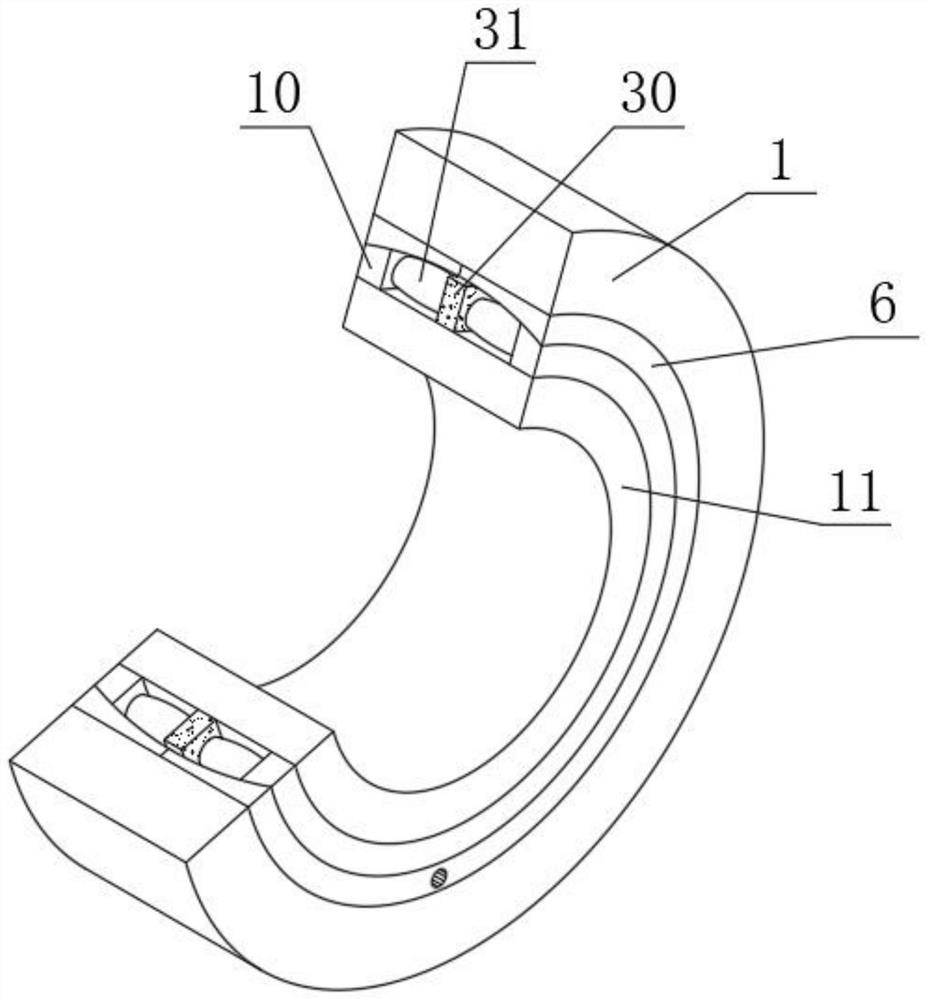

[0043] Such as figure 1 , figure 2 and image 3 As shown, a brake bearing with high frictional braking effect includes a bearing outer ring 1, a flange 2, a fixing plate 3 and a notch 4, the outer wall of the bearing outer ring 1 is installed with a flange 2, and the top of the flange 2 Two sets of fixed plates 3 arranged in left and right mirror images are installed;

[0044] Specifically, the bearing outer ring 1 can be used to connect other components in the brake bearing, and then facilitate the synthesis of a complete brake bearing between the components. It is convenient for the bearing outer ring 1 to be installed in other mechanisms. The fixing plate 3 is arc-shaped as a whole, which can be superimposed on the flange 2, and then the threaded nail 29 is used to penetrate the fixing plate 3 and the flange 2, and an external nut is used. Tighten the threaded nail 29, the fixed plate 3 can be firmly installed on the flange 2, and then each component on the fixed plate ...

Embodiment 2

[0050] Such as figure 1 and Figure 8 As shown, three groups of equidistantly arranged vertical blocks 12 are installed on the tops of the two groups of fixed plates 3, and the tops of the three groups of vertical blocks 12 are equipped with integrated blocks 13, and the inner walls of the integrated block 13 are provided with three groups of equidistantly arranged through grooves 14. , the inner walls of the three groups of through grooves 14 are equipped with electric telescopic rods 15, and one end of the three groups of electric telescopic rods 15 is equipped with arc-shaped plates 16.

