Friction material

A technology of friction materials and friction adjustment materials, which is applied to friction linings, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of wheel rust and brake noise, and has not been established to solve the problems of braking vibration, so as to achieve the purpose of suppressing braking vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

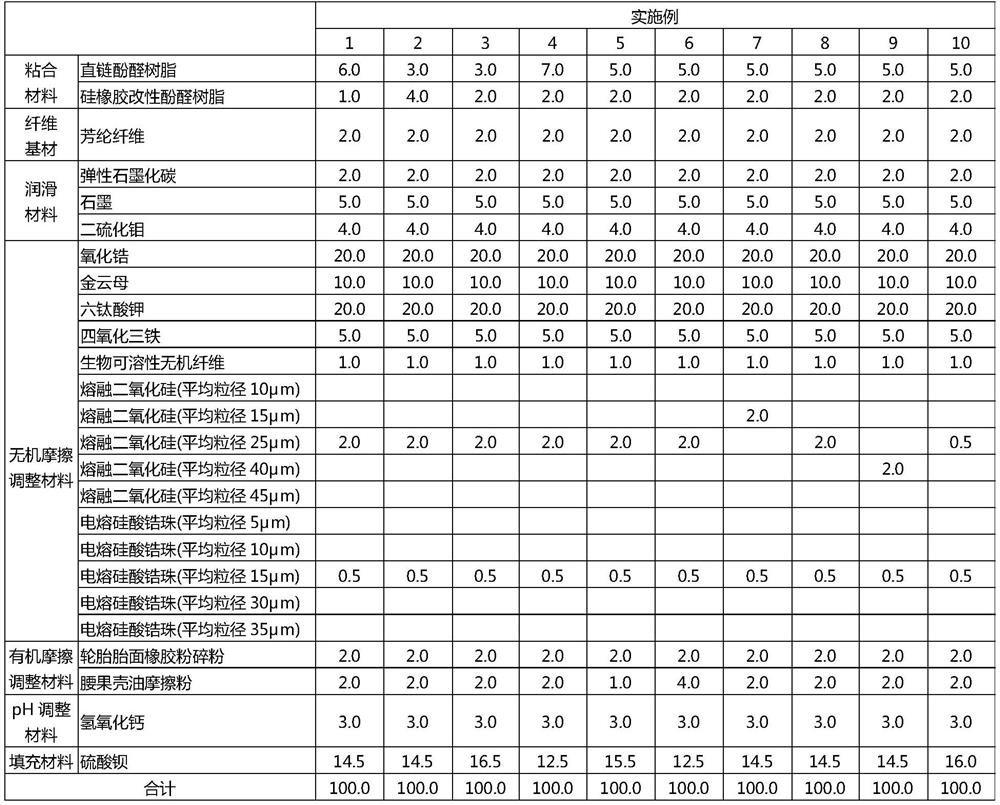

[0077] The present invention will be specifically described below by showing examples and comparative examples, but the present invention is not limited to the following examples.

[0078] [Methods of Manufacturing Friction Materials of Examples 1-19 and Comparative Examples 1-14]

[0079] use The mixer mixed the friction material compositions with the compositions shown in Table 1, Table 2, Table 3, and Table 4 for 5 minutes, and preliminarily molded them by applying a pressure of 30 MPa in a molding die for 10 seconds. The preliminary molded product was superimposed on the back plate made of steel that had been washed, surface treated, and coated with an adhesive material in advance, and was molded in a thermoforming mold at a molding temperature of 150°C and a molding pressure of 40MPa for 10 minutes. After molding, heat treatment (post-curing) was carried out at 200°C for 5 hours, and the friction surface was formed by grinding to produce disc brake pads for cars (Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com