Multi-layer light bulletproof armor with composite structure

A composite structure and bulletproof technology, applied in armor, armored vehicles, protective equipment, etc., can solve the problems of not meeting the requirements of modern bulletproof armor, low bonding strength of ceramics and backplate, and difficulty in withstand collisions, so as to improve combat effectiveness, Good weather resistance, the effect of reducing kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

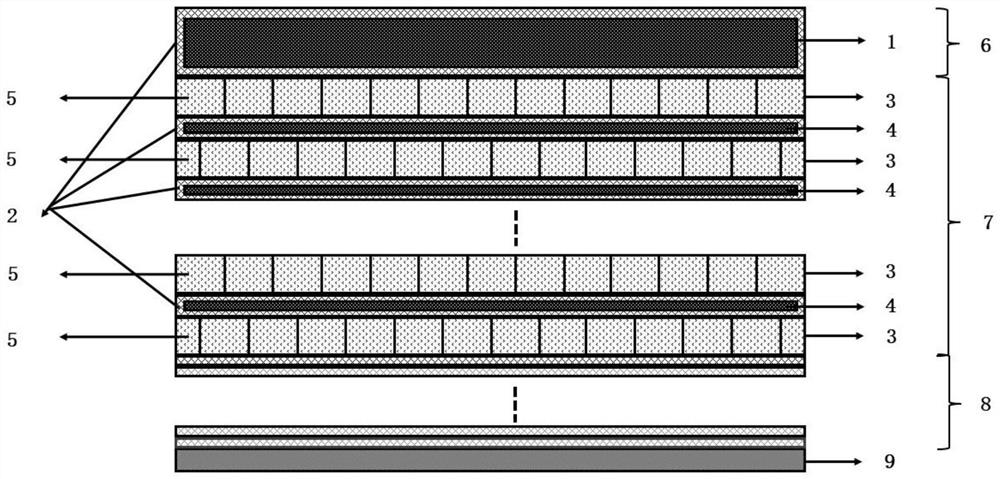

[0025] The invention discloses a multilayer lightweight composite structure bulletproof armor. The bulletproof armor consists of bomb-receiving layer, energy-absorbing and shock-absorbing layer, fiber buffer layer and bullet-proof back plate from outside to inside, wherein the bomb-receiving layer is a ceramic plate wound with PE fiber; the energy-absorbing and shock-absorbing layer is a ceramic plate wound with PE fiber Alternately arranged with metal honeycomb panels filled with high-elastic resin-based composite materials, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap