Assembly type anti-seismic anti-freezing-thawing deformation corrugated plate rigid-flexible retaining wall

A freeze-thaw-resistant, assembly-type technology, applied in protection devices, water conservancy projects, artificial islands, etc., can solve problems such as extrusion deformation damage, inability to adapt to permafrost areas, and retaining walls that do not have deformation adaptability to improve work Efficiency, the effect of reducing the force on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in combination with specific embodiments.

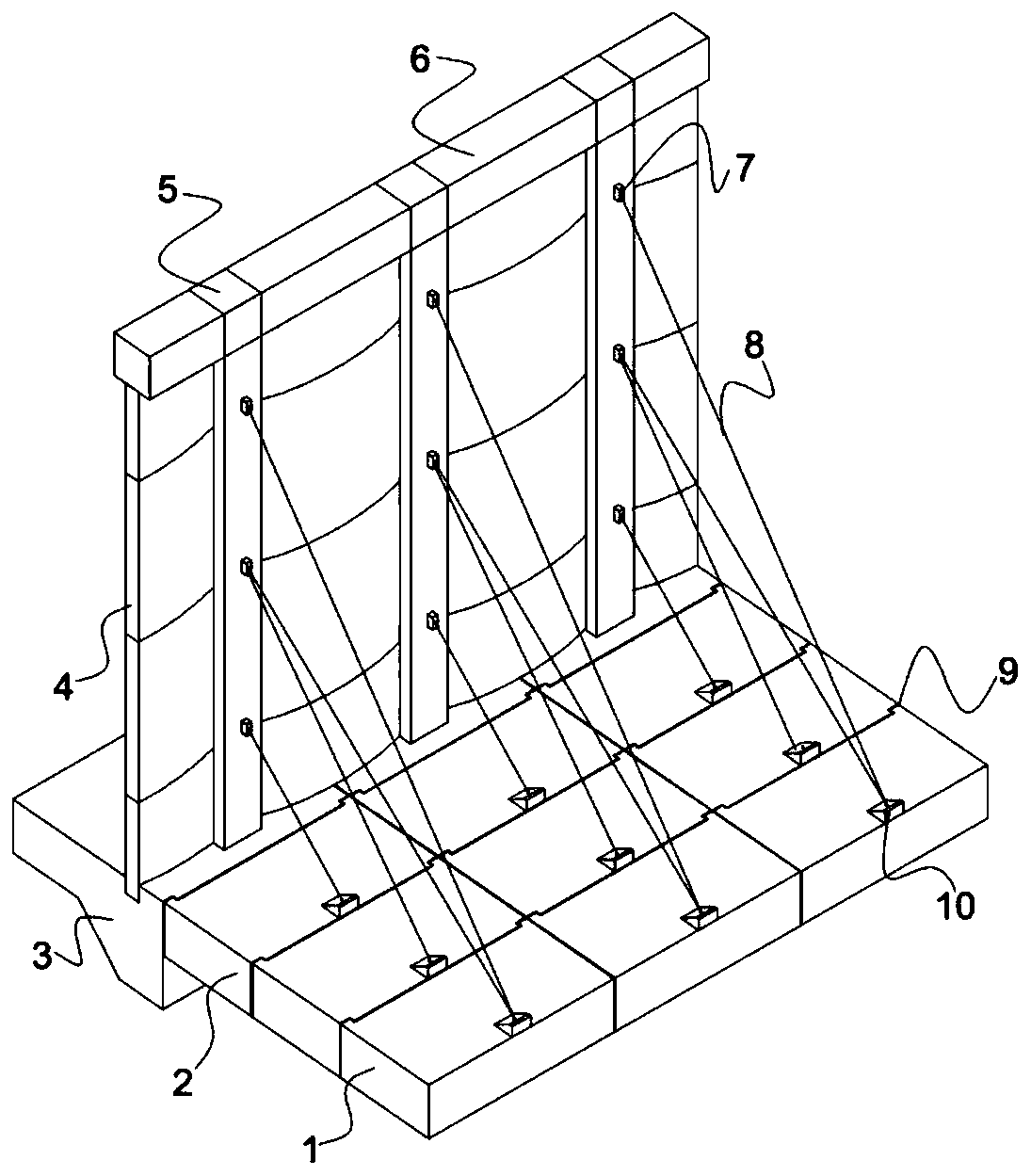

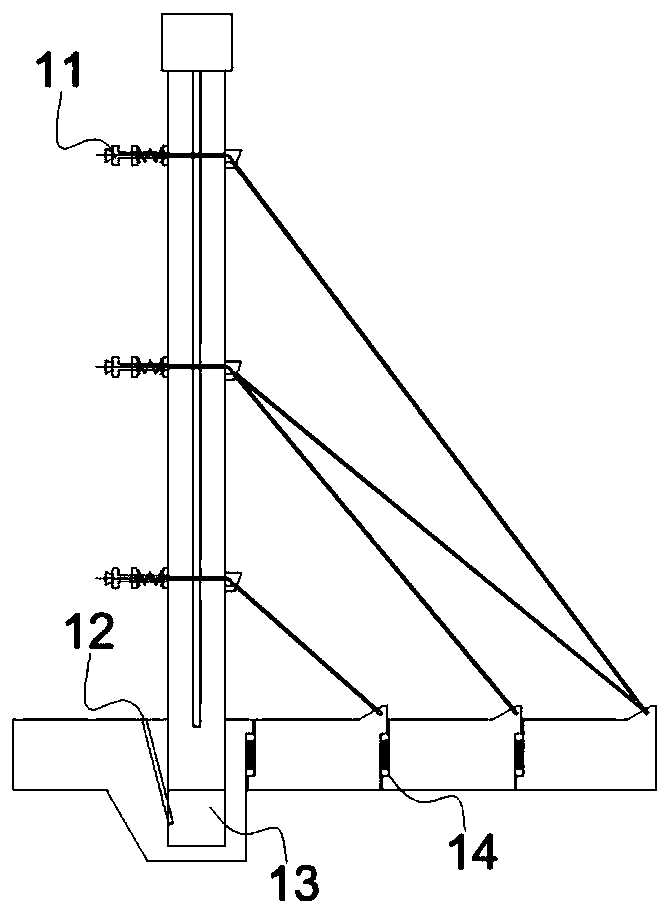

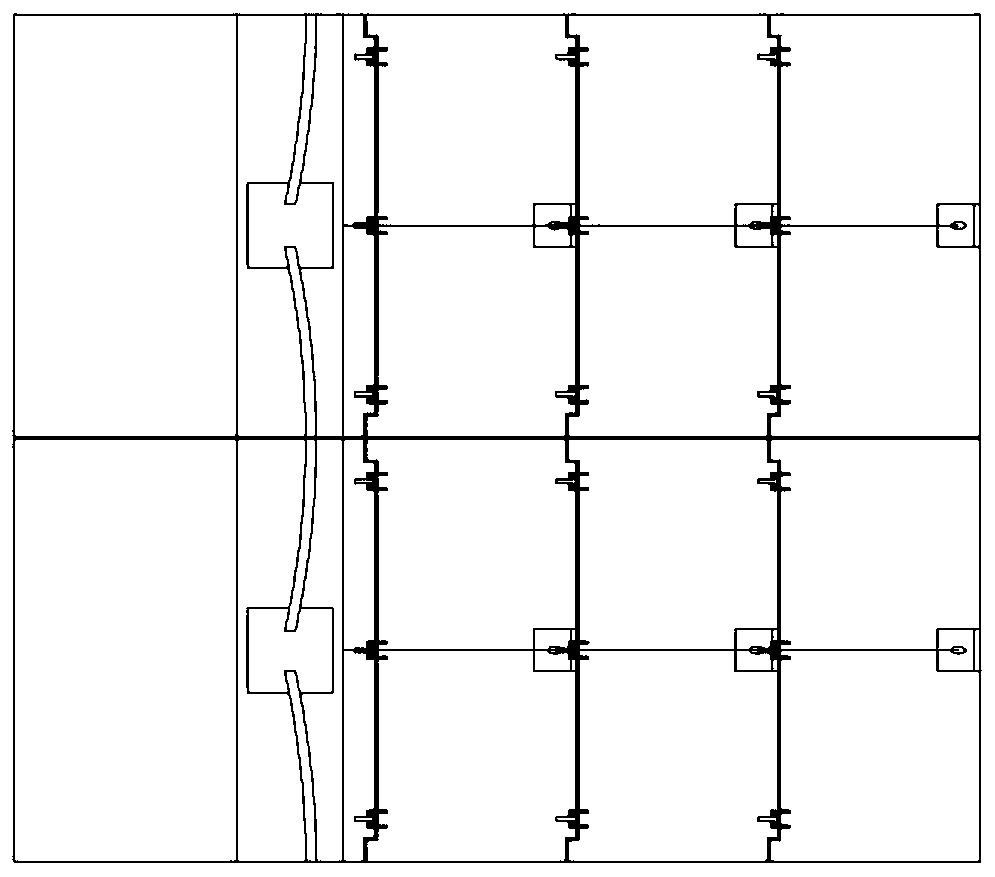

[0053] The invention relates to a prefabricated anti-seismic anti-freezing and anti-deformation corrugated plate rigid-flexible retaining wall, which has the ability to adapt to deformation and resist freezing and thawing and earthquakes. The bottom plate includes multiple rows of unit boards in the transverse direction. From the inside to the outside, there are front end bottom plate 1, middle connecting bottom plate 2 and basic bottom plate 3, which are assembled and connected by slots and inserts on the end faces. The earth retaining plate includes a plurality of uprights 5 and arched steel corrugated earth retaining boards 4 between the uprights 5. Strip grooves are arranged on the longitudinal sides of the uprights 5, and the ends of the arched steel corrugated earth retaining boards 4 are inserted into the uprights 5 in a strip shape. in the slot. The surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com