Concrete building surface defect repairing device and repairing method thereof

A defect repair, body surface technology, applied in building maintenance, construction, building construction, etc., can solve problems such as low repair efficiency, inability to realize automatic processing, and repair operation danger, etc., to improve efficiency, improve repair efficiency, reduce dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

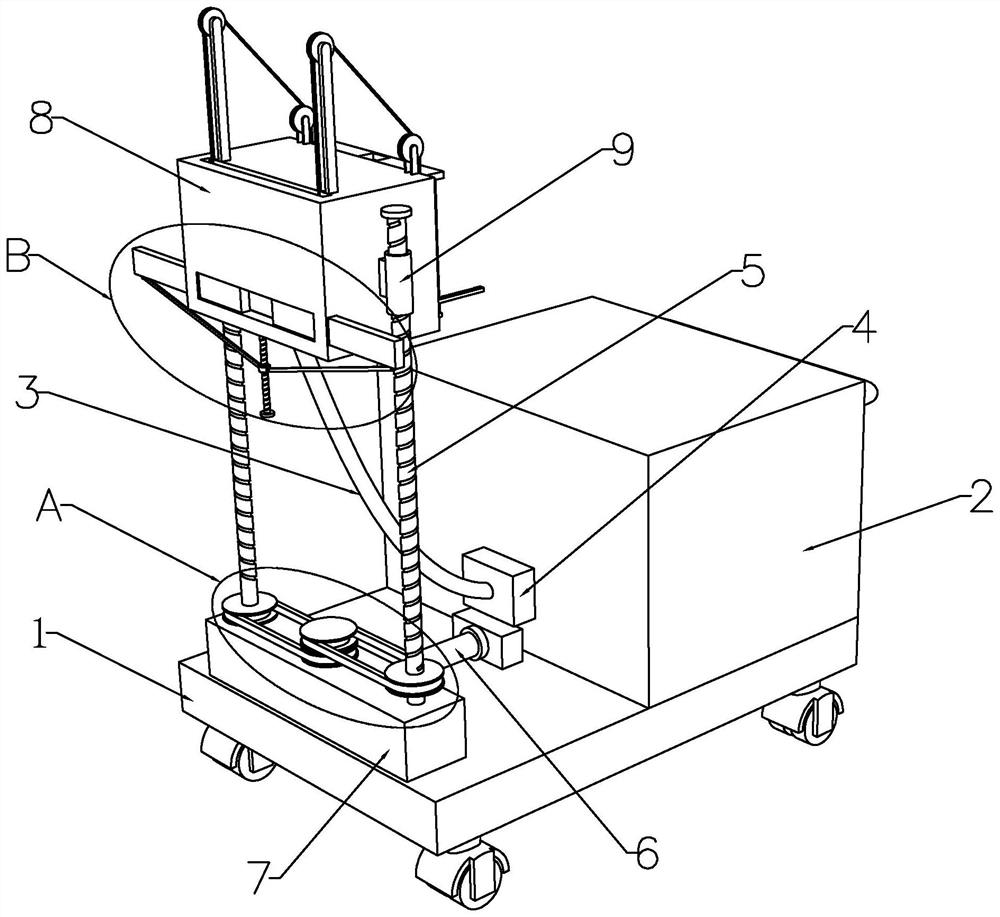

[0038] refer to figure 1 , a device for repairing surface defects of concrete buildings, including a mobile car body 1, a raw material box 2 is fixedly installed on one side of the top end of the mobile car body 1, and a raw material box 2 is fixedly installed on the other side facing the mobile car body 1 The first electric telescopic rod 6 , the end of the first electric telescopic rod 6 is fixedly connected with the movable base 7 , and the movable base 7 is slidably installed on the top end of the mobile vehicle body 1 .

