Recycling and reusing equipment and method for waste lithium ion battery cover plate

A lithium-ion battery, recycling technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of performance degradation, manual cleaning troubles, etc., to achieve convenient use of equipment, improve grinding effect, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

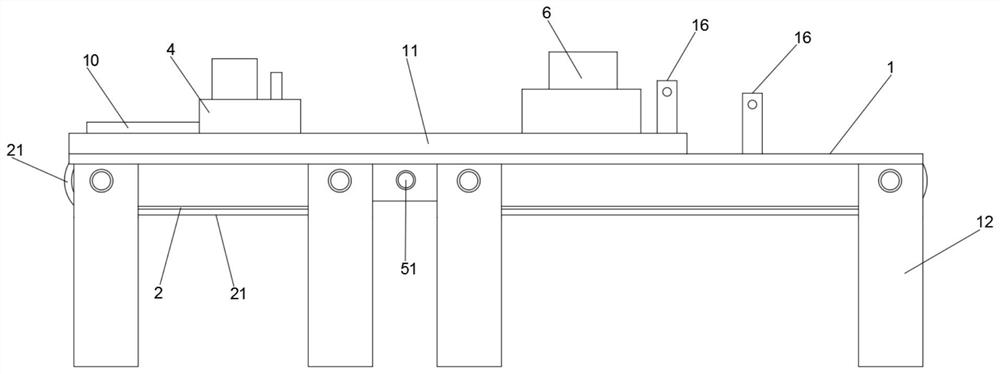

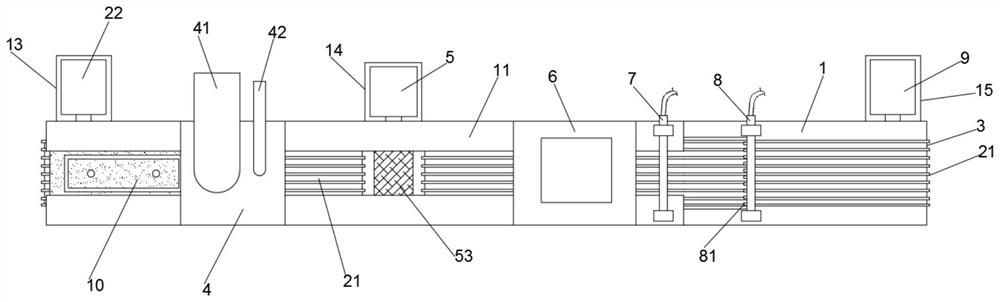

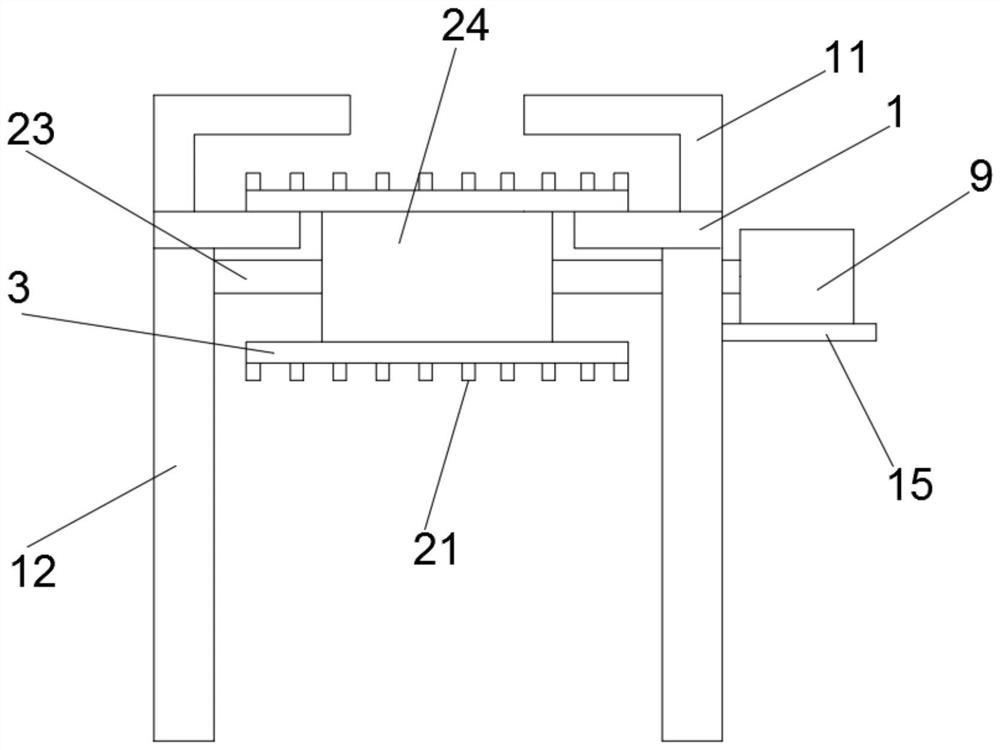

[0031] Such as Figure 1-5 As shown, the recovery and reuse equipment of the waste lithium ion battery cover plate 10 of the present invention includes a recovery platform 1, and the recovery platform 1 includes a transmission device, a front platform and a rear platform, and the front platform and the rear platform are connected by a transmission device. The bottom of the platform and the rear platform is equipped with supporting legs 12, and the conveying device includes the first conveyor belt 2 and the second conveyor belt 3, and the first conveyor belt 2 and the second conveyor belt 3 are installed on the supporting shaft by being installed on the supporting legs 12. Between the front platform and the rear platform, the first conveyor belt 2 is located on the left side of the second conveyor belt 3, and the support shaft includes a support rod 23 and a support column 24 arranged on the surface of the support rod 23, and the support column 24 is connected to the first conve...

Embodiment 2

[0034]As a further technical solution of the present invention, the supporting part 21 is preferably several elastic ribs arranged in parallel on the surface of the first conveyor belt 2 and the second conveyor belt 3, and the ribs are along the first conveyor belt 2 and the second conveyor belt 3 In addition, the support part 21 can also be replaced by elastic convex points and elastic triangular cones. The materials of elastic convex ribs, elastic convex points and elastic triangular cones are all rubber.

Embodiment 3

[0036] As a further technical solution of the present invention, a dust removal device is also installed on the upper surface of the clamping plate 11 at the first conveyor belt 2, and the dust removal device includes a dust removal box 4, an air knife 43 and a dust suction pipe 41, and the dust removal box 4 is fixedly installed on the On the clamping plate 11 on the front platform and the rear platform, the air knife 43 is fixedly installed on the top of the right side of the dust removal box 4, and the air outlet 44 of the air knife 43 is inclined to the left, and the dust suction pipe 41 is installed on the left side of the dust removal box 4. On the top of the side, the air knife 43 is connected with the external high-pressure air source through the air inlet pipe 42, and the dust suction pipe 41 is connected with an external vacuum cleaner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com