Intelligent identification model for four-tube leakage of power plant boiler

An intelligent identification and boiler technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of difficult construction, high price, and inability to realize 24-hour continuous monitoring, so as to shorten maintenance time and reduce Scale, the effect of reducing inspection and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments.

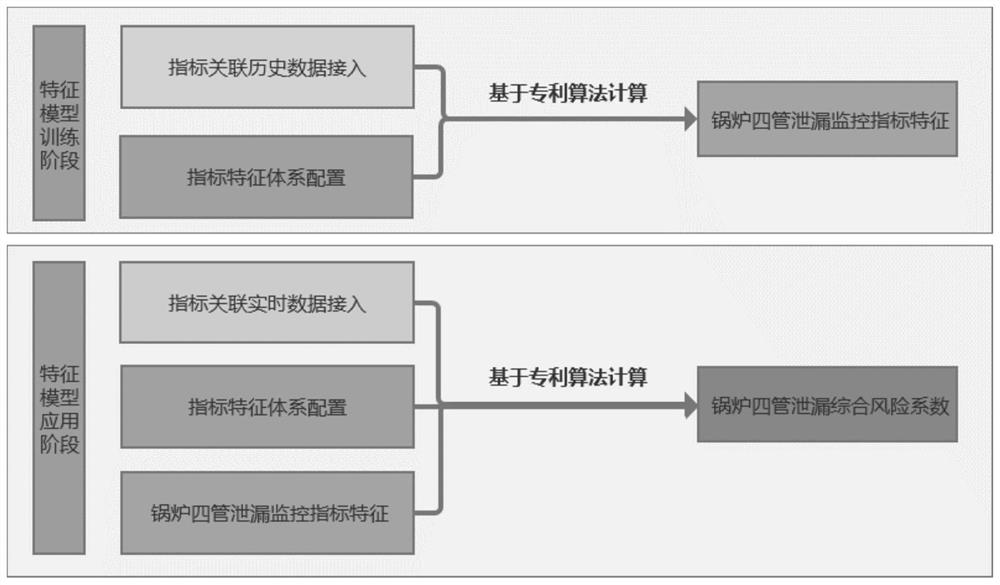

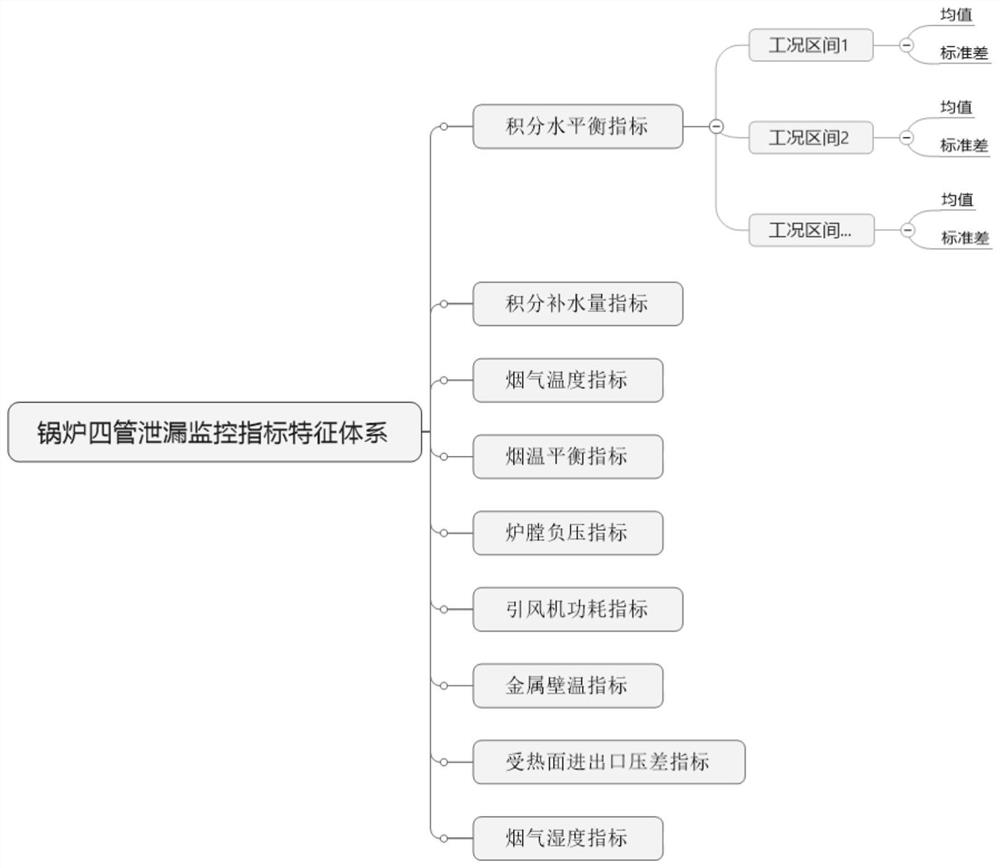

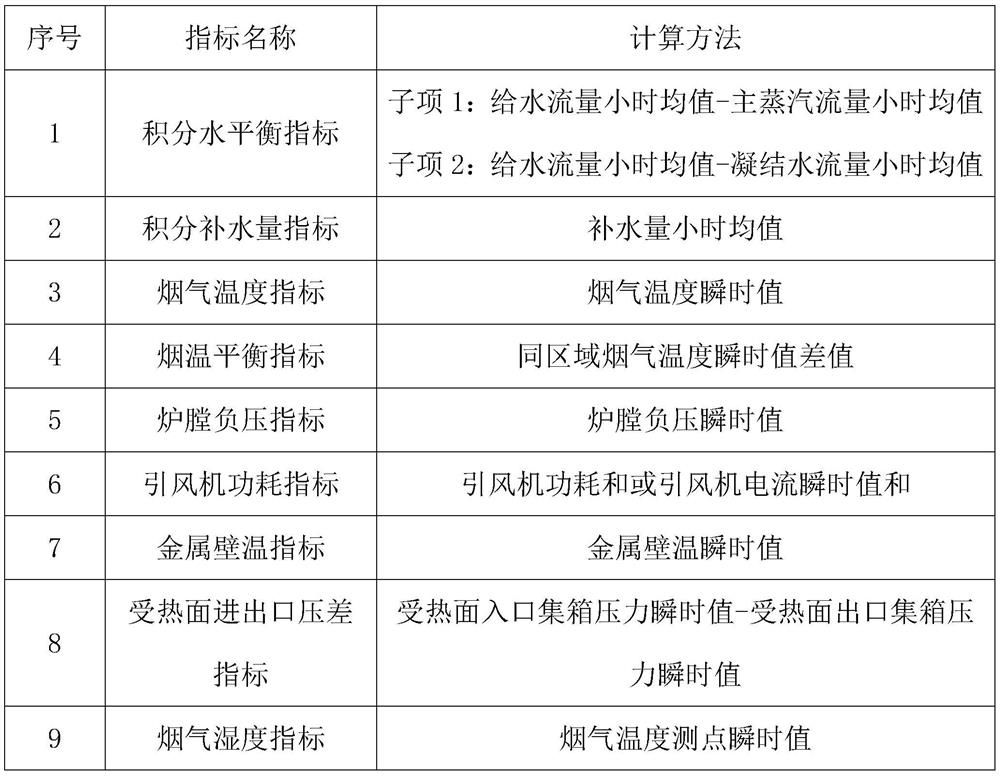

[0036] Please refer to figure 1 , figure 2 ,in, figure 1 A structural diagram of a preferred embodiment of the intelligent identification model provided by the electric plant boiler four tube leakage provided by the present invention; figure 2 for figure 1 The structural block diagram of the characteristics of the boiler four-tube leak monitoring indicator. Power plant boiler four-tube leak intelligent identification model includes the following steps:

[0037] S1: Establishment of the Situ Leakage Monitoring Index of Boiler;

[0038]S2: Establishment of the characteristics of the boiler four - tube leak monitoring

[0039] S3: Calculation of real - time risk factors of boiler four - tube leak monitoring indicators;

[0040] Calculation of the integrated risk factor in real time in the boiler four tube leakage.

[0041] Establishment of the boiler four-tube l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com