Load distribution method for roller washing machine

A drum washing machine and load distribution technology, which is applied in the control device, washing device, textile and paper making of washing machine, etc., can solve the problems of unevenness, unbalance, and high water content of the laundry, so as to improve the distribution effect, avoid eccentricity, improve the effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

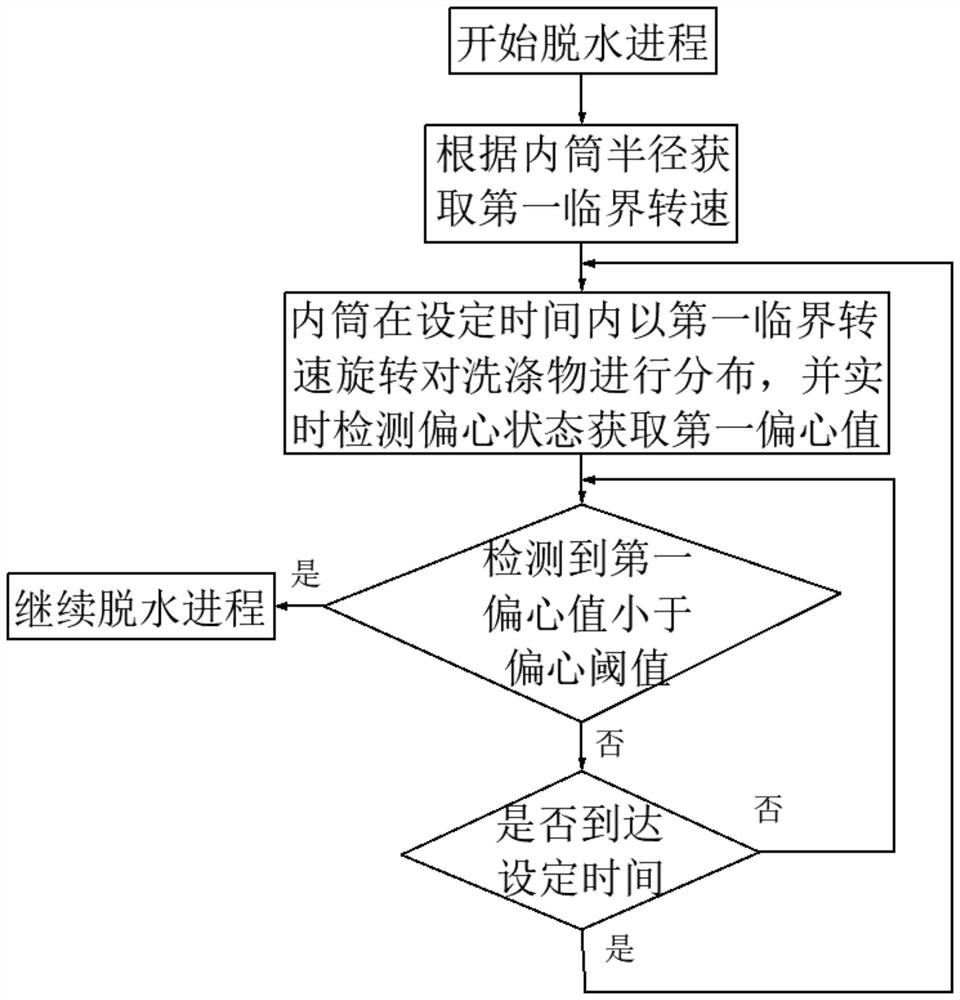

[0048] As an embodiment of the present invention, this embodiment provides a load distribution method for a drum washing machine, including:

[0049] S1. After starting the dehydration process, control the inner cylinder to rotate at a critical speed within the set time to distribute the laundry;

[0050] S2. Real-time detection of the eccentric state during the rotation of the inner tub at the critical speed to obtain the first eccentricity value, which is always greater than the preset eccentricity threshold, and return to step S1 to redistribute the laundry.