[0051] Specifically, the vertical block 12 has a certain height, and the integrated block 13 can be lifted to a height beyond the position of the top of the bearing outer ring 1, and the three sets of vertical blocks 12 provide relatively stable support for the integrated block 13, increasing the installation of the integrated block 13. The combination block 13 is used to integrate the th...

Embodiment 3

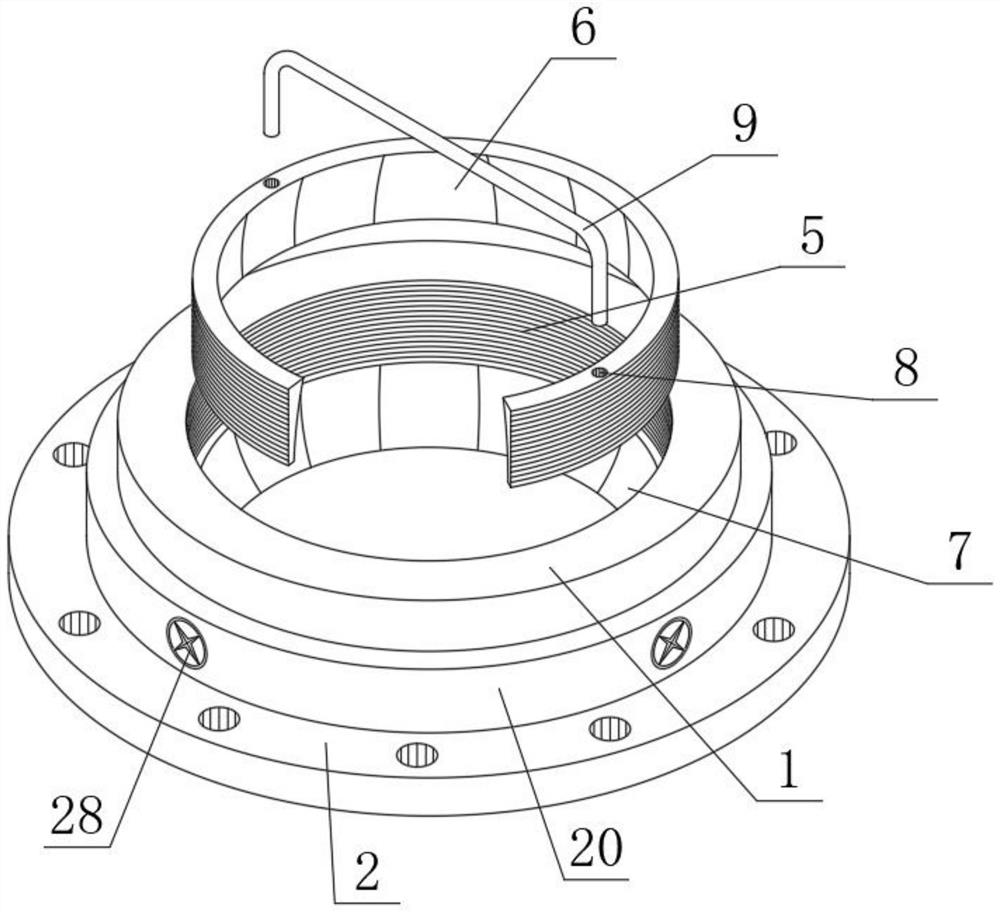

[0055] Such as Figure 4 , Figure 5 and Figure 6 As shown, an annular plate 20 is installed on the top of the flange 2, and the inner wall of the annular plate 20 is attached to the outer wall of the bearing outer ring 1. An extruding spring 22 is installed on the inner wall of the extruding spring 22, and a fixed ring 23 is installed on one end of the extruding spring 22.

[0056] Specifically, the annular plate 20 increases the connection between the flange 2 and the bearing outer ring 1, and at the same time, the fastening column 25 extending from the inside of the notch 4 can penetrate the inside of the thread groove 21, and then increases the connection between the flange 2 and the bearing outer ring. The firmness of the installation of the ring 1, wherein the extrusion spring 22 has a large elastic deformation capacity and reset function, when it is squeezed, it can shrink its own comprehensive length, and then drive the cylinder 24 and the fastening column 25 to shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com