Surface-mounted thin film capacitor and manufacturing method thereof

A technology of film capacitors and manufacturing methods, applied in the direction of film/thick film capacitors, laminated capacitors, fixed capacitor electrodes, etc., can solve the difficulty of meeting the needs of miniaturized circuit component integration, large volume of organic film capacitors, poor temperature resistance, etc. problem, to achieve the effect of small impedance, high fit and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

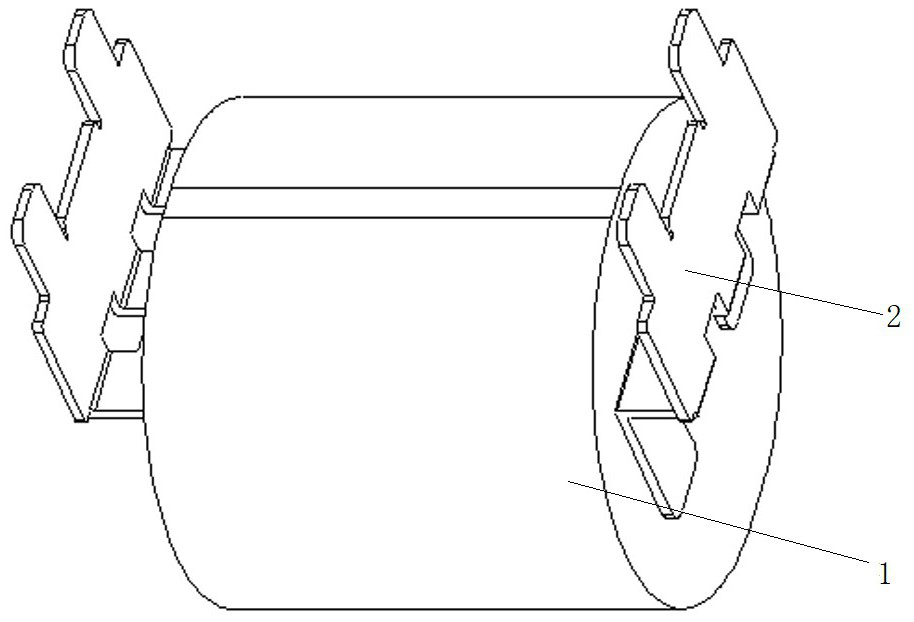

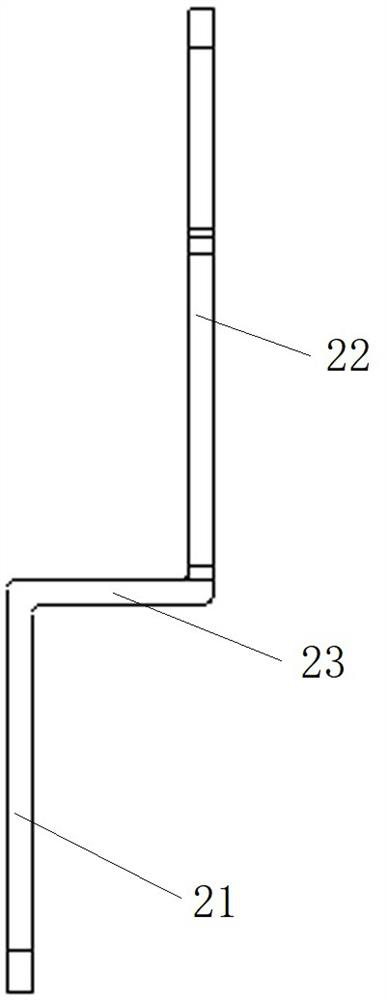

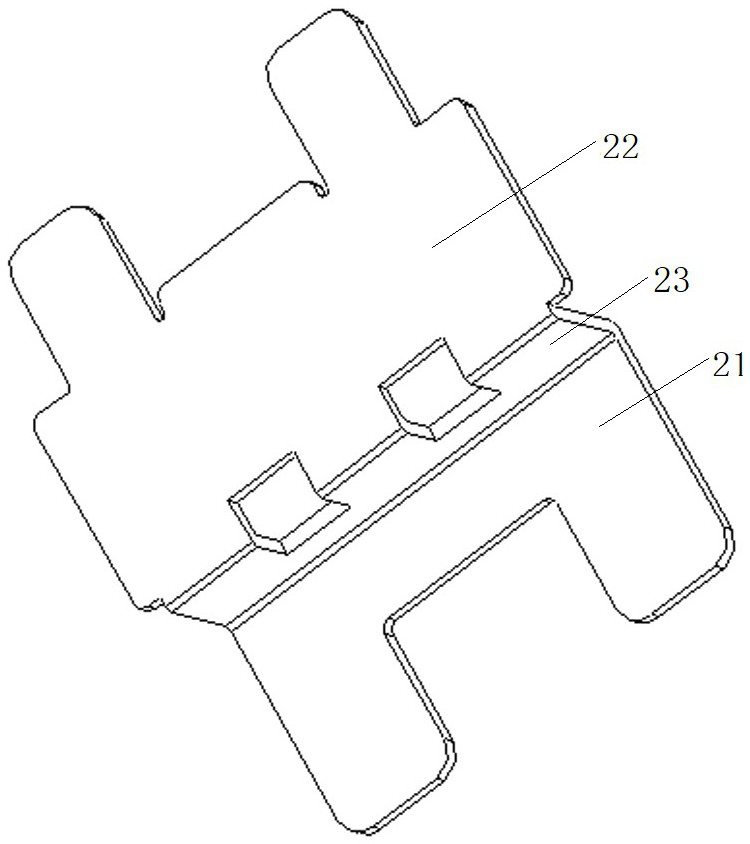

[0028] Such as Figure 1 to Figure 6 As shown, a film capacitor includes a capacitor core 1 with an elliptical end face. The two ends of the capacitor core 1 are respectively welded and connected with lead-out electrodes 2. The electrodes 2 are approximately Z-shaped, and the electrodes 2 are integrally formed. It includes an inner electrode surface 21 and an outer electrode surface 22, and the inner electrode surface 21 and the outer electrode surface 22 are connected by a connecting piece 23. The inner electrode surface 21 and the outer electrode surface 22 are respectively perpendicular to the connecting piece 23, and it also includes a square shell 3. The ends of the two outer surfaces of the shell 3 are provided with a notch 31, and the inside of the notch 31 is provided with a plug 311, and the two electrodes 2 are provided with a jack 24 that matches the plug 311, and the shell 3 is set on the The outer part of the capacitor core 1 is inserted into the insertion hole 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com