Method for rolling rods and wires through negative tolerance

A bar and wire rod and negative tolerance technology, applied in the field of negative tolerance rolling rod and wire rod, can solve the problem of not considering the influence of material production, and achieve the effect of promoting enterprise sales and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Roll a batch of 1000 tons of steel bars with a diameter of 6-12mm and a length of 6m. The 600 tons of steel bars are transported to Nanjing City, Jiangsu Province at a temperature of 30°C, and 400 tons of steel bars are transported to the Daxinganling area of Heilongjiang Province at a temperature of -40°C. Central District.

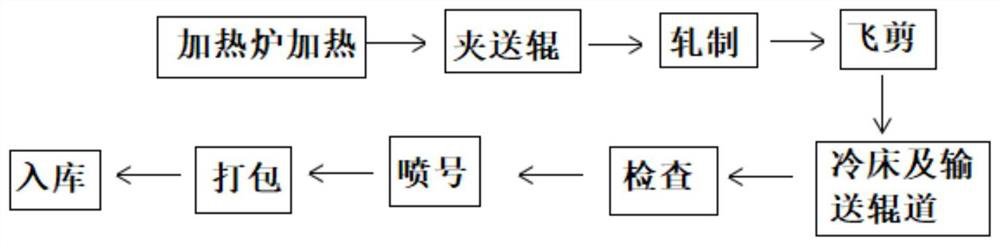

[0026] Such as figure 1 As shown, the method for rolling rods and wires with negative tolerance, the steps include:

[0027] Step 1. Put the steel into the heating furnace for heat treatment of preheating, heating and soaking, specifically:

[0028] 1.1. Preheating section: preheat for 10 minutes at a temperature of 300°C;

[0029] 1.2. Heating section: continue to raise the temperature to 1100°C for 20 minutes;

[0030] 1.3. Soaking section: continue soaking at a temperature of 900°C for 10 minutes;

[0031] Step 2. Roll the steel after the heat treatment in step 1 through pinch rollers to become steel bars to be cut; the rolling bending fo...

Embodiment 2

[0043] Roll a batch of 1000 tons of steel bars with a diameter of 14-20mm and a length of 9m. The 700 tons of steel bars are transported to Guangzhou City, Guangdong Province at a temperature of 40°C, and the 300 tons of steel bars are transported to Changchun City of Jilin Province at a temperature of -20°C.

[0044] Such as figure 1 As shown, the method for rolling rods and wires with negative tolerance, the steps include:

[0045] Step 1. Put the steel into the heating furnace for heat treatment of preheating, heating and soaking, specifically:

[0046] 1.1. Preheating section: preheat for 13 minutes at a temperature of 350°C;

[0047] 1.2. Heating section: continue to raise the temperature to 1150°C for 25 minutes;

[0048] 1.3. Soaking section: continue soaking at 950°C for 15 minutes;

[0049] Step 2. Roll the steel after the heat treatment in step 1 through the pinch rollers to become the steel bars to be cut; the rolling bending force is set to 1900KN, and the steel b...

Embodiment 3

[0061] A batch of 1,000 tons of steel bars with a diameter of 22-25mm and a length of 12mm were rolled. The 550 tons of steel bars were transported to Dubai at a temperature of 50°C, and the 450 tons of steel bars were transported to Shenyang City, Liaoning Province at a temperature of 0°C.

[0062] Such as figure 1 As shown, the method for rolling rods and wires with negative tolerance, the steps include:

[0063] Step 1. Put the steel into the heating furnace for heat treatment of preheating, heating and soaking, specifically:

[0064] 1.1. Preheating section: preheat for 15 minutes at a temperature of 400°C;

[0065] 1.2. Heating section: continue to raise the temperature to 1200°C for 30 minutes;

[0066] 1.3. Soaking section: continue soaking at 1000°C for 20 minutes;

[0067] Step 2. Roll the steel after the heat treatment in step 1 through the pinch rollers to become the steel bar to be cut; the rolling bending force is set to 2800KN, and the steel bar to be cut afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com