Preparation method of hops-flavored full-amino-acid low-alcohol beer

A low-alcohol beer and amino acid technology, which is applied in the field of beer brewing, can solve the problems affecting the stability and coordination of beer, lack of distinctive taste, and loss of beer characteristics, so as to achieve rich amino acid content in beer, improve foam retention, and promote gelatinization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

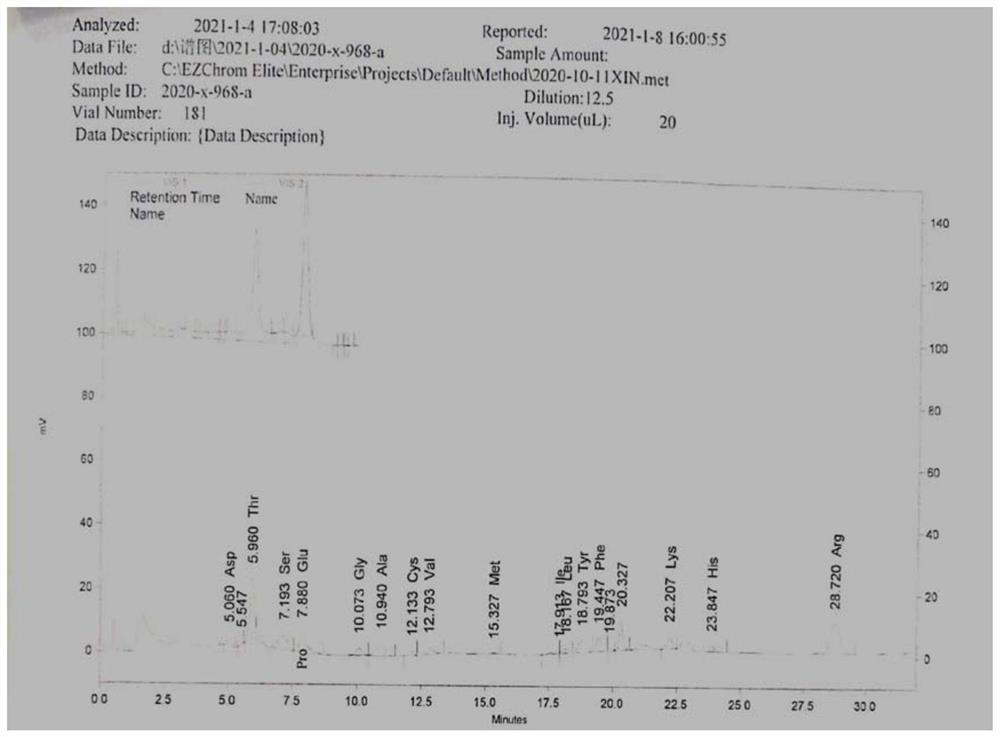

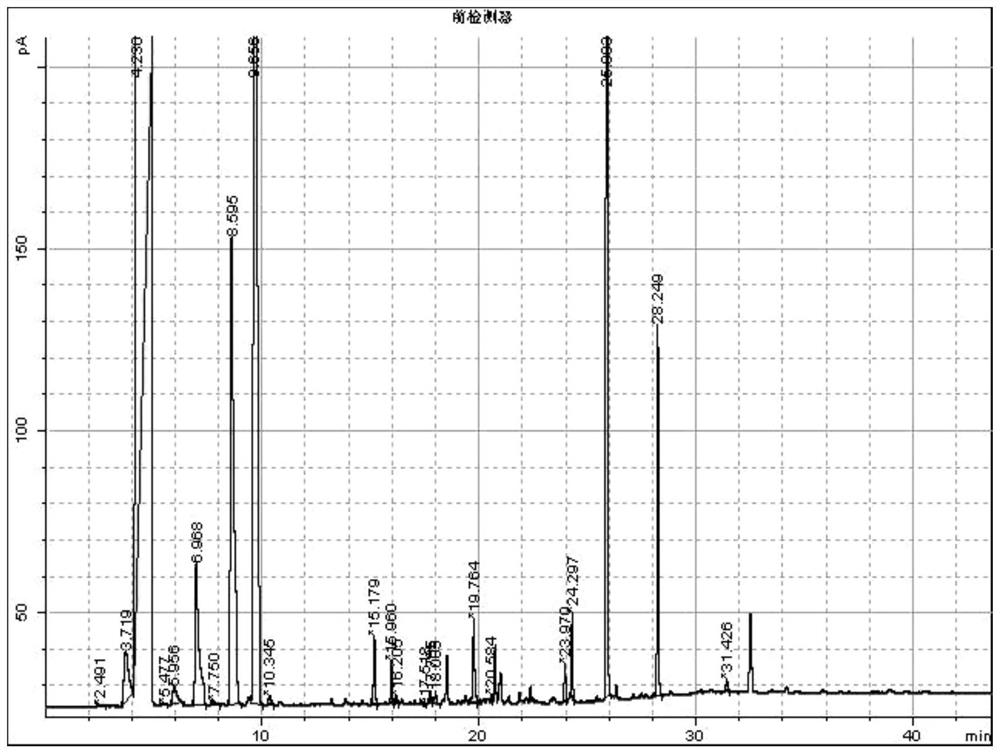

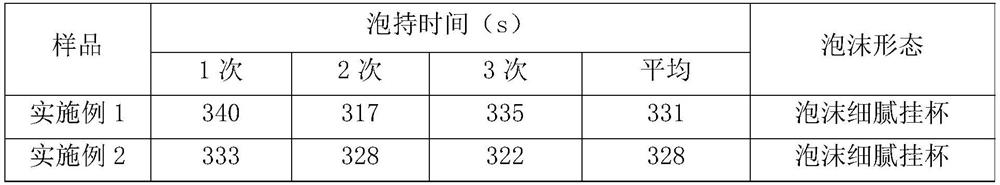

Embodiment 1

[0044] A hop-flavored all-amino acid low-alcohol beer, comprising raw materials: 75% of pilsner malt, 10% of wheat malt, 10% of caramel malt, and 5% of quinoa, all of which are in mass percentage. The preparation method comprises the following steps:

[0045] (1) Quinoa pretreatment: Mix Pearson malt, wheat malt and caramel malt, then humidify and pulverize to obtain mixed malt; put quinoa in a gelatinization pot, soak in water for 12 hours, remove the water, and then add water again, The mass ratio of material to water is 1:4, the temperature is raised to 45°C, and partly crushed mixed malt is added in an amount of 20wt% of the total amount of mixed malt, the temperature is raised to 72°C and kept for 20 minutes, then heated to 100°C, and kept for 20 minutes to obtain quinoa Liquid;

[0046] (2) Put the remaining crushed mixed malt into the mash pot, add water, the mass ratio of material to water is 1:4, the feeding temperature is 52°C, keep it for 30 minutes, then add the qu...

Embodiment 2

[0060] A hop-flavored all-amino acid low-alcohol beer, comprising raw materials: 70% of pilsner malt, 10% of wheat malt, 10% of caramel malt, and 10% of quinoa, all of which are in mass percentage. The preparation method comprises the following steps:

[0061] (1) Quinoa pretreatment: Mix Pilsner malt, wheat malt and caramel malt, then humidify and pulverize the mixed malt; put the quinoa in the gelatinization pot, add water to soak for 6 hours, remove the water, and then add water again, The mass ratio of material to water is 1:3, the temperature is raised to 45°C, and partly crushed mixed malt is added in an amount of 30wt% of the total amount of mixed malt, the temperature is raised to 70°C and kept for 15 minutes, then heated to 100°C and kept for 30 minutes to obtain quinoa Liquid;

[0062] (2) Put the remaining crushed mixed malt into the mash pot, add water, the mass ratio of material to water is 1:5, and the feeding temperature is 50°C, keep it for 40 minutes, then add...

Embodiment 3

[0072] A hop-flavored all-amino acid low-alcohol beer, comprising raw materials: 60% of pilsner malt, 10% of wheat malt, 10% of caramel malt, and 20% of quinoa, all of which are in mass percentage. The preparation method comprises the following steps:

[0073] (1) Quinoa pretreatment: Mix Pilsner malt, wheat malt and caramel malt, then humidify and pulverize the mixed malt; put the quinoa in the gelatinization pot, add water to soak for 24 hours, remove the water, and then add water again, The mass ratio of material to water is 1:4, the temperature is raised to 45°C, and partly crushed mixed malt is added in an amount of 20wt% of the total amount of mixed malt, the temperature is raised to 72°C and kept for 30 minutes, then heated to 100°C, and kept for 15 minutes to obtain quinoa Liquid;

[0074] (2) Put the remaining crushed mixed malt into the mash pot, add water, the mass ratio of material to water is 1:4, the feeding temperature is 52°C, keep it for 30 minutes, then add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com