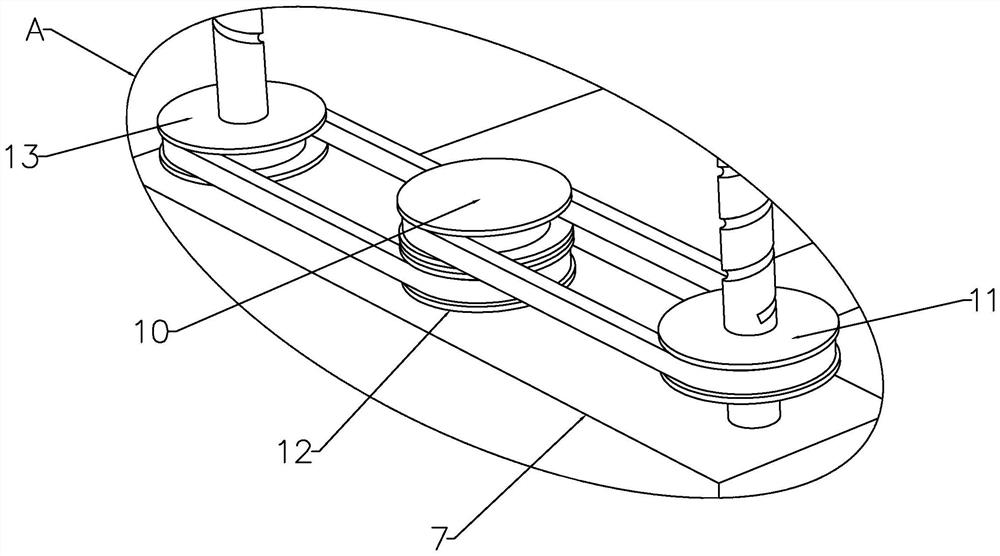

[0039] refer to figure 1 and figure 2, both sides of the top of the movable base 7 are rotatably equipped with a lifting screw 5, and a driving mechanism is arranged between the movable base 7 and the lifting screw 5, and the driving mechanism includes a driving motor, a first main pulley 10, a first secondary pulley 11, a Two primary pulleys 12 and the second secondary pulley 13, the inside of the movable base 7 is fixedly installed with a drive moto...

Embodiment 2

[0046] refer to Figure 8 , the top of the repair box 8 is provided with a limit groove, and the inner wall of the repair box 8 near the discharge port 14 is slidably equipped with a baffle plate 32, and the limit groove matches the baffle plate 32, and the top of the baffle plate 32 is aligned with the first movable plate. Two traction wire ropes 27 that are symmetrically distributed are connected between the tops of 19, and the top of the repair box 8 is provided with a guiding mechanism that cooperates with the traction wire ropes 27.

[0047] refer to Figure 6 and Figure 8 , the guide mechanism includes a first mounting frame 29, a first guide wheel 28, a second mounting frame 31 and a second guiding wheel 30, and the top of the repair box 8 is fixedly equipped with two groups of first mounting frames 29 and two groups of symmetrically distributed The second installation frame 31 that is symmetrically distributed, and the first guide wheel 28 is installed on the top of...

Embodiment 3

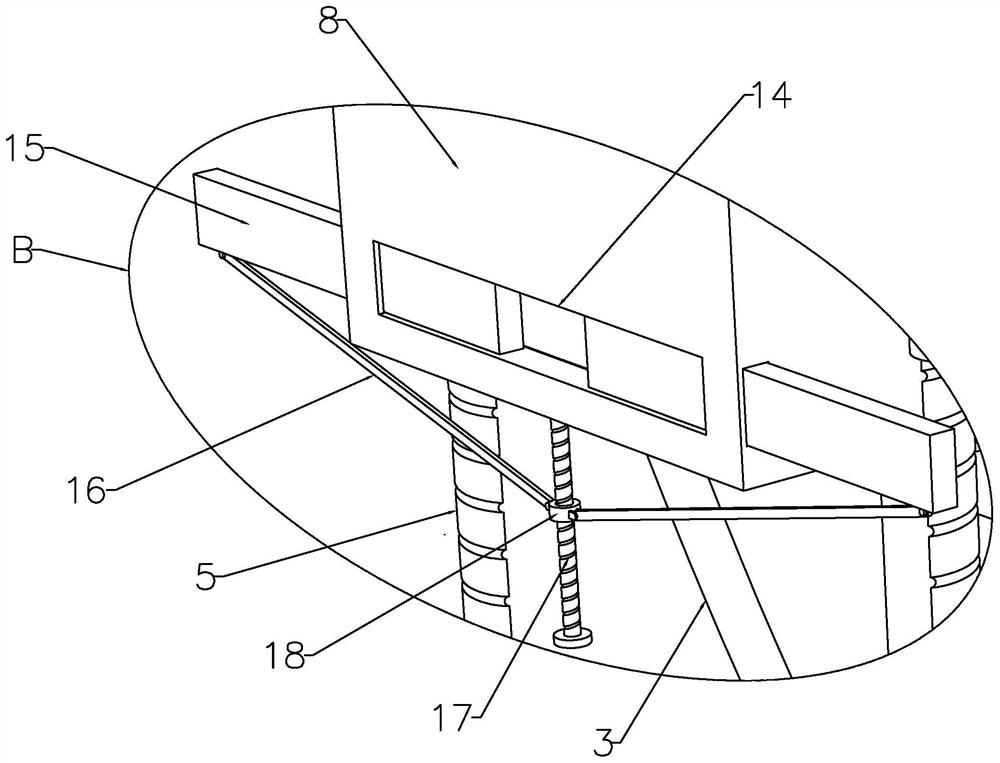

[0050] refer to image 3 , the both sides of the repair box 8 are slidingly installed with material limiting plates 15 that are symmetrically distributed, and the end of the material limiting plate 15 extends to the inside of the discharge port 14, and the bottom end of the repairing box 8 is provided with the material limiting plate 15. the adjustment mechanism.

[0051] refer to image 3 , the adjustment mechanism includes a hinged rod 16, an adjustment screw 17 and an adjustment collar 18, the bottom of the repair box 8 is rotated with an adjustment screw 17, and the threaded sleeve on the rod body of the adjustment screw 17 is provided with an adjustment collar 18, and the adjustment collar 18 A hinged rod 16 is hingedly installed between the two sides of each and the bottom ends of the two material limiting plates 15 respectively.

[0052] This embodiment adds a mechanism for adjusting the diameter of the discharge port 14 on the basis of the first and second embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com