Waste recovery device for stainless steel shot production

A technology of scrap recycling and stainless steel, applied in the field of scrap recycling devices for stainless steel shot production, can solve the problems of steel shot quality, large explosion range, inconvenient centralized recycling, etc., and achieve the effect of preventing unqualified quality and accelerating recycling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

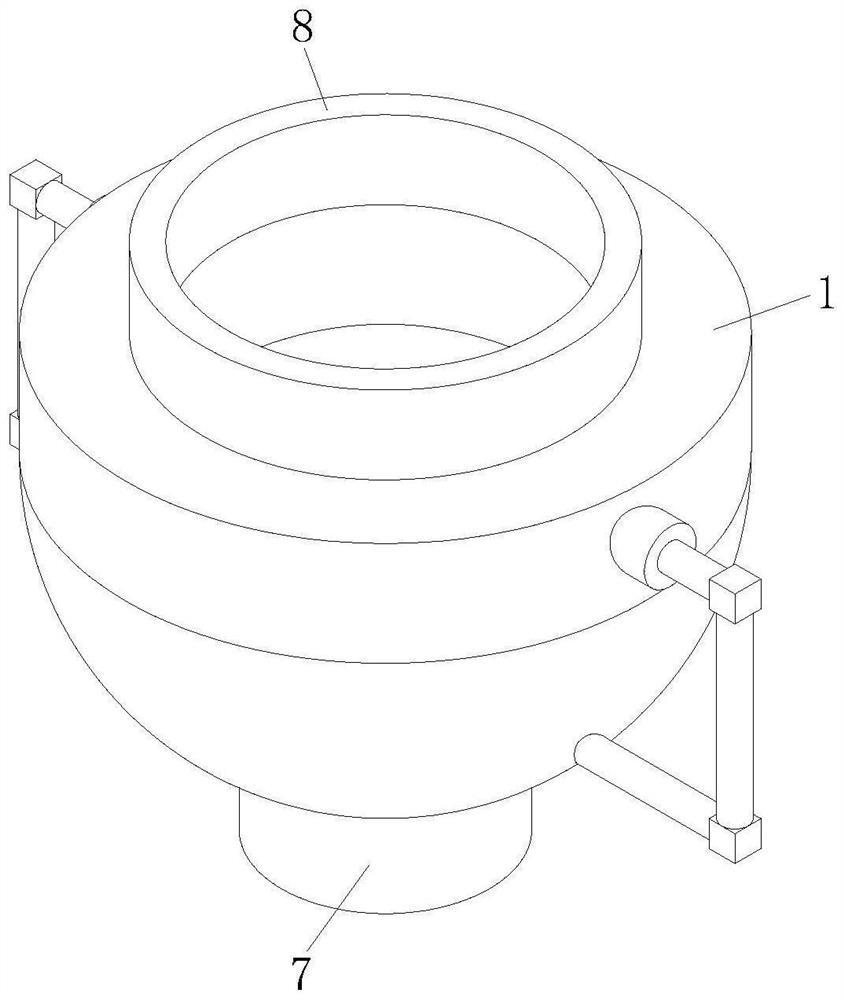

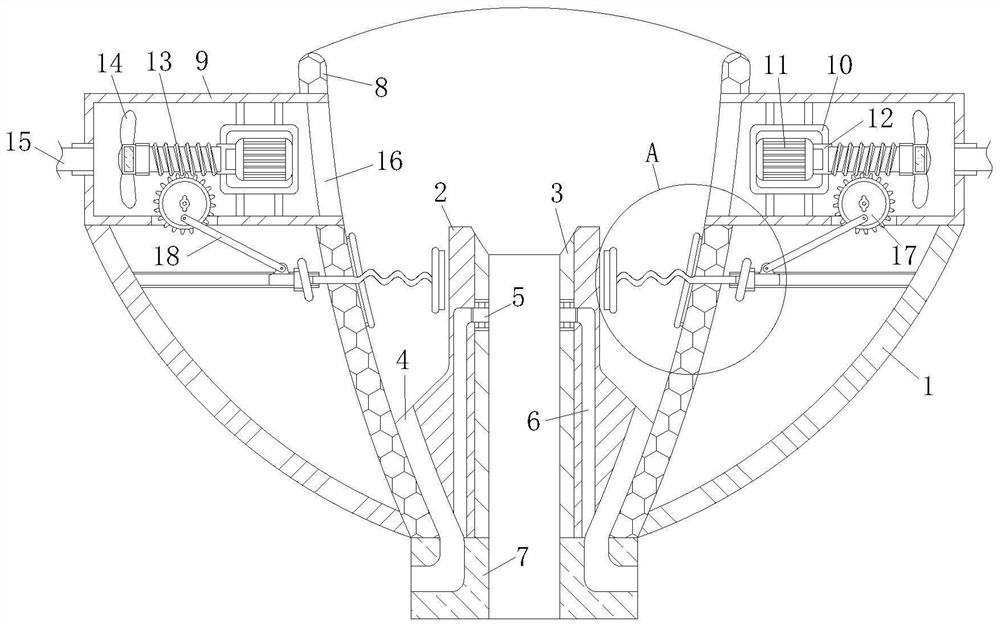

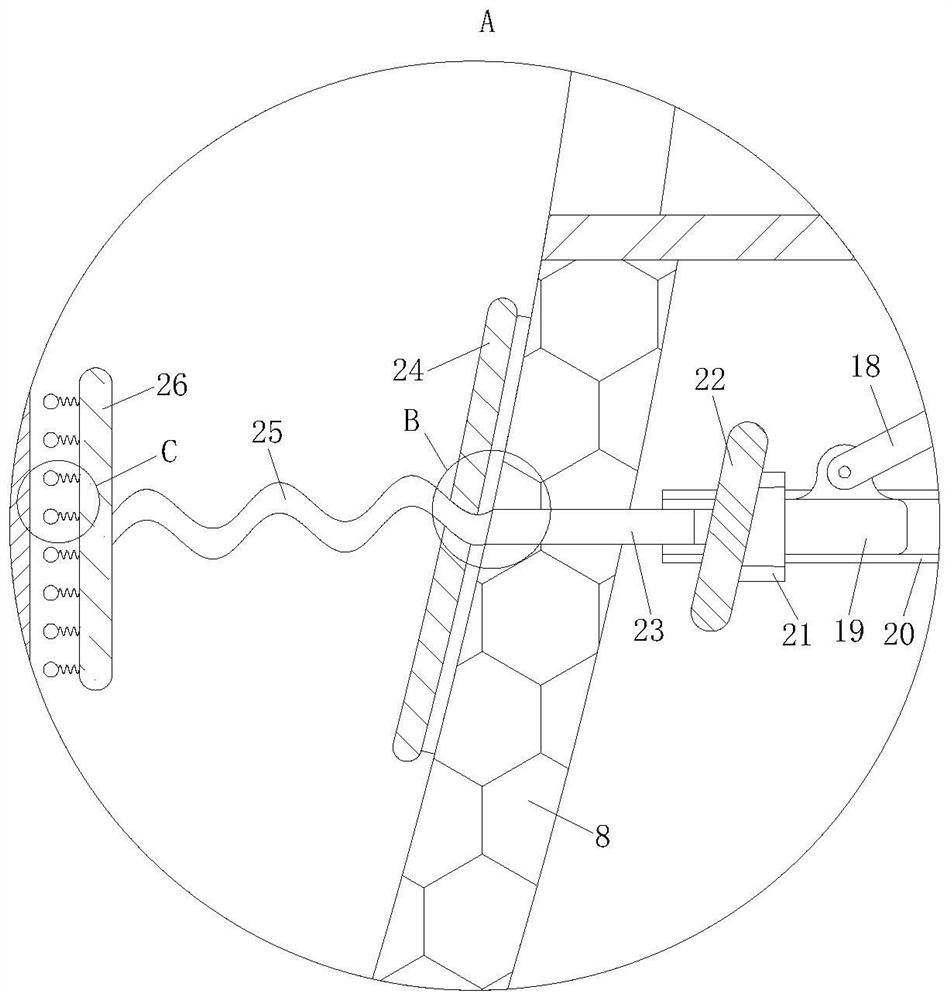

[0028] like Figure 1 to Figure 2As shown, a waste recycling device for stainless steel shot production according to the embodiment of the present invention includes a protective shell 1, a receiving plate 8 is fixed inside the protective shell 1, and a guide plate 2 is fixed inside the receiving plate 8 , the inside of the guide plate 2 is fixed with a blanking tube 3, the recovery tube 4 is fixed between the guide plate 2 and the receiving plate 8, the bottom end of the protective shell 1 is fixed with a mounting frame 7, and the mounting frame 7 There is a recovery hole connected to the recovery pipe 4 inside, and a suction shell 9 is fixed on the top of the protective shell 1, and the suction shell 9 is connected through the receiving plate 8, and the suction shell 9 is internally set There is a servo drive assembly 11, a shaft coupling 12 is installed on the side of the servo drive assembly 11 away from the receiving plate 8, a worm 13 is fixed inside the coupling 12, and...

Embodiment 2

[0038] like Figure 5 As shown in Comparative Example 1, another embodiment of the present invention is: the side of the knocking plate 26 away from the bent rod 25 is fixed with multiple groups of vibrating springs 27, and the vibrating springs 27 are far away from the knocking plate 26 One side of each is fixed with a knocking ball 28; during work, when the knocking plate 26 hits the guide plate 2, it will first drive the knocking ball 28 to hit the guide plate 2, and then vibrate the spring under the effect of the impact force 27 bends, thereby driving the knocking ball 28 to vibrate, and the knocking ball 28 will scratch the surface of the guide plate 2 during the vibration process, thereby cleaning the surface of the guide plate 2, and at the same time, the knocking plate 26 and the guide plate After the plate 2 is separated, under the action of the elastic force of the vibrating spring 27, a part of the percussion ball 28 will still collide with the guide plate 2, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com