Method for joint production of capacitive carbon and high-purity cellulose

A technology of joint production and cellulose, applied in the field of material science, can solve the problems of complex source of papermaking raw materials, high ash content, and complex composition of alkali lignin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

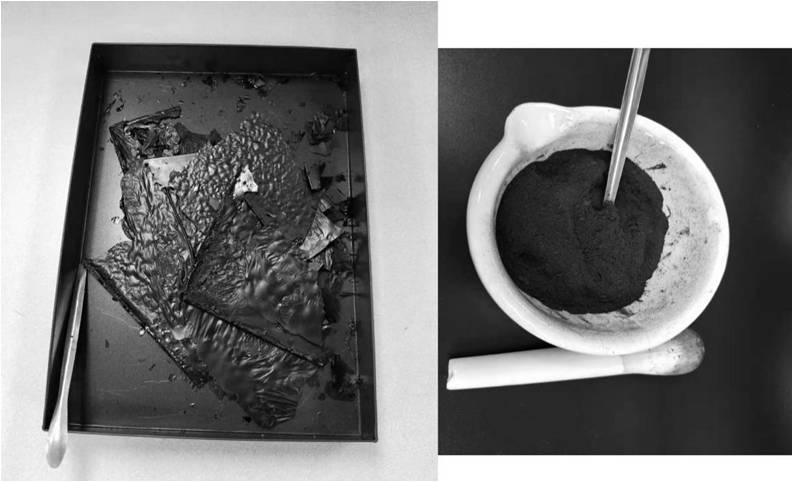

Image

Examples

Embodiment 1

[0103] With the bagsee of the Guangxi Rural Reclamation Bureau Mingyang Paper Plant, the potassium hydroxide (KOH) is extracted with alkaline lumen reagents, potassium carbonate (K 2 CO 3 The alkaline salt activator of the capacitor carbon, the urea is a token, indicating the specific operation steps and results of the first embodiment. KOH is more expensive than NaOH, but as the active agent is much better than NaOH, because the capacitor carbon is a high value product, the activator can be recovered, so the KOH pulping is calculated. Most of KOH in the pulping process has been converted to K 2 CO 3 , Truly activation is k 2 CO 3 .

[0104] (1) Subsence of the base separation

[0105] With the bagsee of the Guangxi Rural Reclamation Bureau Mingyang Paper Plant, the powder and debris are sieved, weigh 100 grams of 500 ml of tapered flask, add 500 g of KOH solution (including 20 grams KOH), The gauze is heated in a 125oC oven for 10 hours, and the water is added 4 times. After remo...

Embodiment 2

[0127] Mill bagasse pith is separated from the bagasse was not waste paper, accounting for about 35% of the bagasse pith short fibers in powder form, not paper, it is usually discarded as waste. In the present embodiment pith as raw material, sodium hydroxide (NaOH) to extract lignin alkali agent, sodium carbonate (Na 2 CO 3 ) Salts of alkaline activators capacitor carbon, urea as co-activator, specific procedures and results of Example 2. Cheaper than NaOH KOH, is commonly used in pulping agent, a base in the cooking and pith lignin carbonization converted mainly Na 2 CO 3 , Can also act as a basic salt activator.

[0128] (1) Alkaline separated pith

[0129] Yang Ming Guangxi Bureau of Reclamation pith mill waste as raw material, wherein the screening and debris powder, weighed 100 g pith short fibers placed in a 2000ml Erlenmeyer flask, 500 g of 4% NaOH solution ( containing 20 g of NaOH), yarn inlet Bouza heated oven at 125ºC for 10 hours, water was added intermediate 4, taken...

Embodiment 3

[0151] In the first embodiment two embodiments, to a base KOH and NaOH as separate lignin and cellulose reagent to K 2 CO 3 Na 2 CO 3 As basic salts capacitance carbon activator, and finally recovering the K 2 CO 3 Na 2 CO 3 . This embodiment with K 2 CO 3 Both as lignin - cellulose separating agent, and as an alkaline salt activator capacitor carbon, K is finally recovered 2 CO 3 Full cycle, separation agents may be salts of alkali activator and reuse.

[0152] (1) Alkaline separating bagasse

[0153] In pith Yang Ming Guangxi Bureau of Reclamation paper mill as a raw material, wherein the screening and debris powder, weighed 100 g placed in a 2000ml Erlenmeyer flask, 500 g of 4% K 2 CO 3 Solution (containing 20 g of K 2 CO 3 ), Yarn inlet Bouza heated oven at 125ºC for 10 hours, water was added intermediate 4, taken after centrifugation, the filtrate is the base for extracting lignin, cellulose residues for purification.

[0154] Extraction (2) an alkali lignin

[0155] The alka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com