System for testing thermal deformation performance of aviation temperature sensitive element

A technology of sensitive components and test systems, applied in the direction of strength characteristics, the use of stable tension/pressure to test the strength of materials, measurement devices, etc., can solve the problems of low degree of automation, low measurement efficiency, difficulty, etc. Wide, easy to promote and apply, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

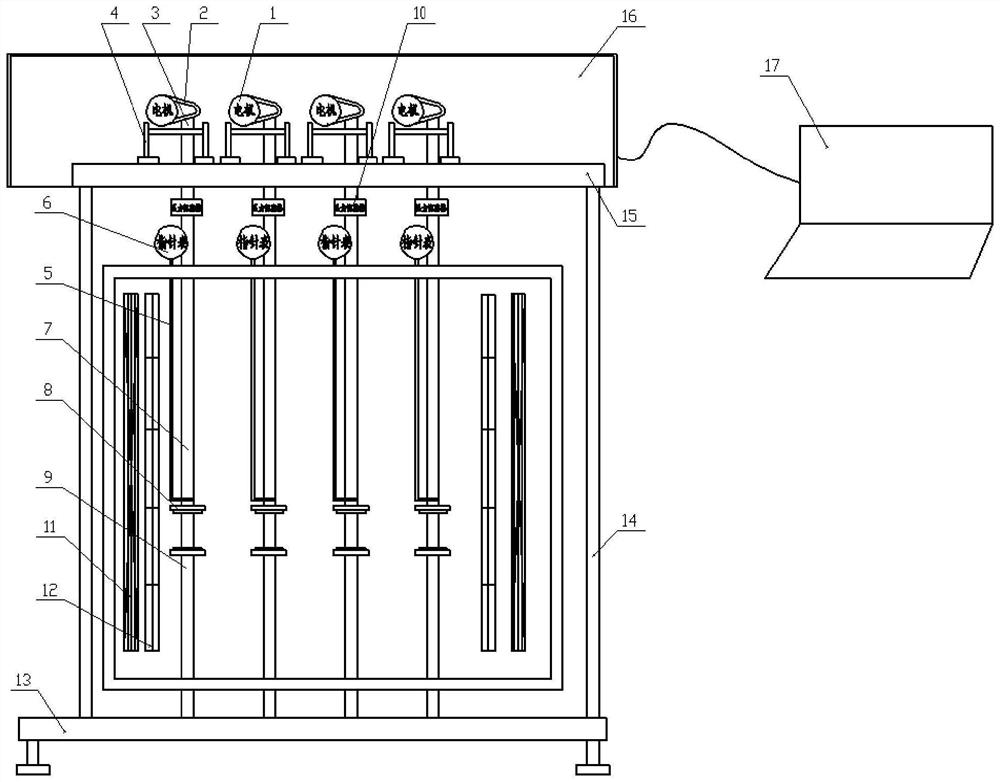

Method used

Image

Examples

Embodiment approach

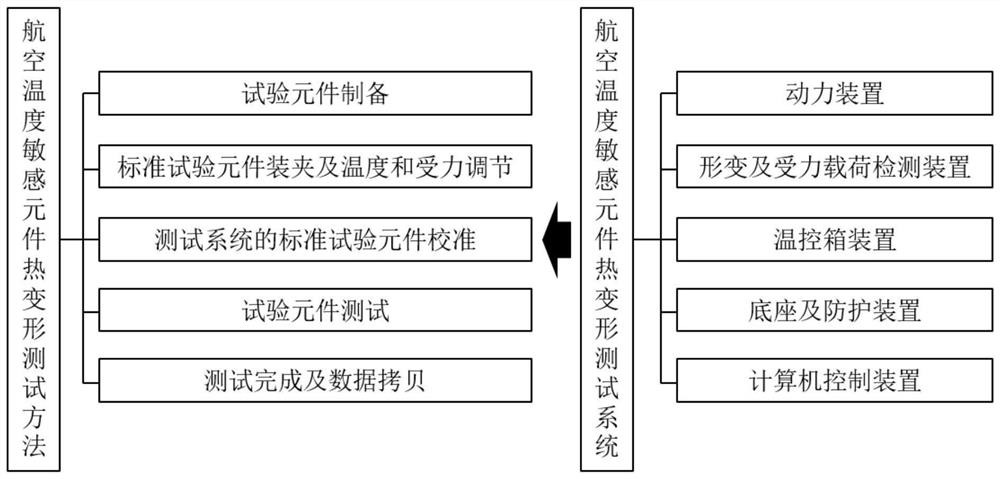

[0045] In other embodiments of the present application, a method for implementing thermal deformation performance testing of aviation temperature sensitive elements is provided, including the following steps:

[0046] S1. Test element preparation. Prepare the test elements according to the specifications and dimensions of the test elements.

[0047] S2. Standard test element clamping and temperature and force adjustment. Place the standard test element on the working surface of the fixture tooling in the temperature control box device, and use the computer control device to control and adjust the temperature and force load of the test element.

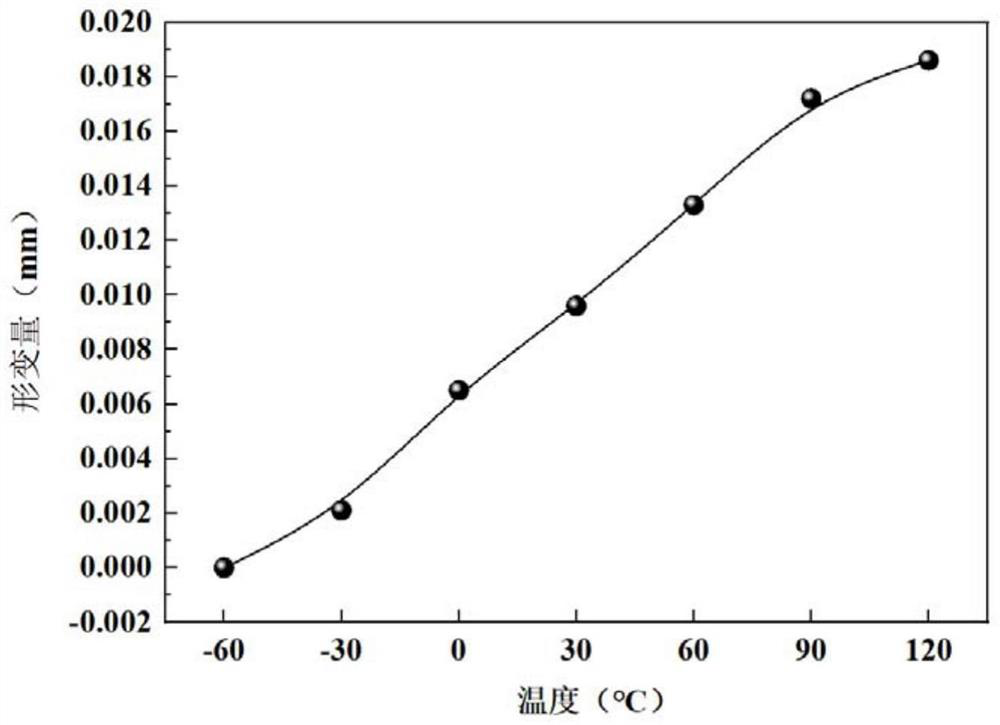

[0048] S3. Standard test element calibration of the test system. The computer control device is used to raise the temperature of the test components in the incubator device, and the temperature and deformation data of the standard test components are obtained through the deformation and force loading device, and compared with the dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com