[0051] In this embodiment, the critical speed is the first critical speed, and the radius of the inner cylinder is brought into the formula Mω 2 R=Mg, calculate the angular velocity ω, and then convert the angular velocity ω into rotational speed.

[0052] The above scheme compares the motion state of the laundry when it is dehydrated in the inner cylinder to the state of the object when it is orbiting on the surface...

Embodiment 2

[0055] As another embodiment of the present invention, this embodiment makes further improvements on the basis of Embodiment 1 in order to improve the distribution efficiency of laundry, as follows:

[0056] In this embodiment, in order to improve the distribution efficiency of the laundry, in step S1, the inner tub first rotates at a speed lower than the critical speed within a set time, and then accelerates to the critical speed to rotate. In the above scheme, if the distribution is carried out at the critical speed at the beginning, it will take a long time for the laundry to be completely evenly distributed, and it may even be impossible to distribute the laundry due to too fast starting speed; the laundry is rotated at a speed less than the critical speed After the initial distribution in the inner cylinder, it is accelerated to the critical speed for further distribution, which further improves the dispersion efficiency and dispersion effect.

[0057] Further, in step S1...

Embodiment 3

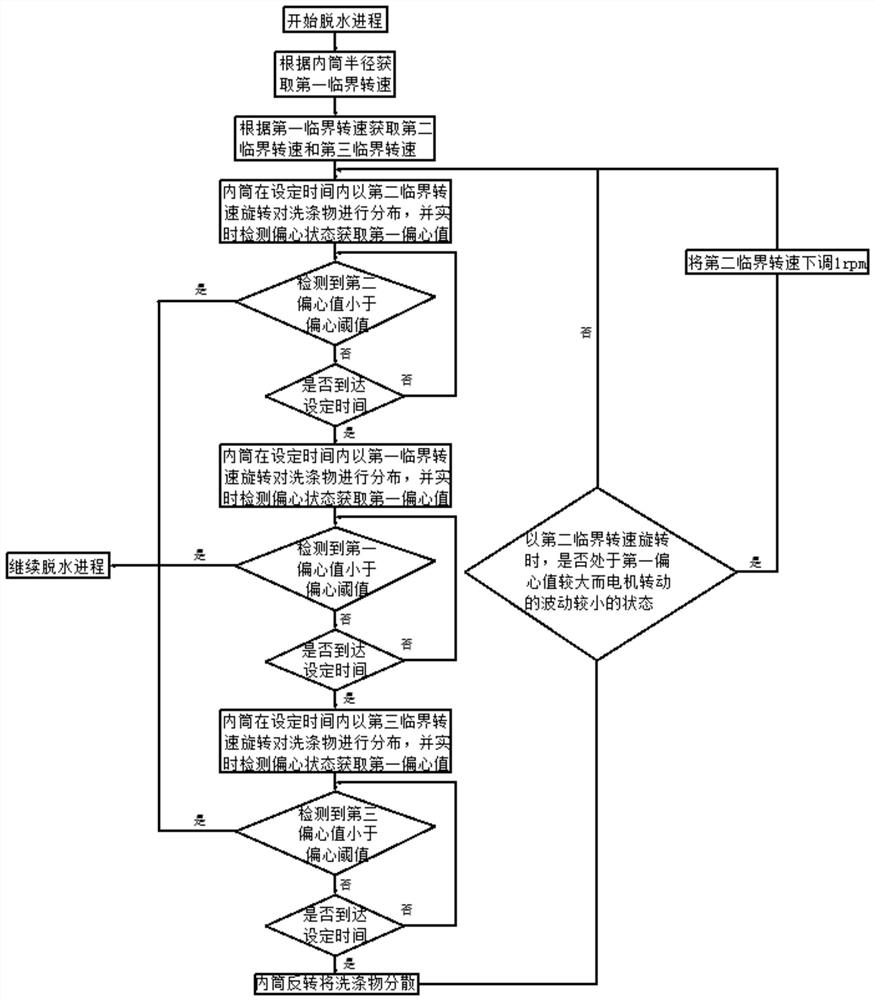

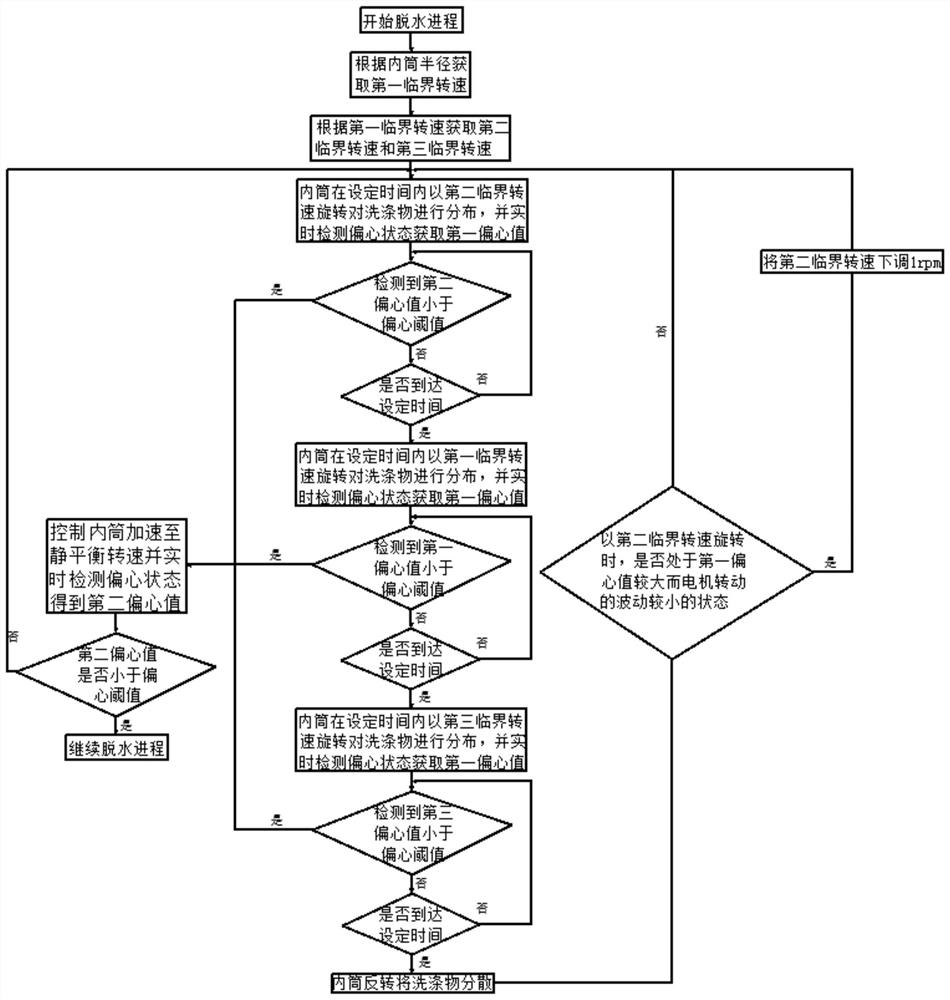

[0060] As another embodiment of the present invention, this embodiment provides a load distribution method for a front-loading washing machine, the steps of which are the same as in Embodiment 1, except that:

[0061] In this embodiment, the critical speed includes,

[0062] The first critical rotational speed is obtained by converting the angular velocity ω into the rotational speed;

[0063] The second critical speed is adjusted upwards based on the first critical speed;

[0064] The third critical speed is adjusted downward on the basis of the first critical speed;

[0065] In the step S2, when the laundry is distributed multiple times, the laundry is distributed at different critical rotational speeds.

[0066] In the above scheme, the first critical speed is calculated by bringing the radius R of the inner cylinder and the acceleration of gravity g into the formula of universal gravitation. However, during the distribution process of the laundry, the distance from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com