Reactive blue-to-black dye composition and dye product

A technology of black dyes and dye compounds, applied in the field of reactive blue to black dye compositions and dye products, which can solve the problems of high COD of dyeing residue, increased sewage treatment pressure, low dye utilization rate, etc., and achieve extremely high dyeing depth And fixation rate, reduce the amount of dye, excellent effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

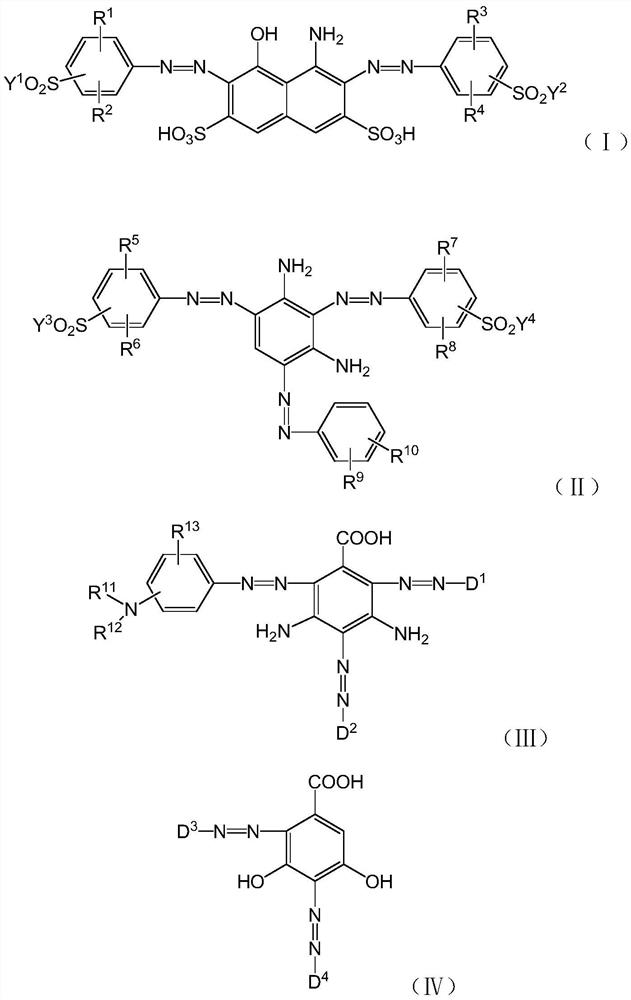

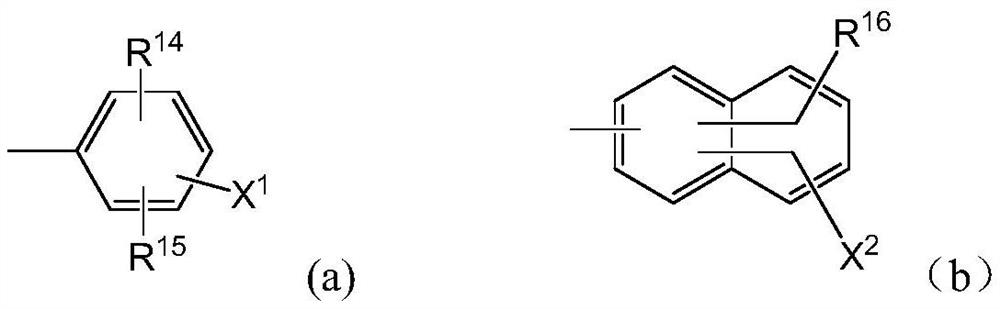

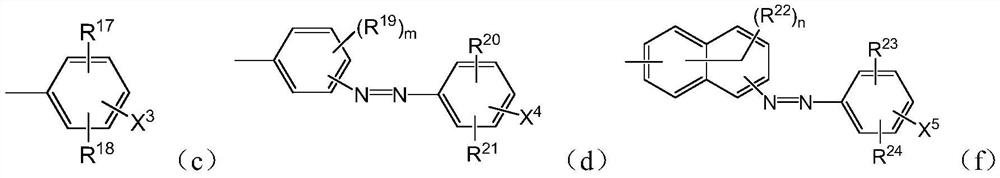

Method used

Image

Examples

Embodiment 1

[0132] Component A of 70 parts of formula (I-1) compound, component B of 20 parts of formula (II-1) compound, 5 parts of formula (III-1) and the component of 5 parts of formula (IV-26) compound C and 10 parts of sodium sulfate are mechanically mixed, and the obtained composite dye is dyed black by conventional exhaust dyeing method, and the color fastness to washing is above grade 4 (refer to GB / T 3921-2008), and the color fixation rate is above 75% ( Refer to GB / T2391-2014).

[0133]

[0134]

Embodiment 2

[0136]Component A of 65 parts of formula (I-1) compound, component B of 19 parts of formula (II-1) compound, 2 parts of formula (III-1) and the component of 5 parts of formula (IV-26) compound Component D of C, 9 parts of formula (Ⅴ-1) compound and 10 parts of sodium sulfate are mechanically mixed, and the composite dye obtained adopts the conventional exhaust dyeing method to dye cotton to be black, and the color fastness to washing reaches more than 4 grades (referring to GB / T 3921-2008), the color fixation rate is above 75% (refer to GB / T2391-2014).

[0137]

[0138]

Embodiment 3

[0140] 60 parts of component A of the compound of formula (I-1), 20 parts of component B of the compound of formula (II-1), 10 parts of component C of the compound of formula (III-1), 5 parts of component C of the compound of formula (V-1 ) and 5 parts of (Ⅵ-1) compound component D, and 10 parts of sodium bicarbonate are mechanically mixed, and the obtained composite dye is dyed black by conventional exhaust dyeing method, and the color fastness to washing is above grade 4 (refer to GB / T 3921-2008), the color fixation rate is above 75% (refer to GB / T2391-2014).

[0141]

[0142]

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com