Humidifying process method for reducing unpolished rice cracking in GABA rice production

A process method, brown rice technology, which is applied in grain processing, agriculture, application, etc., can solve the problems of waistline and seriousness, achieve uniform humidification, ensure hygiene, and facilitate subsequent germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

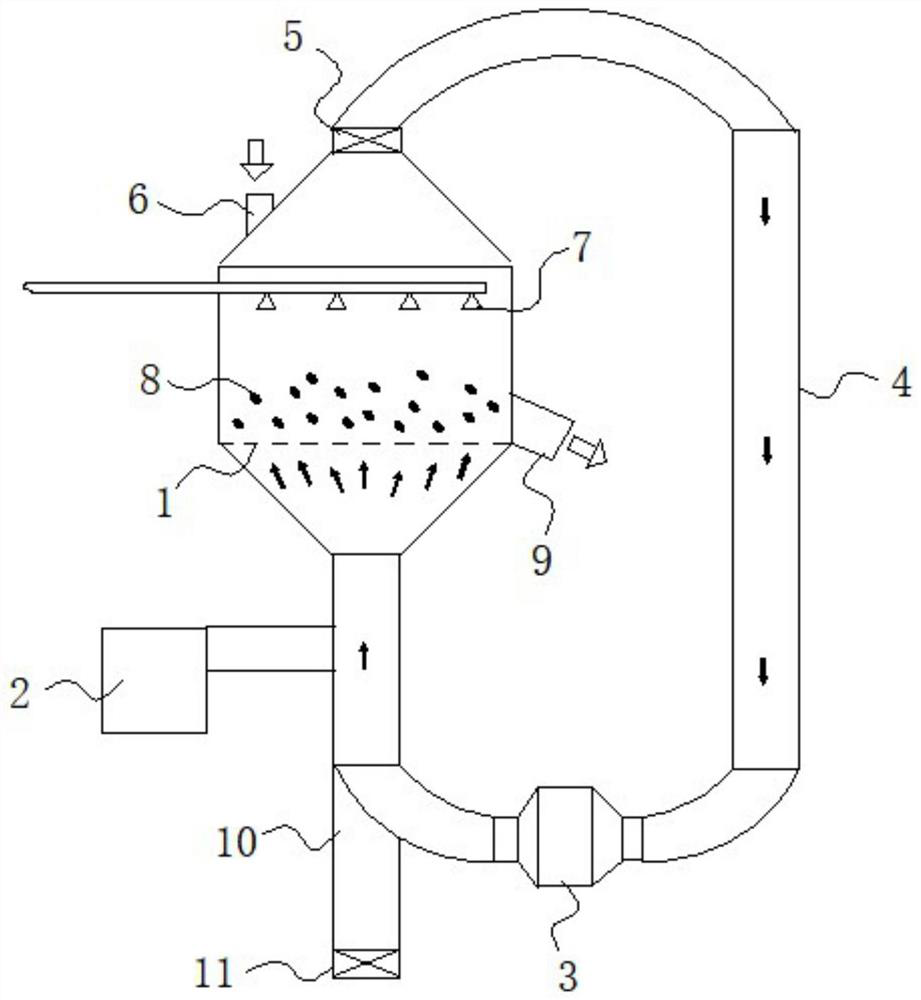

[0034] see figure 1 , in the present embodiment, brown rice water atomization humidification and spray humidification are all completed in a fluidized bed 1, and the fluidization of brown rice on the fluidized bed 1 is realized by the gas flow power generated by the blower 3. The present invention is a kind of humidification process method for reducing brown rice waist in the production of GABA rice, comprising the following steps:

[0035] The first step, carry out impurity cleaning and preliminary selection to raw material brown rice 8;

[0036] In the second step, the raw material brown rice 8 obtained in the first step is classified and selected;

[0037] The third step is to add the graded and selected raw material brown rice 8 into the fluidized bed 1 of a special device for humidifying brown rice, and carry out the water mist flow fluidized humidification treatment of the raw material brown rice 8, which specifically includes the following steps:

[0038] SS01 adds gr...

Embodiment 2

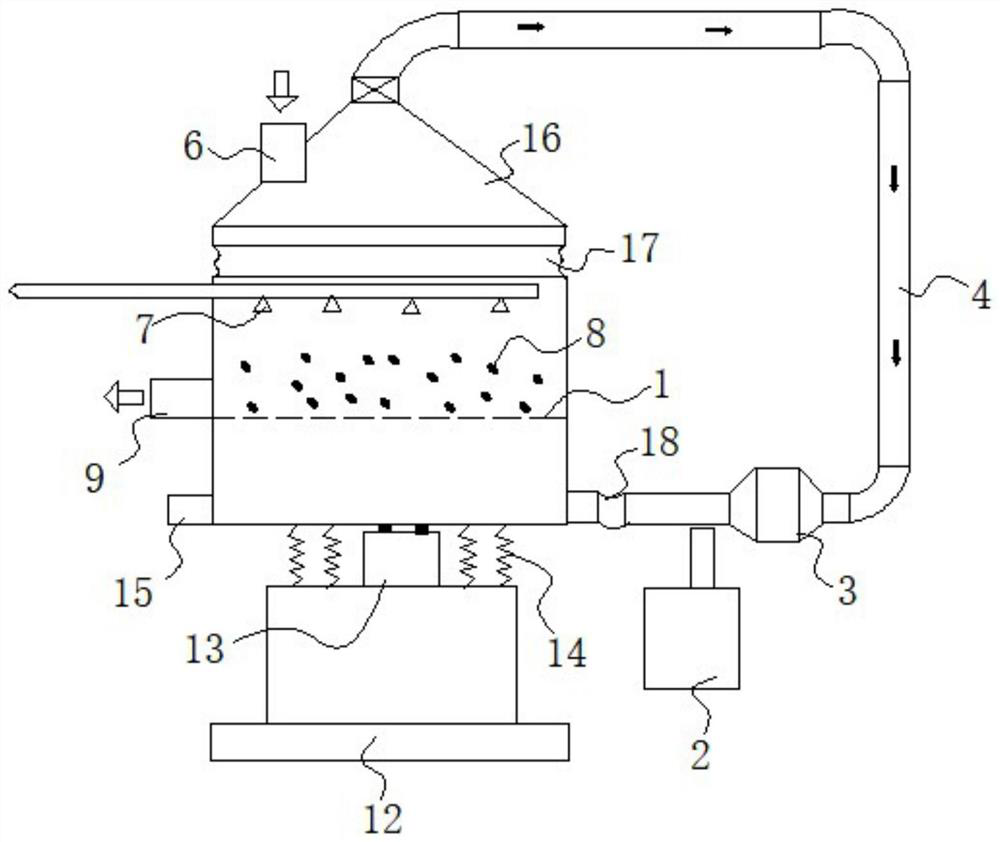

[0048] see figure 2 , in the present embodiment, brown rice water atomization humidification and spray humidification are all completed in a fluidized bed 1, and the fluidization of brown rice on the fluidized bed 1 is realized by the vibration generated by the vibrating motor 13. The present invention is a kind of humidification process method for reducing brown rice waist in the production of GABA rice, comprising the following steps:

[0049] The first step, carry out impurity cleaning and preliminary selection to raw material brown rice 8;

[0050] In the second step, the raw material brown rice 8 obtained in the first step is classified and selected;

[0051] The third step is to add the graded and selected raw material brown rice 8 into the fluidized bed 1 of a special device for humidifying brown rice, and carry out the water mist flow fluidized humidification treatment of the raw material brown rice 8, which specifically includes the following steps:

[0052] SS01 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com